Stable acid inhibitor formulations with improved performance, lower toxicity and minimal environmental issues

a technology of acid inhibitors and formulations, which is applied in the field of corrosion inhibitors, can solve the problems of affecting the performance of acid inhibitors, affecting the stability of acid inhibitor formulations, so as to achieve greater metal corrosion protection and improve shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

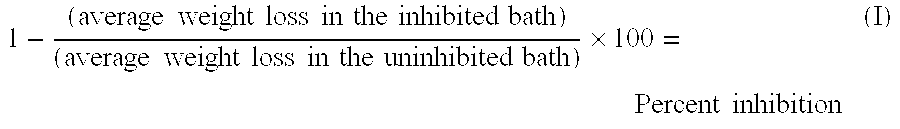

Method used

Image

Examples

examples

[0057] The following illustrate various embodiments of this invention and are not intended as limiting. An aqueous acid inhibitor concentrate according the invention (Example 1) and an aqueous acid inhibitor concentrate according to the prior art (Comparative Example 1) were formulated as shown in Table 1:

TABLE 1Formulations of aqueous acid inhibitor concentratesAmount (parts by weight)IngredientComparativeCategoryIngredientExample 1Example 1AProtein hydrolysate (Rousselot12.0012.0092B, a product of RousselotInc. of Dubuque, IA)BNonylphenoxypolyethyleneoxy1.400ethanol - iodine complexproviding at least 20%available iodine (Biosurf I-20,a product of Lonza Group Ltd.Switzerland)BEthylene diamine dihydroiodide3.273.27CPolyoxyethylene (20) sorbitan4.04.0monooleate (“Tween 80”, aproduct of ICI Americas, Inc.,Wilmington DECNonylphenoxypolyethyleneoxy9.830ethanol (Igepal CO-660, aproduct of Stepan Company,Northfield, IL)DPropylene Glycol7.57.5EPhosphoric Acid, 75% aq. Sol.2.02.0—Waterq.s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com