Coating materials, method for the production thereof, and use thereof

a coating material and coating technology, applied in the direction of coatings, organic dyes, etc., can solve the problems of lack of indications of scratch resistance, comparatively difficult application of coating materials, etc., to achieve outstanding performance properties, high scratch resistance, and high resistance to pancreatin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0165] The preparation of a methacrylate copolymer (A)

[0166] A laboratory reactor with a useful volume of 4 l, equipped with a stirrer, two dropping funnels for the monomer mixture and initiator solution respectively, a nitrogen inlet pipe, thermometer, and reflux condenser, was charged with 601 g of an aromatic hydrocarbons fraction having a boiling range from 158° C. to 172° C. The solvent was heated to 140° C. When 140° C. had been reached, a monomer mixture of 225.4 g of styrene, 169 g of n-butyl methacrylate, 293 g of cyclohexyl acrylate, 225.4 g of hydroxypropyl methacrylate, 202.8 g of 2-hydroxyethyl methacrylate and 11.2 g of acrylic acid was metered into the reactor at a uniform rate over the course of 4 hours and an initiator solution of 112.6 g of t-butyl perethylhexanoate in 40 g of the aromatic solvent described was metered into the reactor at a uniform rate over the course of 4.5 hours. The metering of the monomer mixture and of the initiator solution was commenced si...

preparation example 2

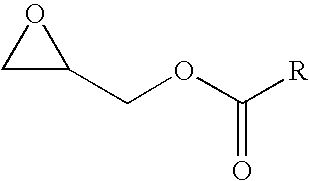

[0167] The Preparation of a Methacrylate Copolymer (B) Containing Hydroxyl and Carbamate Groups

[0168] A laboratory reactor having a useful volume of 4 l, equipped with a stirrer, two dropping funnels for the monomer mixture and initiator solution respectively, a nitrogen inlet pipe, thermometer, and reflux condenser, was charged with 176.7 g of an aromatic hydrocarbons fraction having a boiling range from 158° C. to 172° C., 188.8 g of methyl carbamate and 345.9 g of Cardura® E-10 (glycidyl ester of Versatic® acid, from Shell Chemie) The solvent was heated to 140° C. After 140° C. had been reached, a monomer mixture of 312 g of hydroxyethyl methacrylate, 85.4 g of cyclohexyl methacrylate, 117.41 g of methacrylic acid and 59.6 g of the aromatic solvent described and an initiator solution of 73.9 g of azoisovaleronitrile in 36.7 g of xylene were metered into the reactor at a uniform rate over the course of 1 hour. The reactor was furnished with a distillation bridge. Then a solution ...

example

Preparation of a Clearcoat Material and Production of a Clearcoat

[0169] 175 g of the methacrylate copolymer solution (A) of preparation example 1, 352 g of methacrylate copolymer solution (B) from preparation example 2, 194 g of a butanol-etherified melamine resin (Cymel® 1158 from Cytec), 12 g of a blocked acid catalyst (Nacure® 2500 from King Industries), 10 g each of Tinuvin® 248 and 123 (light stabilizers from Ciba), 2 g of a commercial leveling assistant (silicone oil) and 212 g of xylene were mixed thoroughly. The ratio of hydroxyl groups to carbamate groups in the clearcoat material was 1:0.8, and 77% by weight of the hydroxyl groups present in the binders (A) and (B) were primary hydroxyl groups.

[0170] The clearcoat material was applied wet-on-wet to test panels which had been coated with black aqueous base coat films. The resultant aqueous base coat films and clearcoat films were baked at 140° C. for 20 minutes to give test panels bearing multicoat paint systems composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

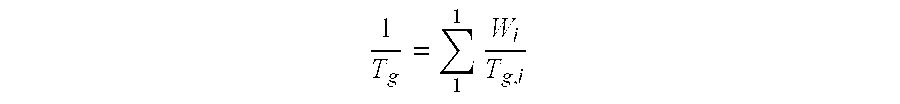

| glass transition temperature | aaaaa | aaaaa |

| number-average molecular weight Mn | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com