High strength steel product with improved formability and steel manufacturing process

a technology of high strength steel and manufacturing process, applied in the field of high strength steel products, can solve the problems of material becoming harder, increasing the difficulty of further thickness reduction by rolling, and increasing the difficulty of material shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The process according to the present invention preferably utilizes many of the same process steps and apparatus as modern thin slab and medium slab processes for producing flat rolled steel products. Typical processes of this type utilize a furnace to produce molten steel, at least a portion of which may comprise scrap material. The molten steel is cast, preferably on a continuous basis, to produce a slab having a thickness of from about 30 to about 200 mm. According to the present invention, It is preferred that the hot as-cast slab is directly charged into a reheating or equalizing furnace to prevent excessive cooling. However, the process of the invention is also compatible with processes in which the as-cast slab is allowed to cool before further processing.

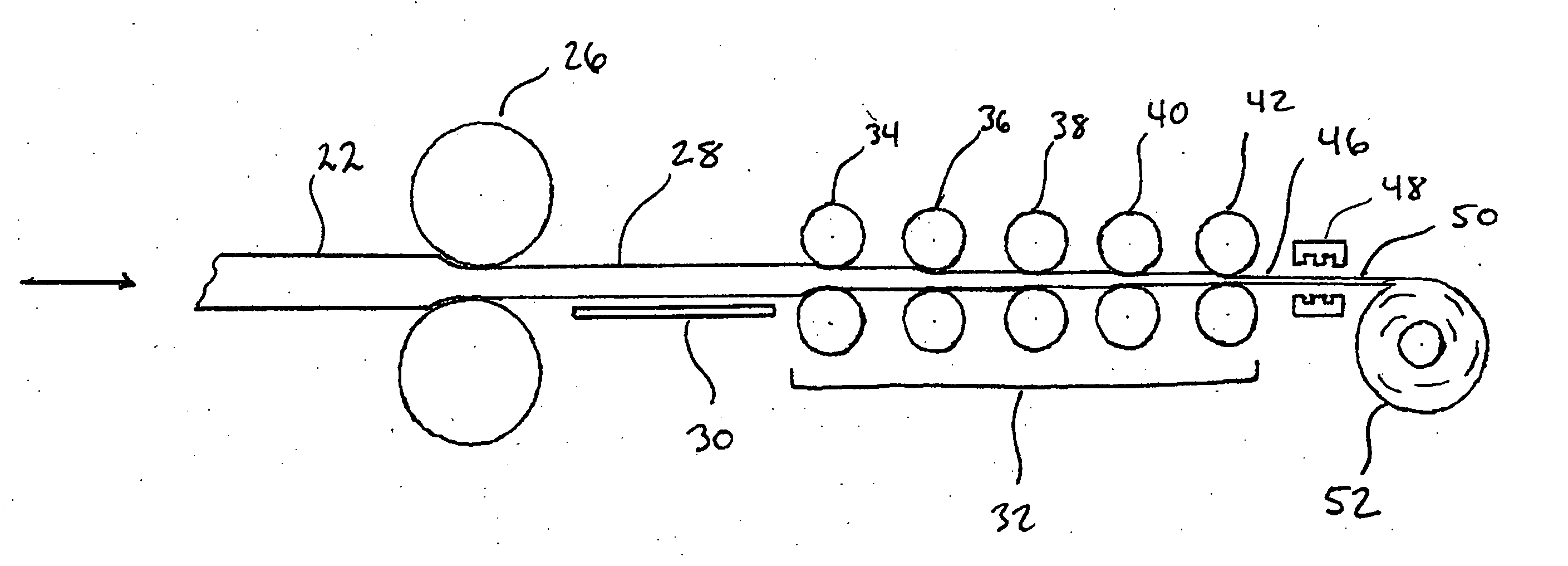

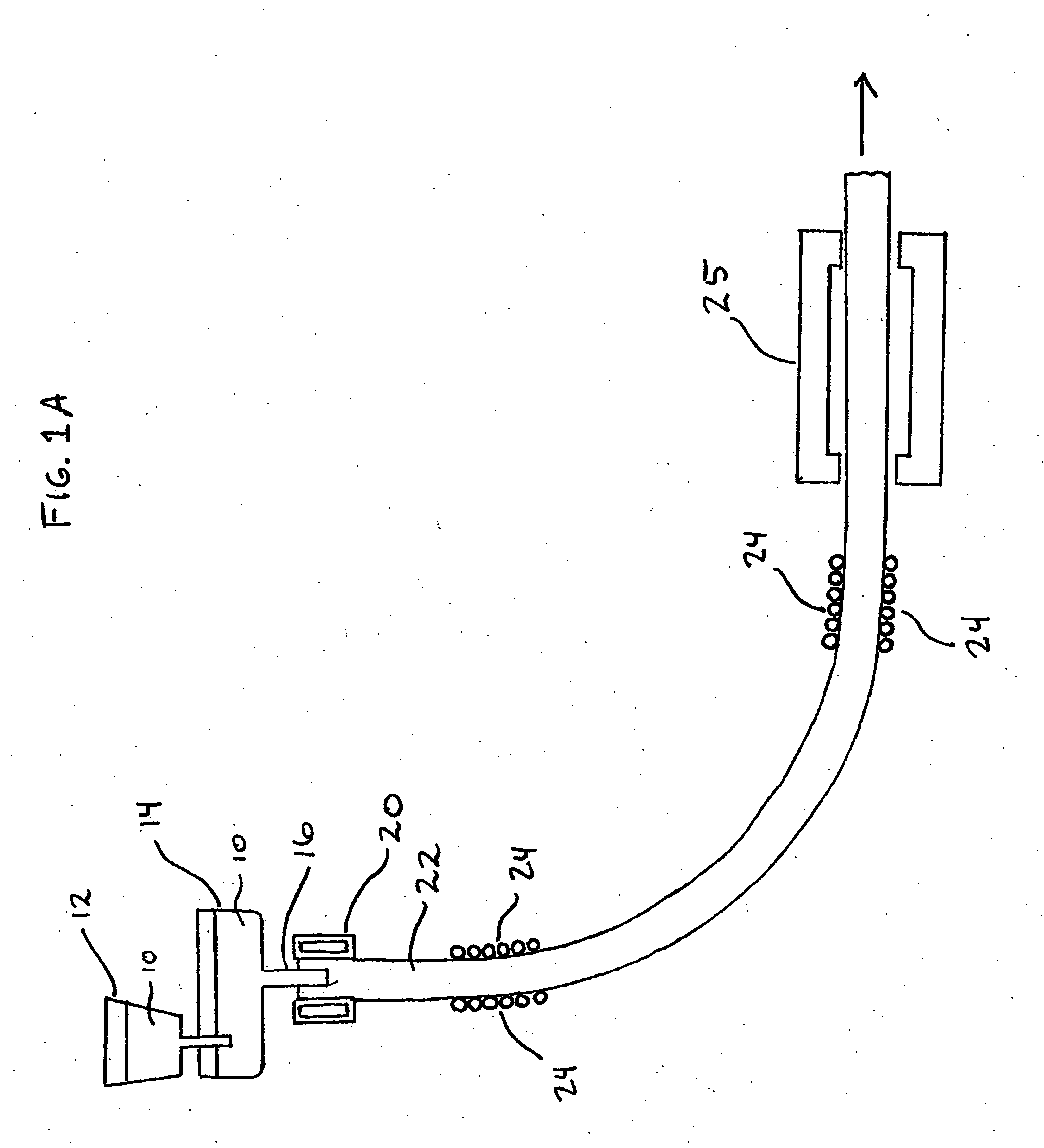

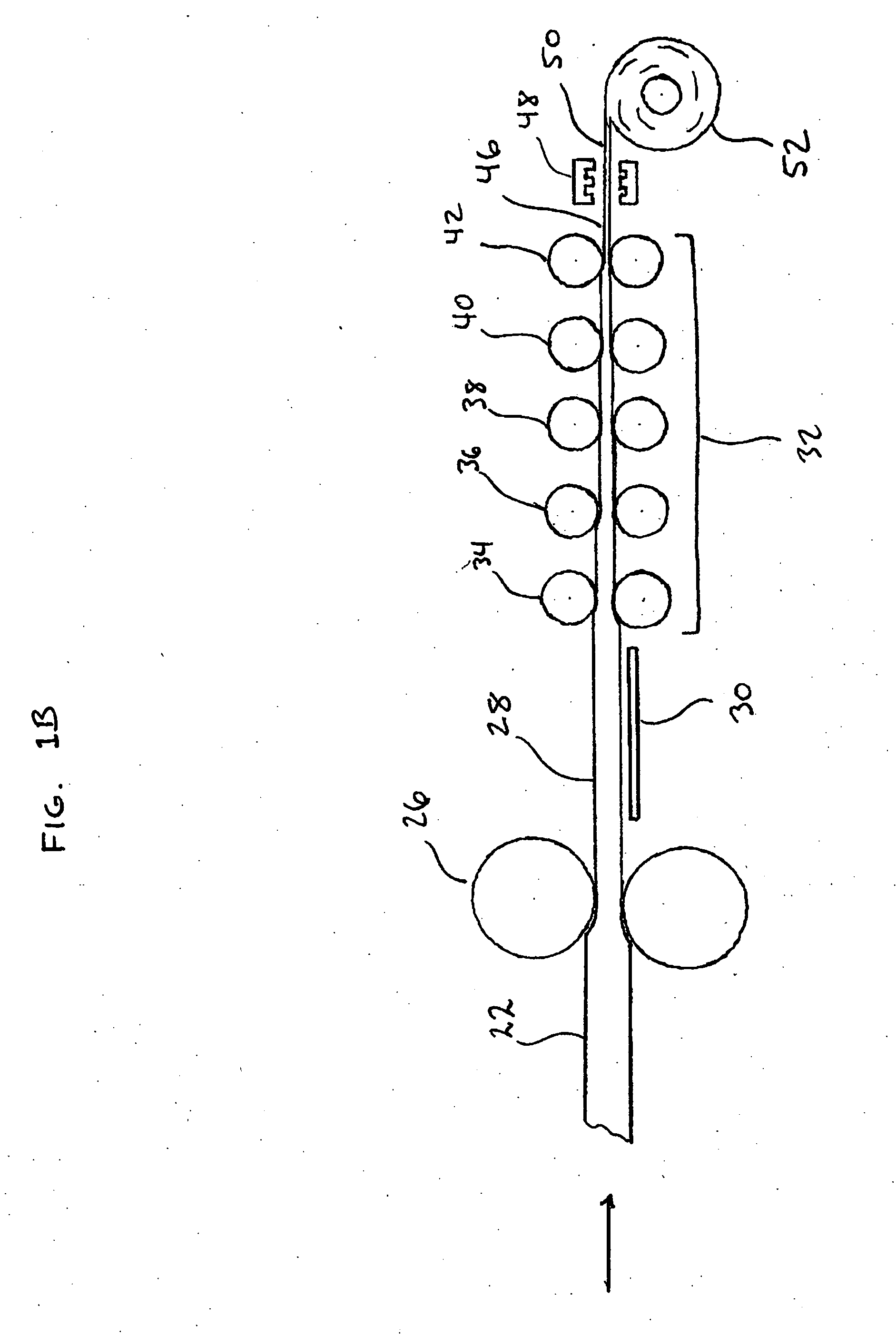

[0027] A preferred process and apparatus according to the present invention are schematically illustrated in FIG. 1. As in known thin slab and medium slab casting processes, molten steel 10 is produced in a furnace (n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com