Bullet with booster filling and its manufacture

a technology of booster filling and bullets, applied in the field of bullets, can solve the problems of small increase in velocity, severe distortion of high-speed bullets fired into liquids like water or living tissue, and ineffective increase of penetration, so as to prevent the hollow point of a bullet and increase the expansion of the bull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

[0227] Two prototype ammunition designs were developed and tested to illustrate the possibilities of basing a new bullet design on the invention disclosed herein.

[0228] One is low penetration ammunition. For home defense, ammunition that is issued to personnel with little training in defense or that is employed in crowded areas should be convenient to use and have the following features: good stopping power, i.e., stopping power equivalent to a military (e.g., NATO) ammunition would be the minimum acceptable; low penetration of intermediate barriers, i.e., although police require high penetration of cars in defensive applications, not only would this feature be unnecessary but it may be a handicap in crowded areas or in home defense applications; and low report, i.e., a loud report like that of a 9 mm NATO round may produce permanent hearing damage, while a report that is three decibels (dB) less would make the report acceptable.

[0229] The second is ammunition for police applicati...

working example no.1

Working Example No. 1

[0230] Thin metal plate penetration increases with the square power of velocity and decreases with the bullet's frontal surface area. If the only desired feature of a bullet is a low thin metal plate penetration, bullet velocity can be reduced as necessary by reducing the powder load. Automatic pistol ammunition must produce sufficient recoil to operate the slide. Recoil is a linear function of bullet mass and velocity. The maximum bullet mass is limited by the cartridge design. Bullets have a maximum possible length (and mass) limited by the cartridge dimensions, as the assembly cannot exceed a certain length. Comparing FIG. 39 with FIG. 40, it is noticeable in FIG. 39 that the bullet is longer (and heavier) and consequently smaller powder space 102 left in the case bellow the bullet is restricted. A ten percent increment in the bullet's mass would reduce the powder capacity by 50 percent, reducing the kinetic energy by the same amount, and the bullet would not...

working example no.2

Working Example No. 2

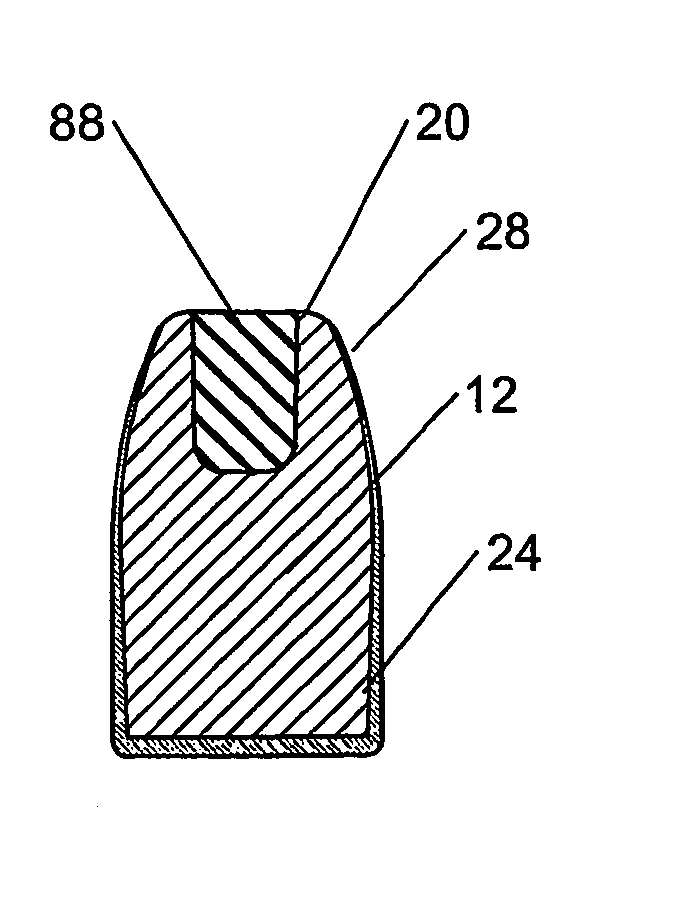

[0236] Referring to FIG. 40, another cartridge as a preferred embodiment of the invention is illustrated. In this embodiment, the cartridge comprised powder filling space 100 and second prototype bullet 160 having cavity filled with elastomer 42, both of which were situated in case 97. Second prototype bullet 160 was comprised of a plain lead alloy with six percent antimony and had a weight of 7.5 grams. Because no jacket was provided, embodiments of second prototype bullet 160 were either copper clad or Teflon® coated. The hollow point had a cavity that was 3.75 in diameter by 9.5 mm in length and contained elastomer filling 42 in accordance with the invention disclosed herein.

[0237] Upon striking a liquid target at a velocity of 350 m / sec, bullet 160 expanded to sixteen mm, compared to a 12 mm expansion for a Silver Tip® bullet, producing a pressure wave intensity that was 40 percent higher. In that the expanded ring disintegrated after reaching maximum expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com