Mass production of shells and models for dental restorations produced by solid free-form fabrication methods

a manufacturing method and dental restoration technology, applied in the field of dental restorations, can solve the problems of affecting strength and reliability, reducing the skill time required, and requiring extensive labor and time for the fabrication of current all-ceramic dental restorations, and achieving the effect of promoting powder particle binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0058] Filament is prepared from Investment Casting Wax (ICW06, Stratasys) and thermoplastic ABS (P400, Stratasys) and equiaxed alumina powder of 5 to 10 microns particle size. The binder content is about 30 volume percent.

[0059] Using a CAD / CAM device and digitizer manufactured by CAD / CAM Ventures (Irving, Tex.), the model of a tooth preparation is digitized and the obtained CAD file is used in conjunction with an FDM2000 fused deposition modeling machine available from Stratasys Inc. (Eden Prairie, Minn.). Using the filament containing equiaxed alumina powder in a thermoplastic matrix, single and multiunit dental restorations are formed and then subjected to binder-removal and soft-sintering cycles. The resulting porous preforms are infiltrated with glass using materials supplied by Vita Zahnfabrick (Bad Sackingen, Germany) and glass infiltration techniques used for Vita In-Ceram Alumina restorations.

example 2

[0060] The same CAD file as used in Example 1 is used in conjunction with a three-dimensional printing machine such as the Z402 System available from Z Corporation (MA) to print on ceramic powder and on metal powder separately. The same powder-binder mixture used above is used herein as the powder layer. A binder mixed with finely dispersed pigments is printed on the powder layer. Successive layers are deposited to form a dental restoration based on the CAD file. After the restoration is fully formed, the binder is burned out and glass is then infiltrated into the interstices. The pigment is retained in interstitial sites between the alumina particles to impart a shade to the composite.

example 3

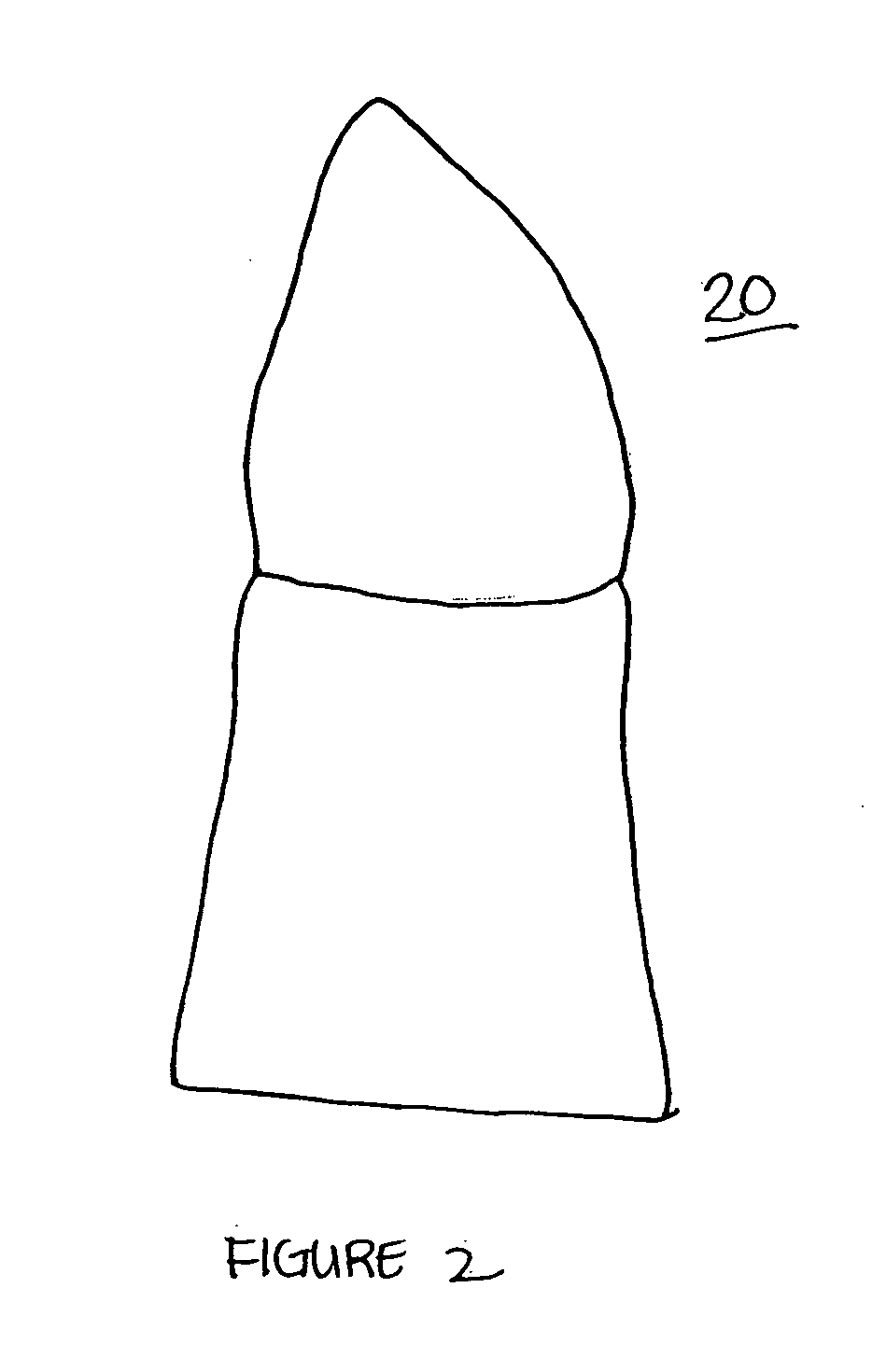

[0061] Using a CAD / CAM device and digitizer manufactured by CAD / CAM Ventures (Irving, Tex.), the model of a tooth preparation is digitized and the obtained CAD file is used to manufacture a shell. The CAD file is modified to provide a thickness in the shell great enough to support and withstand the refractory materials. The thickness of the shell varies from about 0.5 to about 10 mm in thickness. The shell produced is thinner near the margin and thicker near the apex. This information is fed into a computerized liquid wax dispensing machine. A green injection wax available from Romanoff Inc is injected into the machine. The wax is delivered as tiny beads in liquid state that solidify shortly after dispensing. The internal surface of the shell is smooth. The support structure of the shell is in the form of a solid or void-containing structure, such as a honeycomb structure. Polyvest refractory material available from WhipMix corporation is poured into the shell and sets. After settin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| droplet sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com