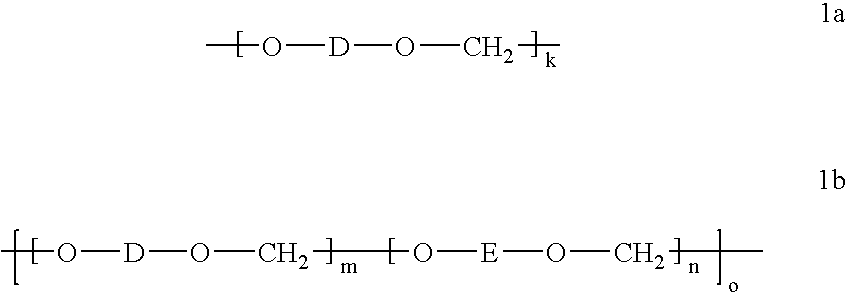

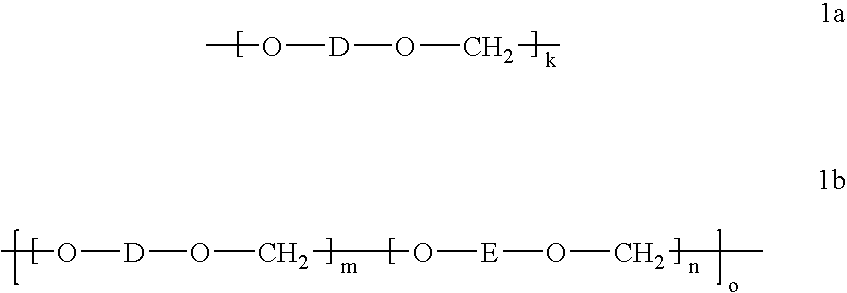

Branched polyformals and copolyformals their preparation and use

a polyformal and copolymer technology, applied in the field of thermoplastic molding compositions, can solve the problems of unsatisfactory properties, hydrolysis again represents a certain problem, and has a negative effect on the dimensional stability of data carrier materials, and achieves the effect of reducing the shear rate and high shear ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

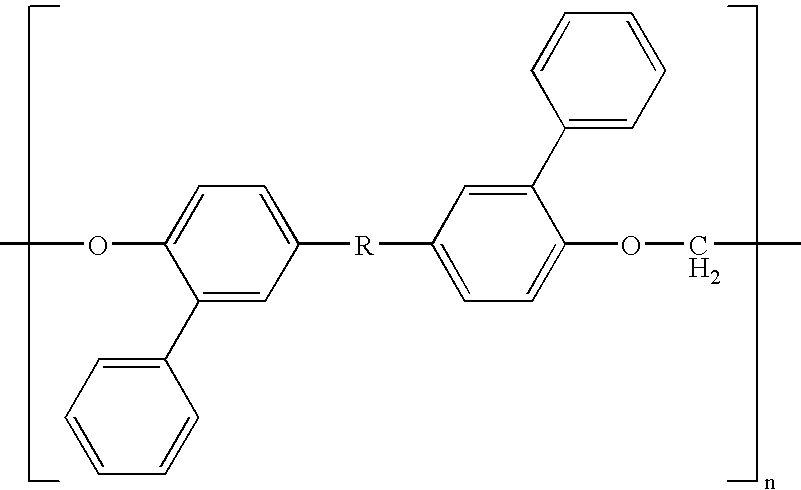

example 1

Long-chain branched homopolyformal from bisphenol A:

31.96 g (0.14 mol) bisphenol A (Bayer AG), 14.0 g (0.35 mol) sodium hydroxide lozenges, 0.21 g (0.0014 mol, 1 mol % with respect to bisphenol) of finely ground p-tert-butylphenol (Aldrich) and 0.193 g (0.00056 mol, 0.4 mol % with respect to bisphenol) isatin-biscresol (IBC) are added to a solvent mixture of 125 ml methylene chloride and 225 ml N-methyl-2-pyrrolidone (NMP), while stirring and under nitrogen as an inert gas. After homogenization, the mixture is heated to the reflux temperature (78° C.) and stirred at this temperature for one hour. After cooling down to 25° C., the reaction mixture is diluted with methylene chloride and demineralized water. The organic phase is then washed neutral and salt-free (conductivity<15 μS.cm-1) with water. The polymer is finally precipitated in methanol. After rinsing with methanol and drying in a vacuum drying cabinet at 80° C., 29.2 g of white polyformal are obtained. The polymer, ...

example 2

Long-chain branched copolyformal from bisphenol A and bisphenol TMC:

5.432 kg (17.5 mol) bisphenol TMC (x=70 mol %), 1.712 kg (7.5 mol) bisphenol A (y=30 mol %, 2.5 kg (62.5 mol) sodium hydroxide lozenges, 56.33 g (0.375 mol, 1.5 mol % with respect to bisphenol) of finely ground p-tert-butylphenol (Aldrich) in 500 ml methylene chloride and 43.175 g (0.125 mol, 0.5 mol % with respect to bisphenol) isatin-biscresol (IBC) are added to a solvent mixture of 28.7 kg methylene chloride and 40.18 kg N-methyl-2-pyrrolidone (NMP), while stirring and under nitrogen as an inert gas. After homogenization, the mixture is heated to the reflux temperature (78° C.) and stirred at this temperature for one hour. After cooling down to 25° C., the reaction mixture is diluted with methylene chloride and demineralized water. The mixture is washed neutral and salt-free (conductivity<15 μS.cm−1) with water in a separator. The organic phase from the separator is separated off and the solvent exchange...

example 3

Long-chain branched copolyformals from bisphenol A and bisphenol TMC:

Further branched copolyformals are prepared analogously to example 2. They differ only in the amount of branching agent IBC employed:

Analysis:

a) Amount of IBC (0.6 mol %): Molecular weight Mw=42,796, Mn=20,075 according to GPC (calibration against polycarbonate).

b) Amount of IBC (0.7 mol %):

Molecular weight Mw=43, 603, Mn=20,098 according to GPC (calibration against polycarbonate).

Properties of the Polymers:

Determination of the viscosity as a function of the shear rate (ISO 11443) on the long-chain branched polymer sample from example 2:

The branched copolyformal obtained in example 2 is analysed rheologically at 260, 280 and 300° C. The capillary (D / L) here is 20. The following data are obtained in this analysis:

ShearViscosity / gradient [s−1]260° C. [Pas]280° C. [Pas]300° C. [Pas]504,6162,3391,3581003,2091,7431,0582002,1201,2477965001,1597395051,0007044693461,5005213592685,000246152117

Determinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| hydrolytic stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com