Film forming liquid injection device for centrifugal film preparation

A liquid injection and film-forming technology, applied in the coating and other directions, can solve the problems of poor uniformity, strict requirements for the film-forming liquid and the danger of deflagration, and achieve the effect of reducing the shear rate and preventing it from directly falling into the film-forming area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

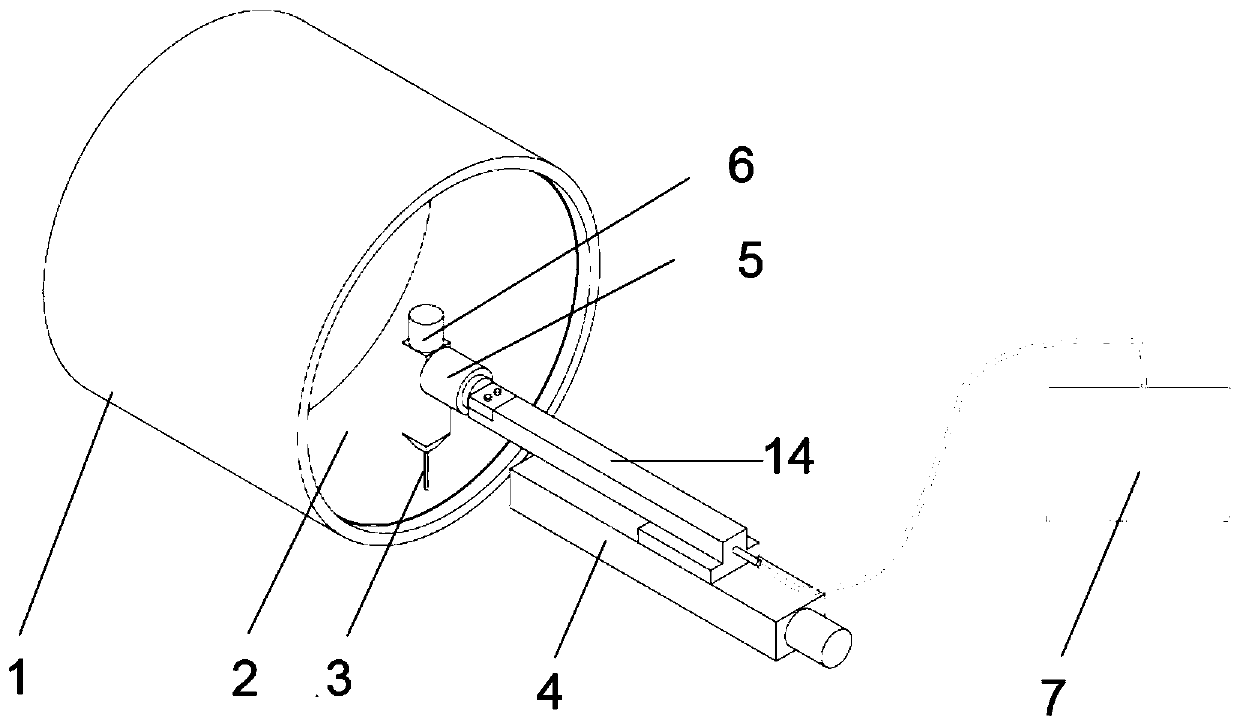

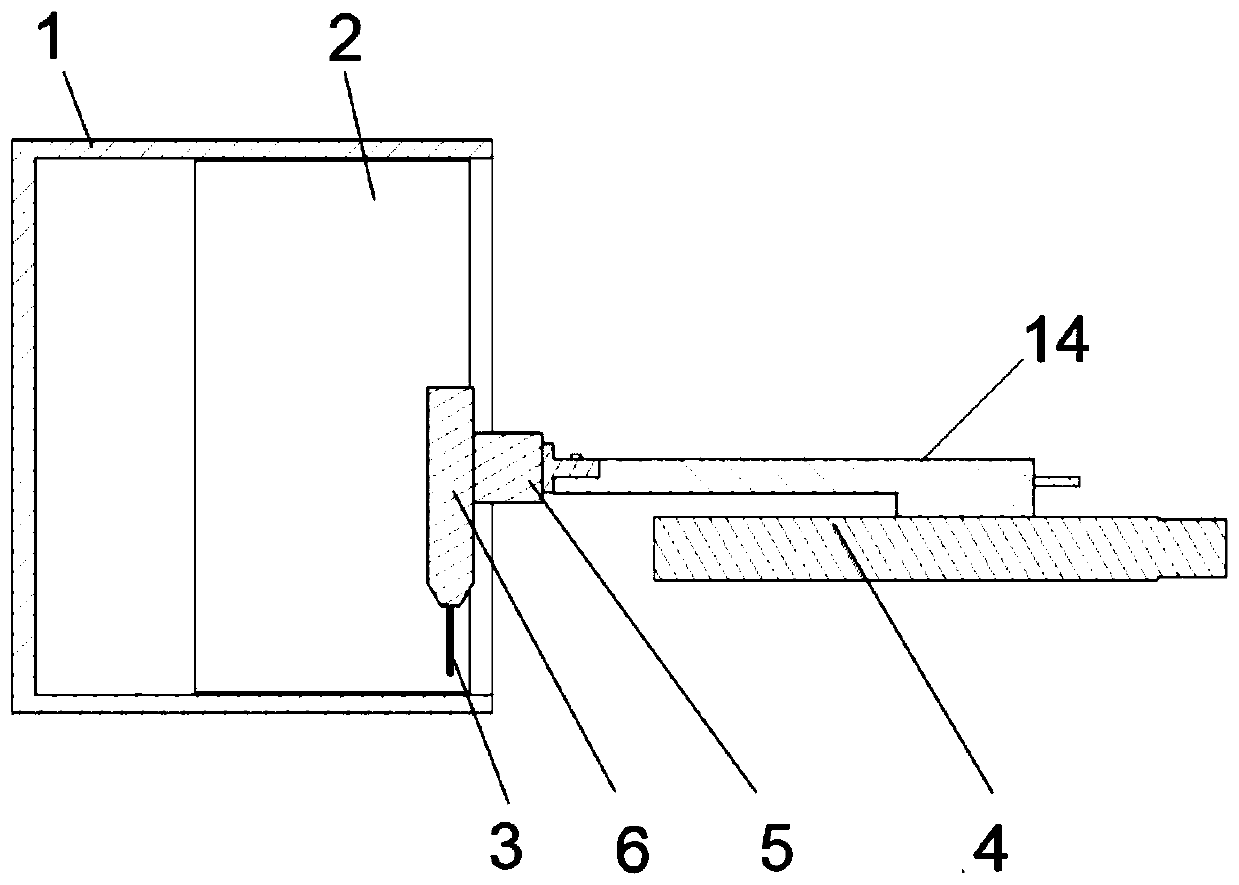

Embodiment 1

[0037] As shown in Figure 1 (a)-(b), in this embodiment, the basic structure of a simple film-forming liquid needle injection system includes: rotating drum 1, film-forming substrate 2, needle 3 (stainless steel needle), needle Moving device 4 (electric slide table) along the rotating axis of the drum, needle injection angle adjustment device 5 (reduced motor), needle telescopic device 6 (electric telescopic table), liquid booster pump 7, etc. Among them, the length of the stainless steel needle head is 50mm, the inner diameter is 300μm, and the outer diameter is 2mm; Sliding rod 14, sliding rod 14 is slidingly matched with the needle moving device 4 along the axis of rotation of the drum, and the length of sliding rod 14 is 210 mm; the needle injection angle adjustment device 5 is equipped with a deceleration stepping motor, and one end thereof is installed on the sliding rod 1 14 tail end, the other end of the needle injection angle adjustment device 5 is equipped with a nee...

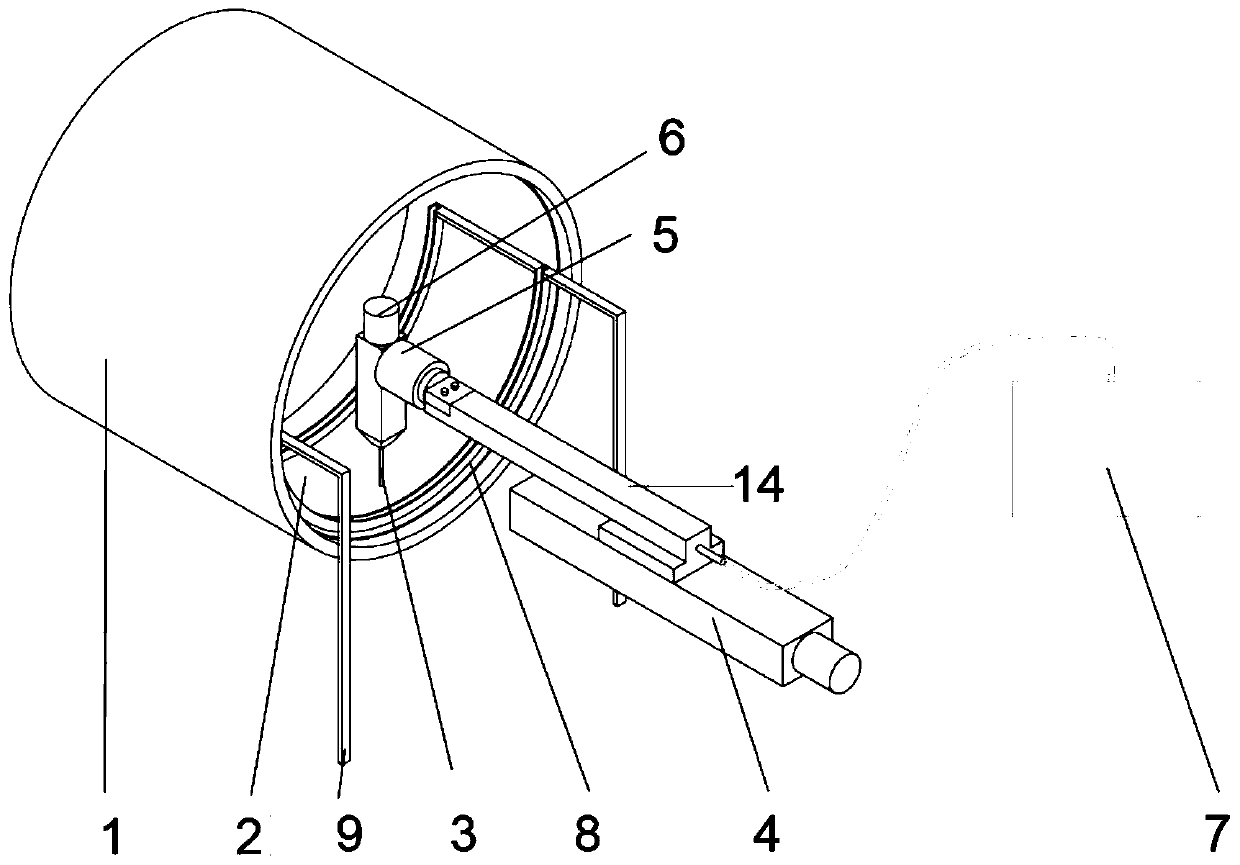

Embodiment 2

[0041] As shown in Figure 2(a)-(b), in this embodiment, a basic structure of a film-forming liquid needle injection system with a fixed residual liquid collection tank includes: a rotating drum 1, a film-forming substrate 2, a needle 3, Needle moving device 4 along the drum rotation axis, needle injection angle adjustment device 5, needle retractable device 6, liquid booster pump 7, fixed raffinate collection tank 8, fixed raffinate collection tank bracket 9, etc. Among them, the length of the stainless steel needle head is 50mm, the inner diameter is 300μm, and the outer diameter is 2mm; Sliding rod 14, sliding rod 14 is slidingly matched with the needle moving device 4 along the axis of rotation of the drum, and the length of sliding rod 14 is 210 mm; the needle injection angle adjustment device 5 is equipped with a deceleration stepping motor, and one end thereof is installed on the sliding rod 1 14 tail end, the other end of the needle injection angle adjustment device 5 i...

Embodiment 3

[0046] As shown in Figure 3(a)-(b), in this embodiment, a basic structure of a film-forming liquid needle injection system with a movable residual liquid collection tank includes: a rotating drum 1, a film-forming substrate 2, and a needle 3 , Needle head moving device 4 along the drum rotation axis, needle head injection angle adjustment device 5, needle head retractable device 6, liquid booster pump 7, movable residual liquid collection tank 10, collection tank moving device 11, etc.; wherein, the length of the stainless steel needle head is 50mm , with an inner diameter of 300 μm and an outer diameter of 2 mm; the needle head moving device 4 along the axis of rotation of the drum is a ball screw moving slide table with a width of 40 mm and a stroke of 150 mm; Rod one 14 is in sliding fit with the needle moving device 4 along the axis of rotation of the drum, and the length of the slide rod one 14 is 210mm; the needle injection angle adjustment device 5 is equipped with a dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com