Non-magnetic corrosion resisting copper alloy material

A corrosion-resistant, copper alloy technology, applied in the field of non-magnetic corrosion-resistant copper alloy materials, can solve the problems of increased internal equipment direction finding accuracy, affecting equipment direction finding accuracy, poor corrosion resistance, etc., to achieve cheap processing, The processing is simple and convenient, and the effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

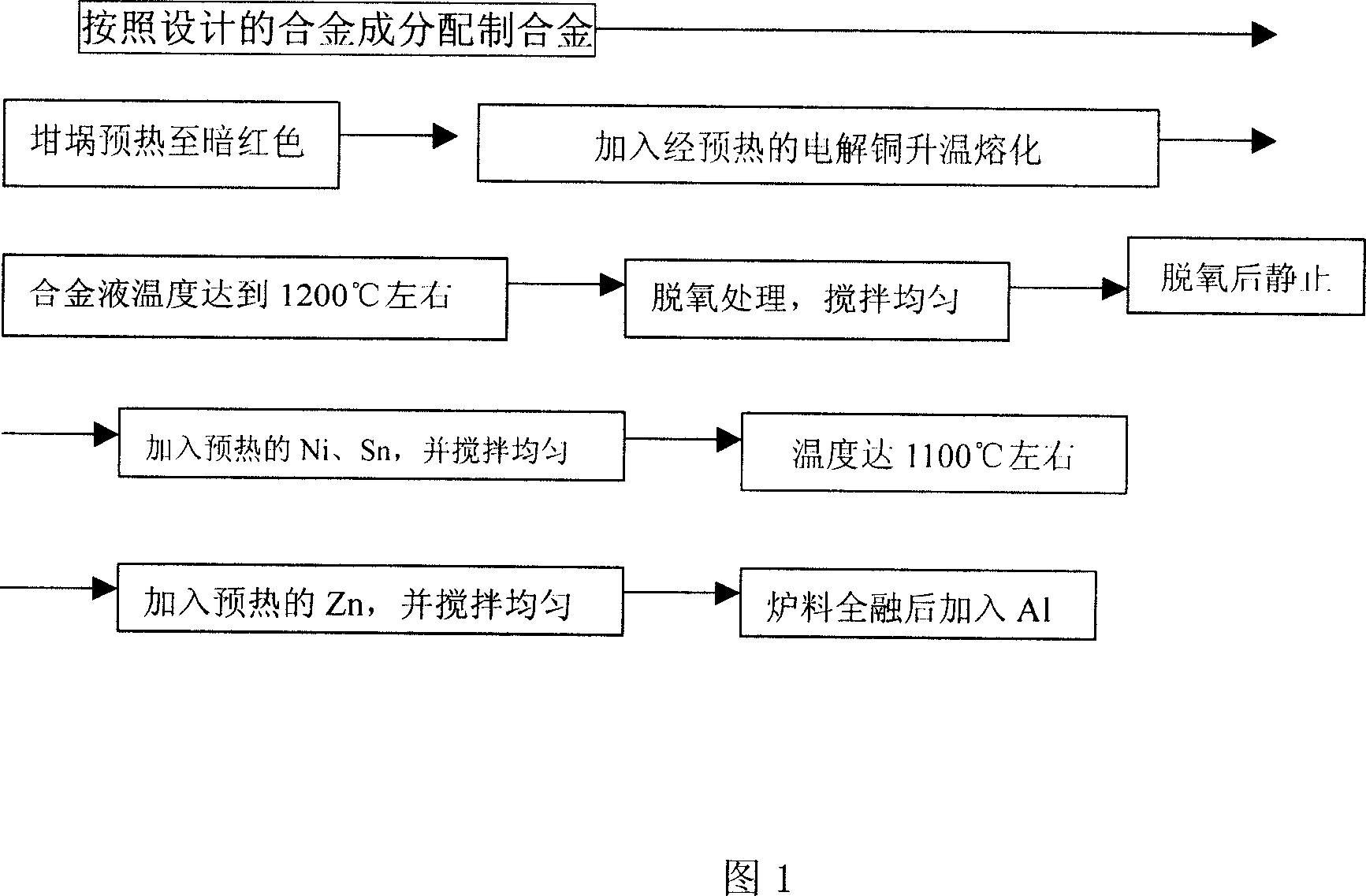

[0029] The non-magnetic corrosion-resistant copper alloy material is prepared by the following process steps, which are described in conjunction with Figure 1 (smelting process flow chart).

[0030] (1), prepare materials according to the following alloy composition content, wherein, copper raw material is to adopt electrolytic copper, Ni 0.05wt%, Al 15wt%, Zn 8wt%, Sn 1wt%, surplus is Cu;

[0031] (2), electrolytic copper, Ni, Sn, Zn are respectively preheated, and the preheating temperature is respectively 200 ℃;

[0032] (3), the crucible is preheated to dark red;

[0033] (4) Add preheated electrolytic copper into the crucible to heat up and melt, and the temperature of the molten liquid reaches 1200°C;

[0034] (5), carry out deoxidation treatment to above-mentioned molten liquid, stir evenly, stand still after deoxidation;

[0035] (6), add the preheated raw material Ni, Sn in the above molten liquid, and stir evenly, the temperature reaches 1100 ℃;

[0036] (7), add ...

Embodiment 2

[0040] Example 2 is the same as Example 1 except that the content of alloy components is different from Example 1.

[0041] The composition content of the copper alloy in Example 2 is: Ni 2wt%, Al 2wt%, Zn 0.5wt%, Sn 10wt%, and the balance is Cu.

[0042] try

Embodiment 3

[0044] Embodiment 3 is the same as Embodiment 1 except that the content of alloy components is different from that of Embodiment 1.

[0045] The composition content of the copper alloy in Example 3 is: Ni 1wt%, Al 8wt%, Zn 4wt%, Sn 5wt%, and the balance is Cu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com