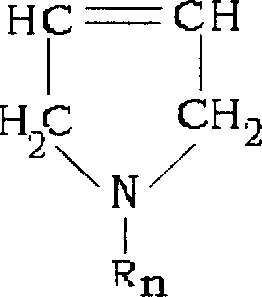

Production of maleimide resin emulsion

A maleimide and resin-like technology, which is applied in the field of polymer emulsion preparation, can solve the problems of polymerization method discussion and slow reaction speed, and achieve the effects of uniform composition and structure, stable reaction process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A. Preparation of monomer mixture

[0044] At 30°C, add 30 parts of N-phenylmaleimide, 45 parts of styrene, 25 parts of acrylonitrile, 0.35 parts of azobisisobutyronitrile, and 0.1 part of tert-dodecylmercaptan into the mixing tank, and start stirring Mixing is carried out to form a homogeneous monomer mixture (a).

[0045] B. Preparation of resin emulsion

[0046] Add 160 parts of desalted water and 3.5 parts of sodium lauryl sulfate into the reactor equipped with a stirring device at 30°C, start the stirring, emulsify for 30 minutes to heat up, and maintain the temperature of the system at 75°C, at 5 Continuously add (a) into the reactor to carry out the polymerization reaction within one hour; After the feeding is finished, the system temperature is raised to 95° C., and the polymerization reaction is carried out for another 1.0 hour, and the total solid content is measured by sampling. After passing (37.3%), the A resin emulsion (b) is formed.

[0047] 5.0% potas...

Embodiment 2

[0052] A. Preparation of monomer mixture

[0053] At 35°C, add 5 parts of N-phenylmaleimide, 65 parts of styrene, 30 parts of acrylonitrile, 0.55 parts of azobisisobutyronitrile, and 0.12 parts of tert-dodecanemercaptan into the mixing tank, and start stirring Mixing is carried out to form a homogeneous monomer mixture (a).

[0054] B. Preparation of resin emulsion

[0055] Add 150 parts of desalted water and 3.5 parts of sodium dodecylbenzenesulfonate into the reactor equipped with a stirring device at 35°C, start stirring, emulsify for 40 minutes to heat up, and maintain the temperature of the system at 60°C. Continuously (a) is joined in the reactor in 7 hours and carries out polymerization reaction; After feeding finishes, system temperature is raised to 90 ℃, and polymerization reaction is carried out again 1.0 hour, and sampling measures total solid content, after passing (38.1% ) That is, the resin emulsion (b) is formed. After the polymerization of (b) is completed,...

Embodiment 3

[0059] A. Preparation of monomer mixture

[0060] At 28°C, add 30 parts of N-phenylmaleimide, 45 parts of styrene, 25 parts of acrylonitrile, 0.45 parts of azobisisobutyronitrile, and 0.11 parts of tertiary dodecylmercaptan into the mixing tank, and start stirring Mixing is carried out to form a homogeneous monomer mixture (a).

[0061] B. Preparation of resin emulsion

[0062] Add 170 parts of desalted water, 2.3 parts of sodium lauryl sulfate, and 1.5 parts of synthetic fatty acid potassium into the reactor equipped with a stirring device at 28°C, start stirring, emulsify for 30 minutes to heat up, and maintain the temperature of the system at At 75°C, continuously add (a) into the reactor for polymerization within 5 hours; after the addition, raise the temperature of the system to 95°C, carry out the polymerization for another 1.0 hour, take a sample to measure the total solid content, and pass Afterwards (36.7%) the resin emulsion (b) is formed. After the polymerization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com