Potassium hexatitanate whisker and its prepn process

A potassium hexatitanate whisker and whisker technology, applied in the field of materials, can solve the problems of high risk and high pressure, and achieve the effect of good shape, good quality and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Raw material preparation: industrial anatase titanium dioxide (TiO 2 ), analytically pure potassium hydroxide (KOH) as raw material, wherein K 2 O:TiO 2 =2: 1 molar ratio, 2. Loading: mix the prepared materials evenly, put into a stirred reactor, add distilled water, adjust the weight percentage concentration of KOH to be 10%, then tighten and seal the reactor; 3. Reaction: Heat the reactor, and raise the temperature of the reactor at a heating rate of 3°C / min, so that the temperature rises to 320°C, while stirring at a speed of 100r / min, and keep at 320°C for 2h; 4. Product treatment: After the above After the reaction product was separated from solid and liquid by filtration, it was washed with distilled water to pH ≈ 7.2, then ultrasonically dispersed for 5 minutes, and dried in an oven at 80°C for 4 hours to obtain potassium hexatitanate whiskers.

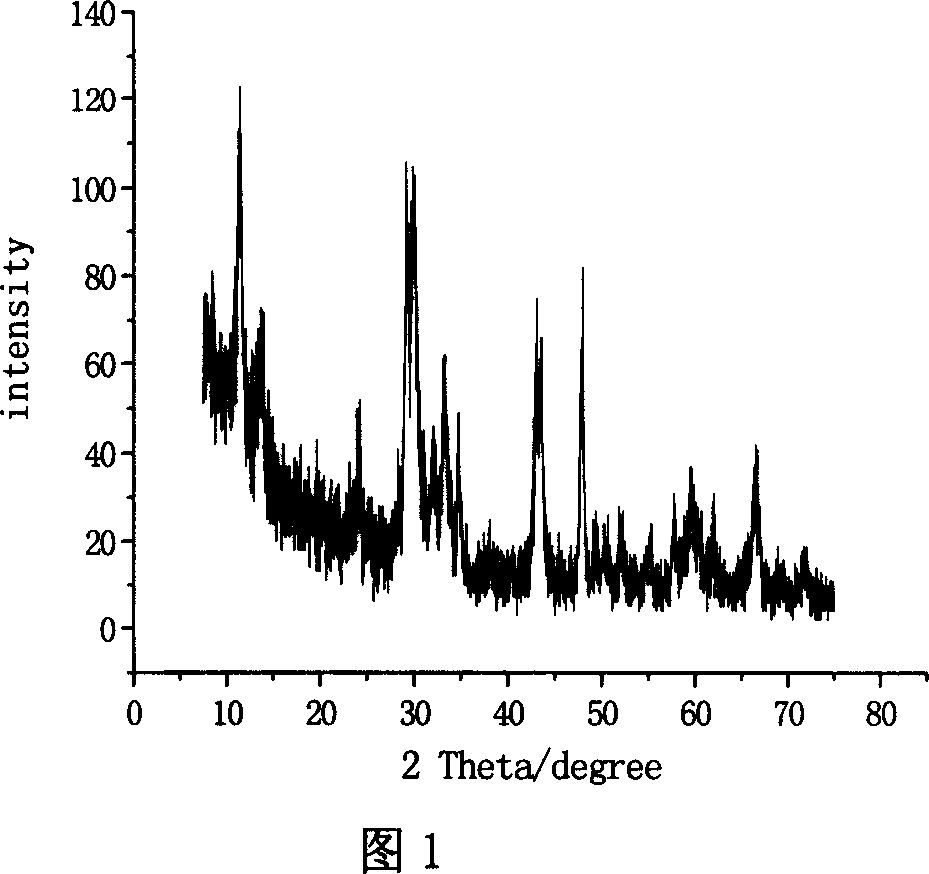

[0031] K obtained above 2 Ti 6 o 13 The whiskers have a diameter of about 200nm, a length of about 20um, an as...

Embodiment 2

[0033] 1. Raw material preparation: industrial rutile TiO 2 , Analytical pure KOH is the raw material, where K 2 O:TiO 2 =5:1 molar ratio, 2. Loading: Mix the prepared materials evenly, put them into a stirred reactor, add distilled water, adjust the weight percentage concentration of KOH to be 53%, tighten and seal the reactor; 3. Reaction : Heating the reaction kettle, and heating the reaction kettle at a heating rate of 3°C / min, so that the temperature rises to 250°C, while stirring, the rotating speed is 300r / min, and kept at 250°C for 5h; 4. Product treatment: After the above After the reaction product was separated from solid and liquid by filtration, it was washed with distilled water to pH ≈ 7.3, dispersed by ultrasound for 15 minutes, and dried in an oven at 120°C for 2 hours to obtain potassium hexatitanate whiskers.

[0034] K obtained above 2 Ti 6 o 13 The whiskers have a diameter of about 200nm, a length of about 20-30um, an aspect ratio of 100, and a yield of ...

Embodiment 3

[0036] 1. Raw material preparation: industrial anatase TiO 2 , analytically pure KOH is the raw material, where K 2 O:TiO 2 =7:1 molar ratio, 2. Loading: Mix the prepared materials evenly, put them into a stirred reactor, add distilled water, adjust the weight percentage concentration of KOH to be 13%; tighten and seal the reactor, 3. Reaction : Heating the reaction kettle, and heating the reaction kettle at a heating rate of 3°C / min, so that the temperature is 300°C, and at the same time, stirring is started, and the rotation speed is 350r / min, and the temperature is kept at 300°C for 6h; 4. Product treatment: The product obtained through the above reaction was filtered for solid-liquid separation, washed with distilled water to pH ≈ 7.5, dispersed by ultrasound for 10 minutes, and dried in an oven at 100°C for 3 hours to obtain potassium hexatitanate whiskers.

[0037] K obtained above 2 Ti 6 o 13 The whiskers have a diameter of about 500nm, a length of about 20um, an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com