Insulated conductive particles and anisotropic conductive adhesive film containing the particles

A technology of insulating conductive and conductive particles, applied in conductive materials dispersed in non-conductive inorganic materials, assembling printed circuits with electrical components, circuits, etc., can solve the problem of reducing long-term reliability of electrical connections, large manufacturing time and process parameters, Problems such as the limitation of the amount of conductive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

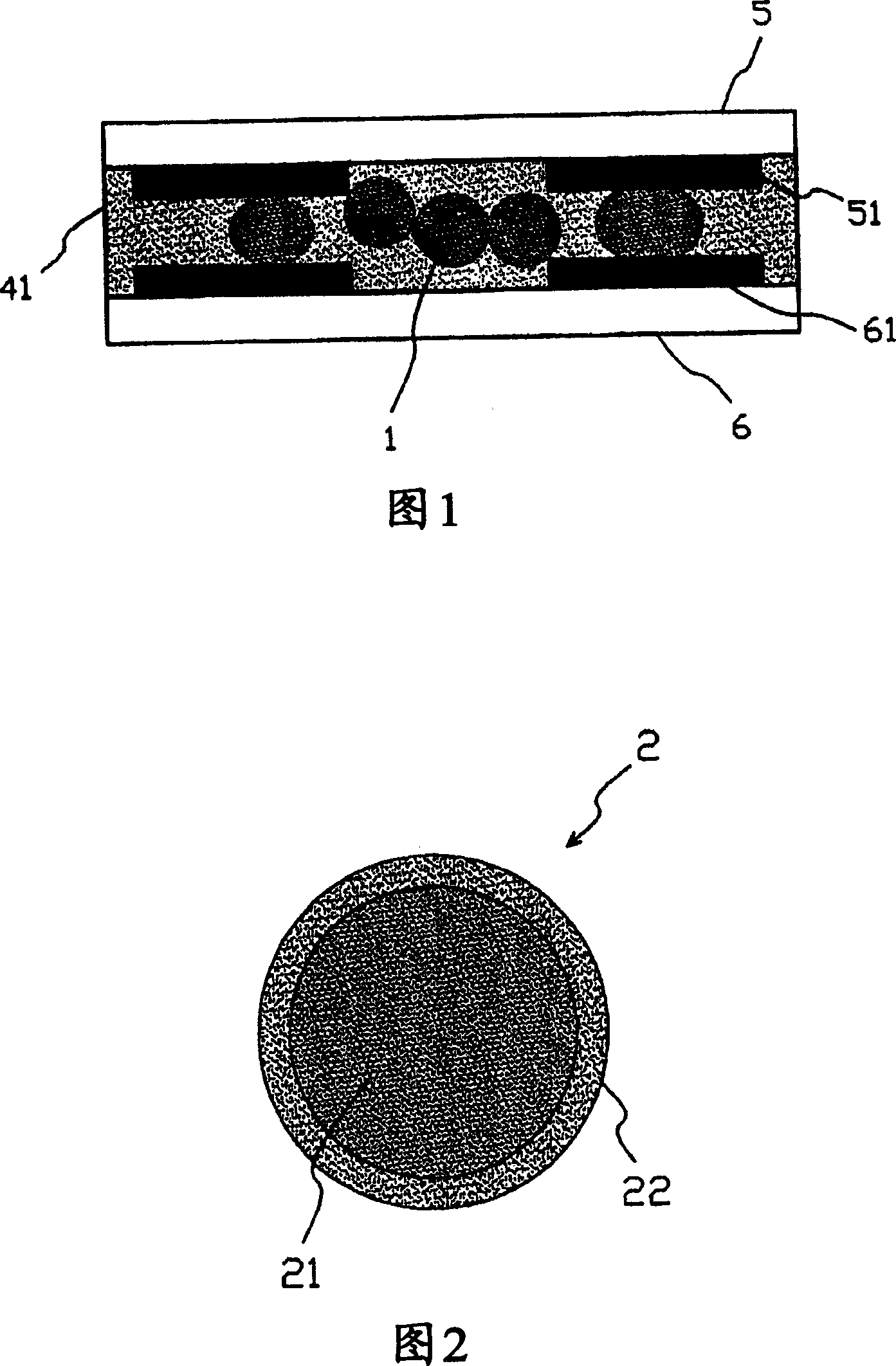

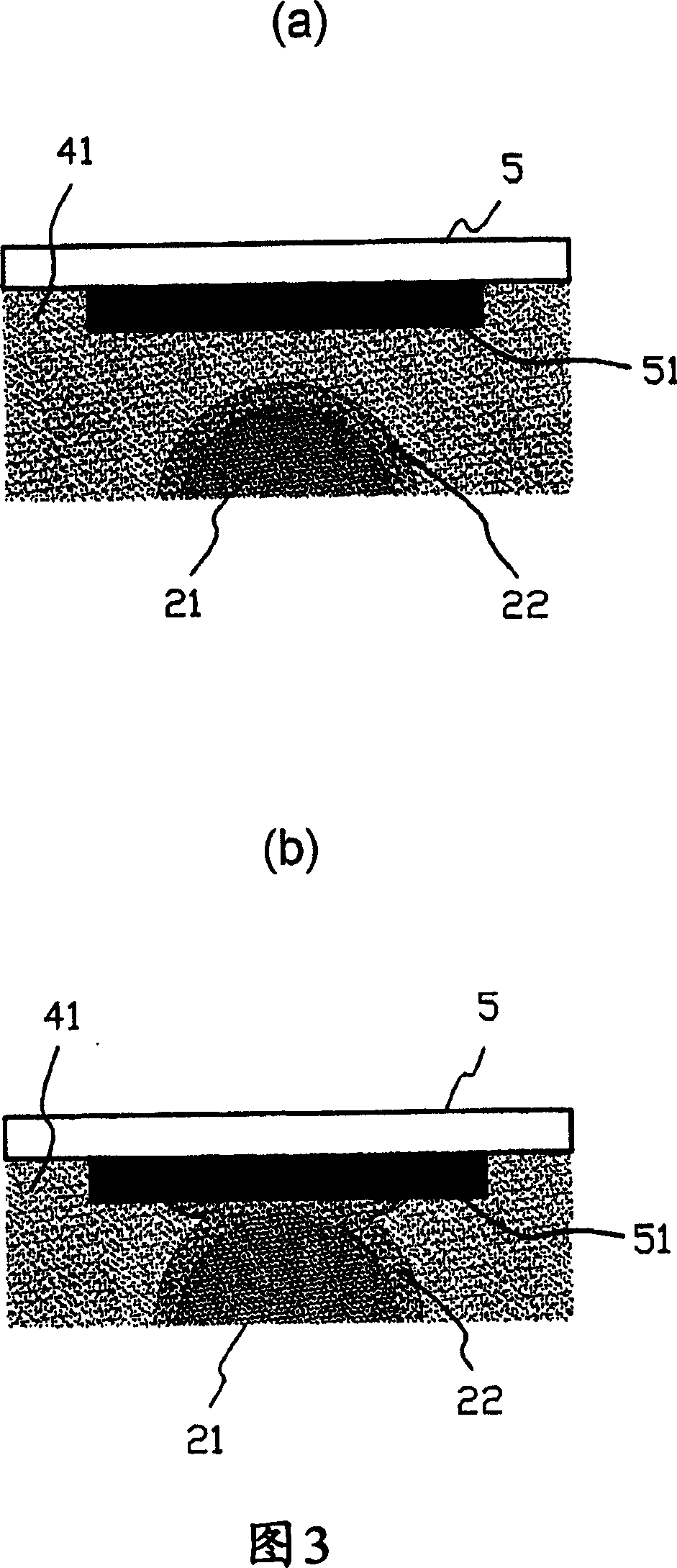

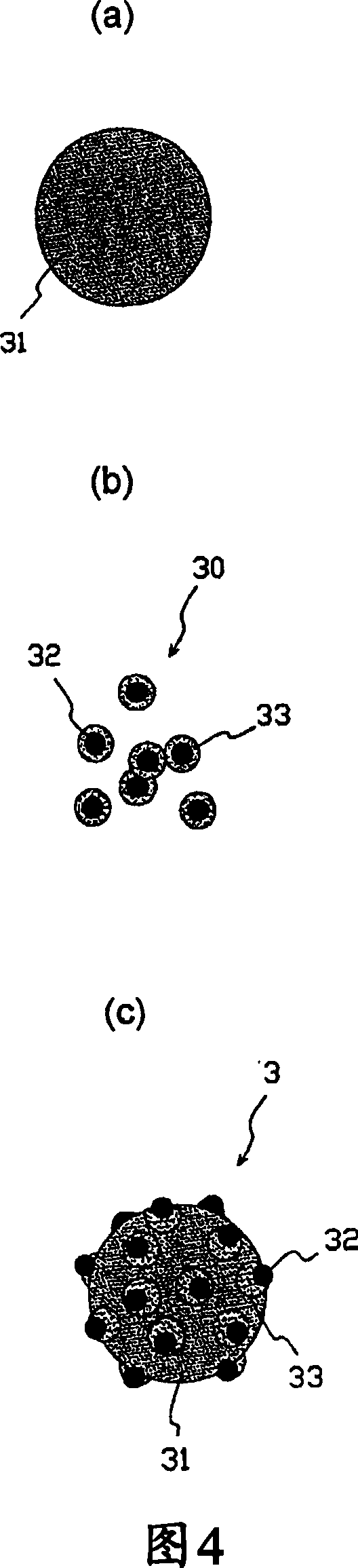

[0045] The preparation steps of each insulating fixing particle (30) include: preparing hard particles for the hard particle region (32) and preparing a polymer resin region (33) on the hard particle region (32) by seed polymerization to become a compound. The prepared insulating fixing particles (30) are fixed on the surface of the conductive particles (31) by physical / mechanical hybridization, which obtains the insulating conductive particles (3). The diameter of each insulating fixing particle (30) is 1 / 30-1 / 5 of the diameter of the conductive particle (31), and the fixing density of the insulating fixing particles fixed on the surface of the conductive particle (31) ranges from 1 to 550E. A / μm 2 . Each insulating fixing particle (30) has an aspect ratio of less than 1.5, and a coefficient of variation of less than 30%. As used herein, "aspect ratio" refers to the ratio of the largest diameter to the smallest diameter of an individual particle, and "coefficient of variat...

Embodiment 1

[0078] In Example 1, insulating conductive particles were prepared as follows.

[0079] First, mix methyl methacrylate (MMA) monomer and divinylbenzene (DVB), and mix with 1g azobisisobutyronitrile (as fat-soluble initiator), 17.9g polyvinylpyrrolidone (its molecular weight is 40,000, as a dispersion stabilizer), and 877.7 g of a solution containing methanol as a whole and ion-exchanged water (as a solvent) were stirred and then completely dissolved in the reactor. This was maintained so that the total weight of the monomers was 100 g, 30.0% by weight of MMA was applied to the DVB, and polymerization was carried out for 24 hours during stirring at 70° C. and a stirring rate of 200 rpm. The resulting polyMMA-DVD particles were separated from unreacted substances and dispersion stabilizers using a centrifugal separator, and then dried in a vacuum oven for 24 hours, which provided hard particles of 400 nm in powder form.

[0080] 20 g of the prepared polyMMA-DVD particles were d...

Embodiment 2

[0083] Example 2 was carried out in the same manner as in Example 1, except that insulating fixing particles were prepared as follows.

[0084] First, 0.125g of azobisisobutyronitrile (as a fat-soluble initiator), 8g of polyvinylpyrrolidone (its molecular weight is 40,000, as a dispersion stabilizer), and 76.375g of methanol (as a solution) and (methacryloyloxy propyl)propyltrimethoxysilane (MOPTMS) (with different weight fractions relative to styrene monomer) was added to the styrene monomer in the reactor. The total weight of the monomers was adjusted to 12.5 g, and then 30% by weight of propylmethoxysilane was added. The compound was stirred at room temperature for several hours. Water was added in an amount of 3% relative to the total weight and stirred together with the water, and then polymerization was performed at 200 rpm and 70° C. for 24 hours while stirring. This gives polystyrene-silica particles. After removing the unreacted matter and the dispersion stabilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com