Method for notably improving low-temperature conductivity of Y2O3 stable ZrO2 ceramic material

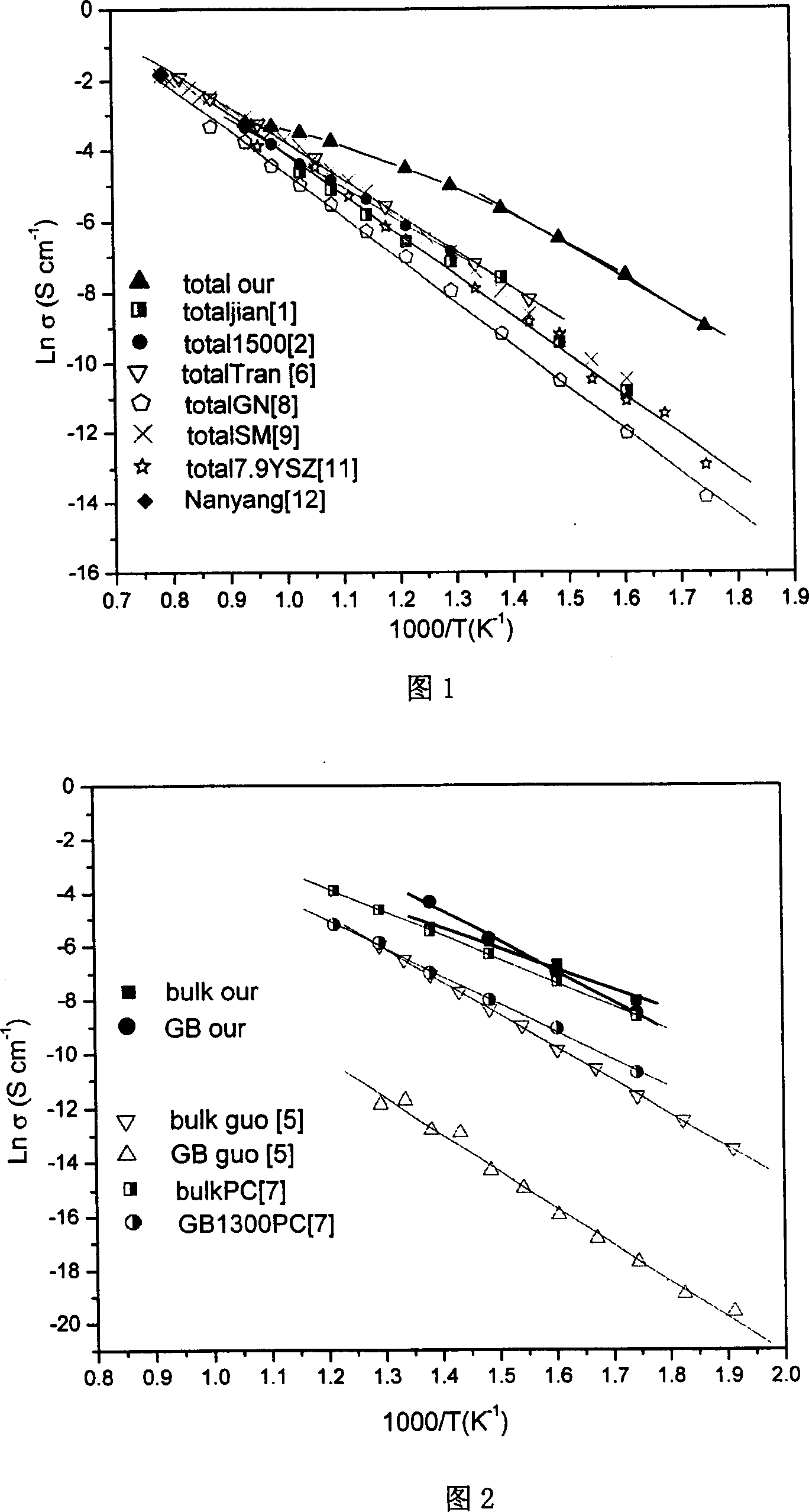

A ceramic material and conductivity technology, applied in the field of low-temperature conductivity, can solve the problems of reducing the total resistance of YSZ ceramic materials, reducing the thickness of the block, and limited resistivity, so as to achieve low cost and improve grain boundary conductivity and conductivity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A significantly higher Y 2 o 3 Stabilized ZrO 2 A method for low-temperature electrical conductivity in a ceramic material, comprising the steps of:

[0016] 1. Preparation of YSZ nanopowder:

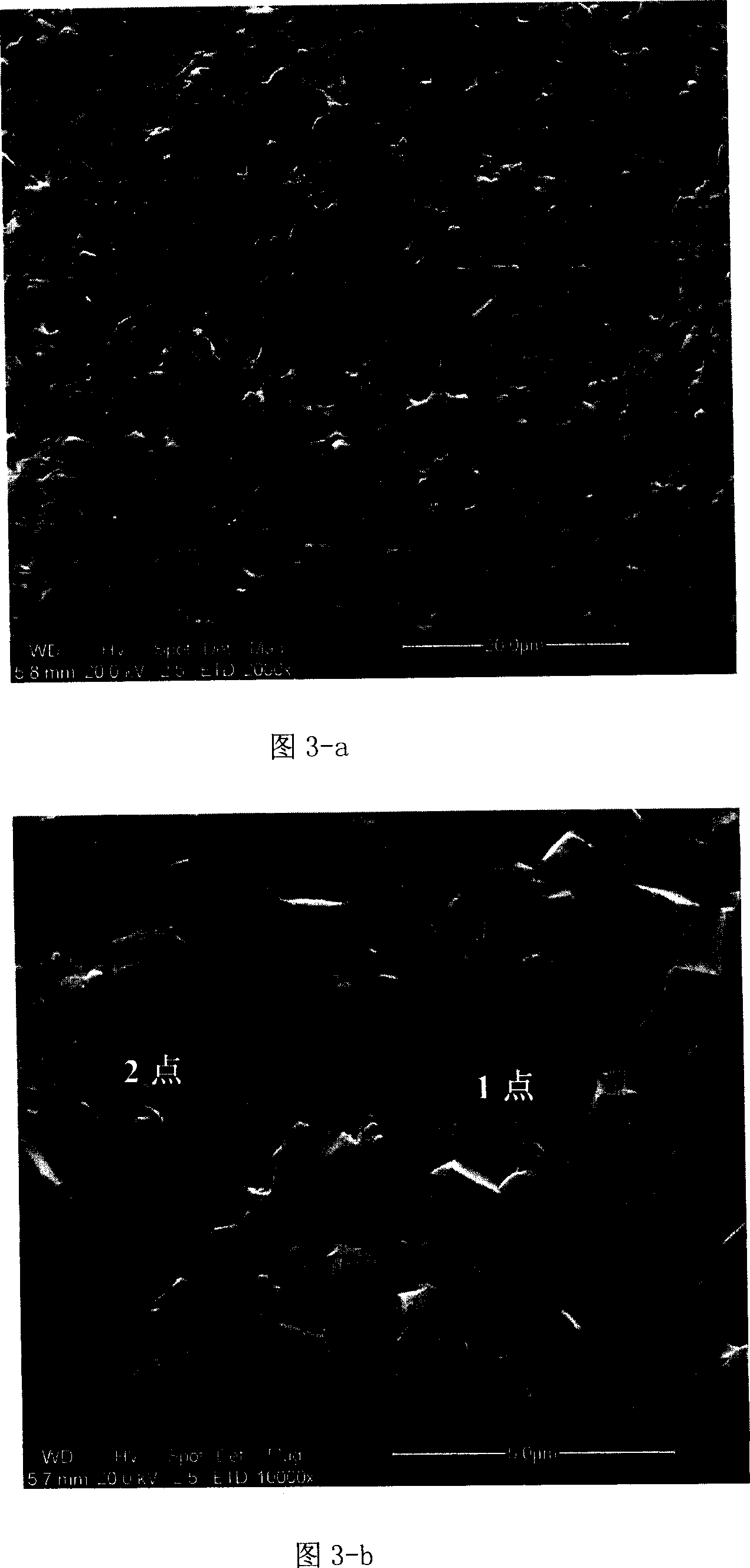

[0017] With high purity ZrOCl 2 .8H 2 O and Y (NO 3 ) as raw material, according to 92mol% ZrO 2 than 8mol% Y 2 o 3 Mix to prepare a mixed solution; drop ammonia water with a molar ratio (1:1) into the continuously stirred mixed solution, control the temperature of the mixed solution to 60°C, and the pH value to 9.5; after the reaction is completed, filter and use deionized water The precipitate was washed repeatedly to remove excess Cl - , NH 4 + Plasma; then wash the precipitate with alcohol to remove the water in the precipitate; bake the precipitate in a vacuum oven at 60°C for 15 hours to obtain the YSZ precursor; grind the precursor powder and calcinate it at 700°C for 2 hours to obtain YSZ nano powder. XRD analysis confirmed that the prepared nanopowder was cu...

Embodiment 2

[0038] A significantly higher Y 2 o 3 Stabilized ZrO 2 The method for low-temperature electrical conductivity in ceramic materials comprises the following steps: putting YSZ powder with a particle size of 10-20nm into a graphite mold with an inner diameter of 10mm, and sintering with pulse current sintering equipment (SPS-1050); The pressure is 25MPa, the heating rate is 70°C / min, the temperature is kept at 1150°C for 3 minutes, cooled with the furnace, and then annealed in the air at 1000°C for 2 hours to remove free carbon and obtain Y 2 o 3 Stabilized ZrO 2 Ceramic material, its conductivity at 300~500℃ is 1.013×10 -4 S / cm~5.065×10 -3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com