Lithium battery high-grain-boundary-conductivity perovskite solid electrolyte and preparation method thereof

A solid-state electrolyte and lithium battery technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of poor composition accuracy, low grain boundary conductivity, complex synthesis process, etc. The effect of low temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

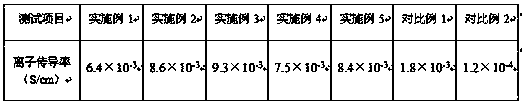

Examples

Embodiment 1

[0029] A method for preparing a perovskite solid electrolyte with high grain boundary conductance for a lithium battery, comprising the following steps:

[0030] S1, according to stoichiometric ratio Li 3x La 2 / 3-x TiO 3 Weigh LiNO 3 , La(NO 3 ) 3 , ethyl titanate (x=0.1), with LiNO 3 , La(NO 3 ) 3 , Ethyl titanate as raw material, added to the solvent, then add an appropriate amount of LiF, zirconate and lithium silicate, add auxiliary agents, to obtain a mixture; the solvent is deionized water; the zirconate is CaZrO 3 ; The auxiliary agent is LiNO 3 ; The La(NO 3 ) 3 , LiF, zirconate, lithium silicate, the mass ratio of auxiliary agent is 50:6:7:5:4;

[0031] S2. Put the mixed substance obtained in step S1 in an airtight container, stir and dissolve it under high temperature and high pressure conditions, conduct a preliminary reaction in a non-solid state, and then dry it at a temperature of 80°C, grind it, and press it into tablets to obtain Precursor sheet of ...

Embodiment 2

[0034] A method for preparing a perovskite solid electrolyte with high grain boundary conductance for a lithium battery, comprising the following steps:

[0035] S1, according to stoichiometric ratio Li 3x La 2 / 3-x TiO 3 Weigh LiNO 3 , La(NO 3 ) 3 , ethyl titanate (x=0.1), with LiNO 3 , La(NO 3 ) 3 , ethyl titanate as raw materials, added to the solvent, and then add an appropriate amount of LiF, zirconate and lithium silicate, add auxiliary agents to obtain a mixture; the solvent is absolute ethanol; the zirconate is Na 2 ZrO 3 ; The auxiliary agent is Li 2 CO 3 ; The La(NO 3 ) 3 , LiF, zirconate, silicate, the mass ratio of auxiliary agent is 60:7:6:6:4;

[0036] S2. Put the mixed substance obtained in step S1 in an airtight container, stir and dissolve it under high temperature and high pressure conditions, conduct a preliminary reaction in a non-solid state, and then dry it at a temperature of 90°C, grind it, and press it into tablets to obtain The thickness ...

Embodiment 3

[0039] A method for preparing a perovskite solid electrolyte with high grain boundary conductance for a lithium battery, comprising the following steps:

[0040] S1, according to stoichiometric ratio Li 3x La 2 / 3-x TiO 3 Weigh LiNO 3 , La(NO 3 ) 3 , ethyl titanate (x=0.12), with LiNO 3 , La(NO 3 ) 3 , ethyl titanate as raw materials, added to the solvent, and then add an appropriate amount of LiF, zirconate and lithium silicate, add auxiliary agents to obtain a mixture; the solvent is deionized water; the zirconate is Li 2 ZrO 3 ; The auxiliary agent is LiOH; The La(NO 3 ) 3 , LiF, zirconate, silicate, the mass ratio of auxiliary agent is 70:7:6:5:5;

[0041] S2. Put the mixed substance obtained in step S1 in an airtight container, stir and dissolve it under high temperature and high pressure conditions, carry out a preliminary reaction in a non-solid state, and then dry it at a temperature of 100°C, grind it, and press it into tablets to obtain The thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com