Lithium ion secondary battery

A secondary battery and lithium ion technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of accelerated battery heat release, low thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

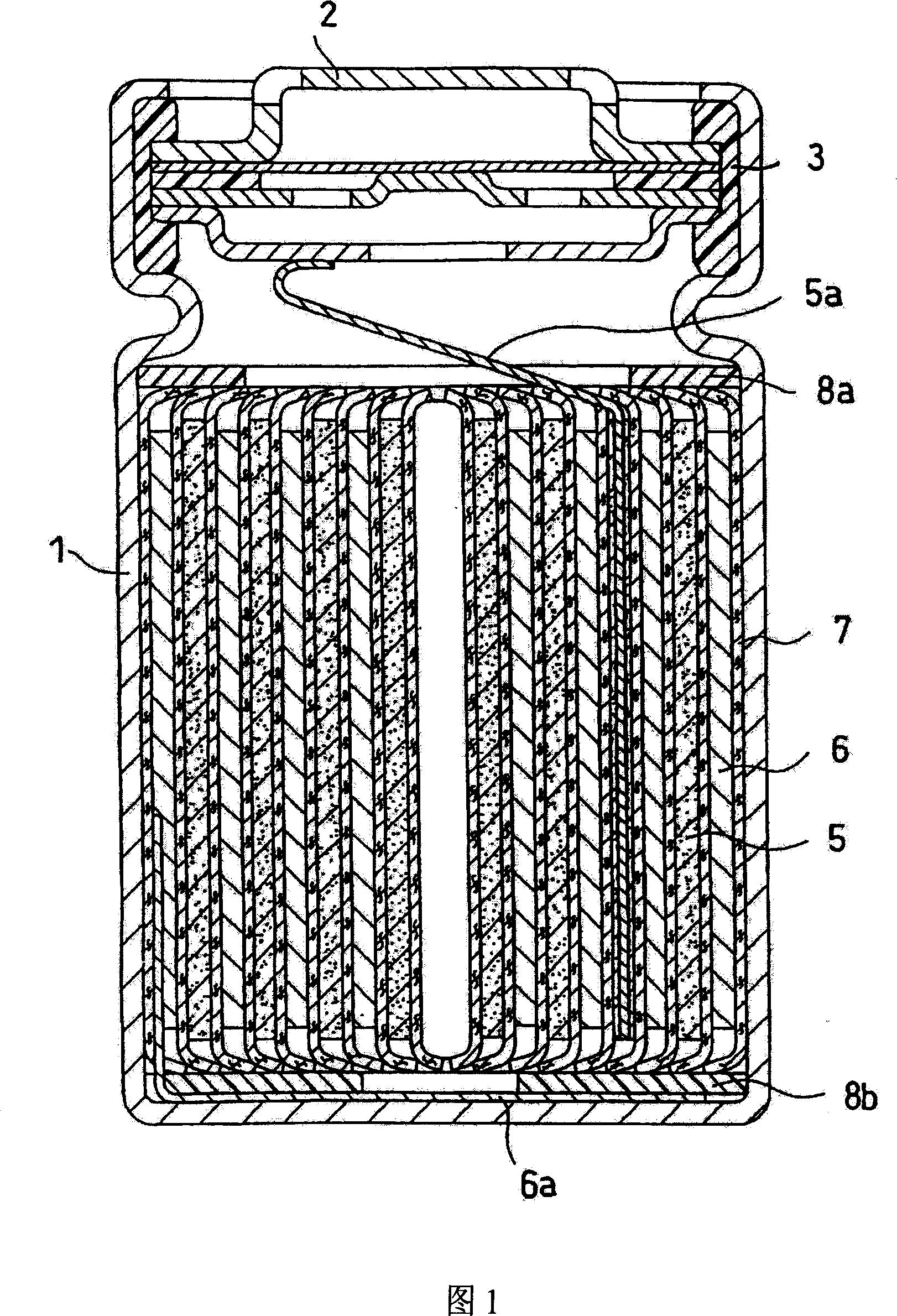

Image

Examples

Embodiment 1

[0083] (i) Preparation of positive electrode

[0084] Cobalt sulfate (CoSO 4 ) and an aqueous solution of magnesium nitrate with a concentration of 0.05mol / L are continuously added to the reactor, and sodium hydroxide is added dropwise to the reactor at the same time, so that the pH value of the water is 10 to 13, thereby synthesizing the hydroxide, namely Co 0.95 Mg 0.05 (OH) 2 , as the precursor of the active material. The precursor was placed in an oven and pre-baked at 500° C. for 12 hours in an air atmosphere to prepare a predetermined oxide.

[0085] The oxide prepared by prebaking was mixed with lithium carbonate in a molar ratio of lithium, cobalt, and magnesium of 1:0.95:0.05, and the mixture was provisionally baked at 600° C. for 10 hours, and then pulverized.

[0086] The ground baked product was then baked again at 900°C for 10 hours (final baking), and then ground and classified to obtain the formula Li(Co 0.95 Mg 0.05 )O 2 The lithium composite oxide (cath...

Embodiment 2

[0100] An aqueous solution containing cobalt sulfate at a concentration of 0.90 mol / L, magnesium nitrate at a concentration of 0.05 mol / L, and aluminum nitrate at a concentration of 0.05 mol / L was prepared. Using this aqueous solution, the hydroxide, namely Co 0.90 Mg 0.05 al 0.05 (OH) 2 , as the precursor of the active material. The precursor was placed in an oven and pre-baked at 500° C. for 12 hours in an air atmosphere to prepare a predetermined oxide.

[0101] Except that the oxide prepared by pre-baking is mixed with lithium carbonate, and the molar ratio of lithium, cobalt, magnesium and aluminum is 1:0.90:0.05:0.05, by performing the same operation as in Example 1, the following Chemical formula Li(Co 0.90 Mg 0.05 al 0.05 )O 2 The lithium composite oxide (cathode active material) shown. Then, a cylindrical battery was produced in the same manner as in Example 1 except that this positive electrode active material was used.

Embodiment 3

[0107] A cylindrical battery was produced in the same manner as in Example 1 except that a porous thin film was formed on the positive electrode material mixed layer instead of the negative electrode material mixed layer.

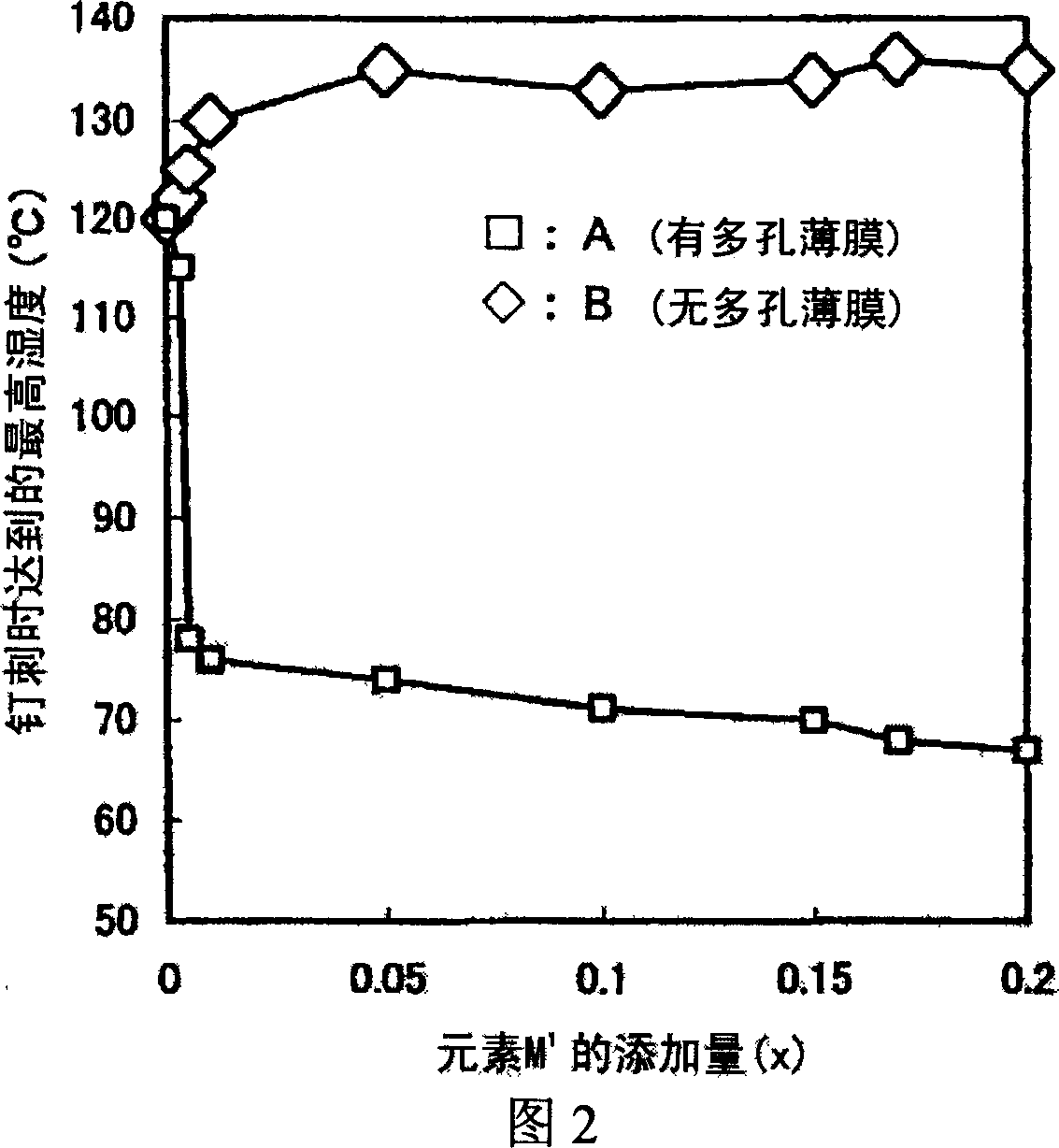

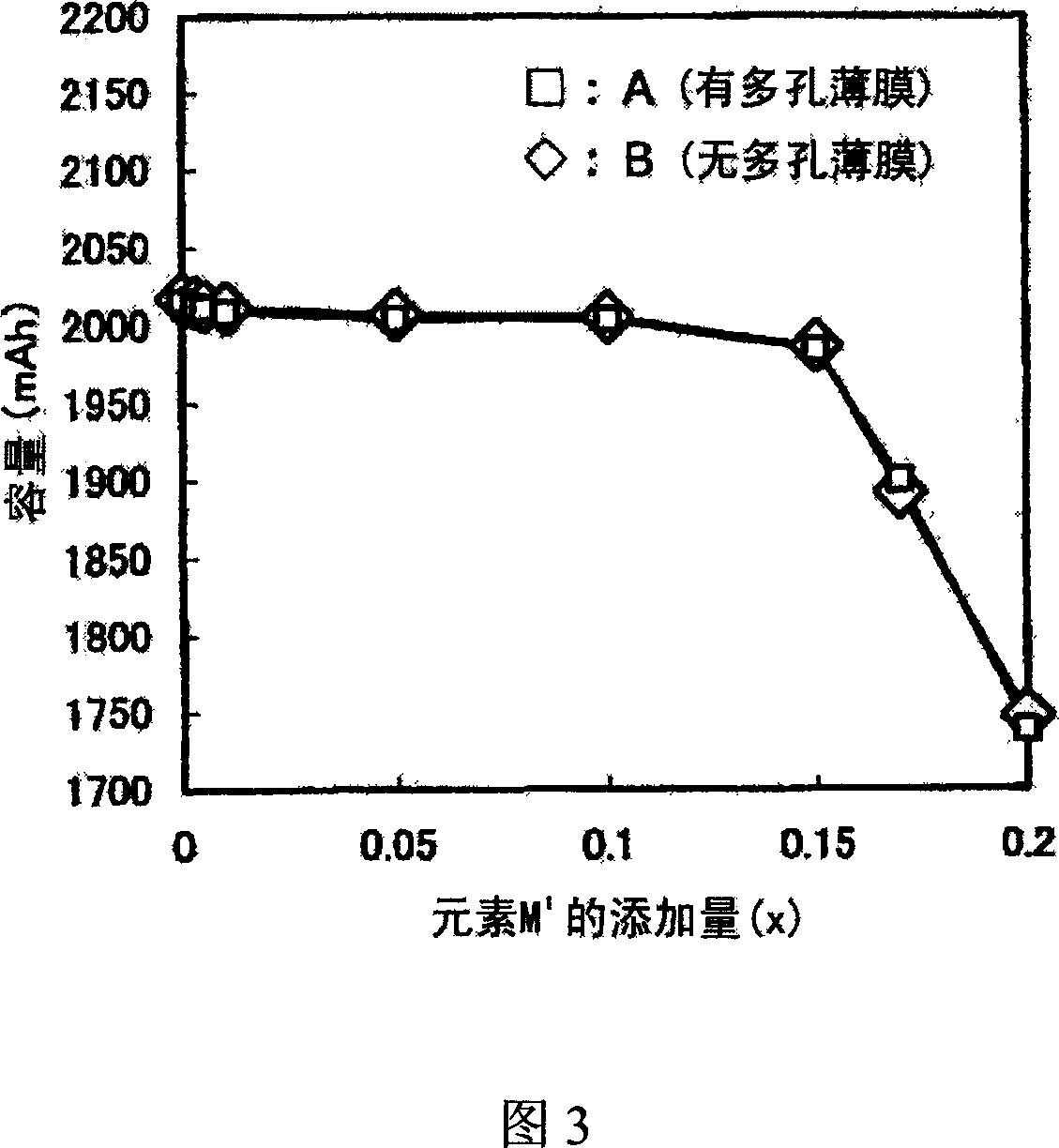

[0108] Evaluate

[0109] The battery capacity of the prepared battery was measured in the following manner. In addition, a nail penetration test and a 180-degree peel test were performed in the following manner. The results are shown in Table 1.

[0110] battery capacity

[0111] First, each battery is preliminarily charged / discharged in the following pattern. Then, each battery was stored at 45° C. for seven days.

[0112] 1) Constant current charging: 400mA (terminal voltage 4.0V)

[0113] 2) Constant current discharge: 400mA (terminal voltage 3.0V)

[0114] 3) Constant current charging: 400mA (terminal voltage 4.0V)

[0115] 4) Constant current discharge: 400mA (terminal voltage 3.0V)

[0116] 5) Constant current charging: 400mA (terminal voltage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com