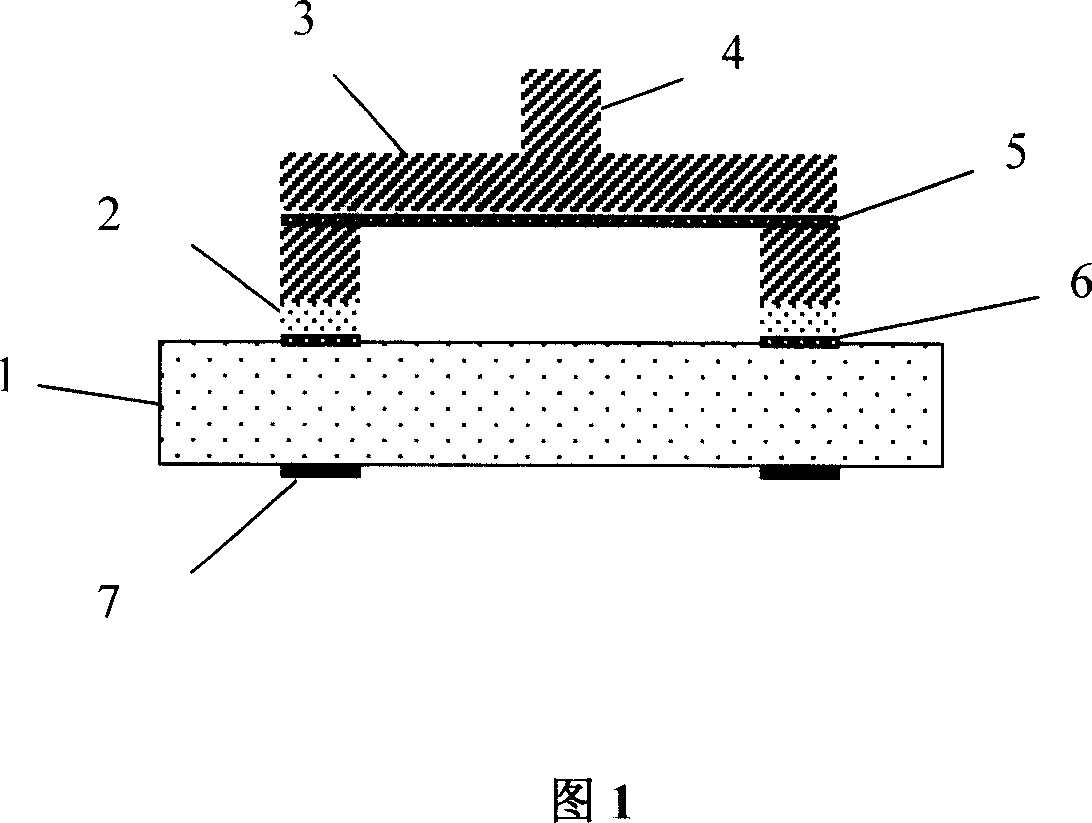

Simple-beam type microelectronic mechanical system detection card and producing method thereof

A micro-electromechanical, beam-type technology, applied in the field of integrated circuit testing, can solve problems such as unbearable, and achieve the effects of expanding adaptability, high engraving accuracy, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

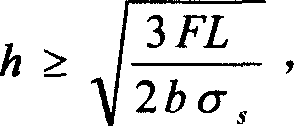

[0030] Simple supported beam structure parameters: beam thickness 15μm, probe diameter 30μm, probe height 25μm.

[0031] (1) Alignment symbol production on the back

[0032] Using a glass sheet with a thickness of 2 mm as the substrate, the substrate is first processed: ultrasonically cleaned with acetone, alcohol and deionized water, and dried in a vacuum oven at 180°C for 3 hours. Then on the back of the substrate, 100nm thick chromium is sputtered, 2μm thick AZ4620 is coated on the top of the chromium. After photolithography and development, the chromium is etched with 8% hydrochloric acid, and the photoresist is removed with acetone to obtain the chromium. Align the symbol mark on the back.

[0033] (2) Metal lead production

[0034] Wipe the front surface of the substrate without metal alignment symbols with acetone, ultrasonically clean with deionized water, and place it in a vacuum oven for drying. Sputter a 100nm bottom Cr / Cu seed layer, apply 7μm thick positive glue AZ462...

Embodiment 2

[0040] Simple supported beam structure parameters: beam thickness 10μm, probe tip diameter 30μm, probe tip height 25μm.

[0041] (1) Alignment symbol production on the back

[0042] Using a glass sheet with a thickness of 2mm as the substrate, the substrate is first processed: ultrasonically cleaned with acetone, alcohol and deionized water, and dried in a vacuum oven at 180°C for 3 hours. Then on the back of the substrate, 100nm thick chromium is sputtered, 2μm thick AZ4620 is coated on the top of the chromium. After photolithography and development, the chromium is etched with 8% hydrochloric acid, and the photoresist is removed with acetone to obtain the chromium. Align the symbol mark on the back.

[0043] (2) Metal lead production

[0044] Wipe the front surface of the substrate without metal alignment symbols with acetone, ultrasonically clean with deionized water, and place it in a vacuum oven for drying. Sputtering a 100nm bottom Cr / Cu seed layer, coating 7μm thick positiv...

Embodiment 3

[0050] Simple supported beam structure parameters: beam thickness 15μm, probe tip diameter 10μm, probe tip height 50μm.

[0051] (1) Alignment symbol production on the back

[0052] Using a glass sheet with a thickness of 2mm as the substrate, the substrate is first processed: ultrasonically cleaned with acetone, alcohol and deionized water, and dried in a vacuum oven at 180°C for 3 hours. Then on the back of the substrate, 100nm thick chromium is sputtered, 2μm thick AZ4620 is coated on the top of the chromium. After photolithography and development, the chromium is etched with 8% hydrochloric acid, and the photoresist is removed with acetone to obtain the chromium. Align the symbol mark on the back.

[0053] (2) Metal lead production

[0054] Wipe the front surface of the substrate without metal alignment symbols with acetone, ultrasonically clean with deionized water, and place it in a vacuum oven for drying. Sputter a 100nm bottom Cr / Cu seed layer, apply 7μm thick positive glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com