Method and apparatus for growing three-dimensional photon crystal film by pressure-reducing self-assembling

A photonic crystal and self-assembly technology, which is applied in crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of wide application range and increased crystal growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、235

[0036] Example 1. Preparation of 235nm three-dimensional polystyrene photonic crystal film

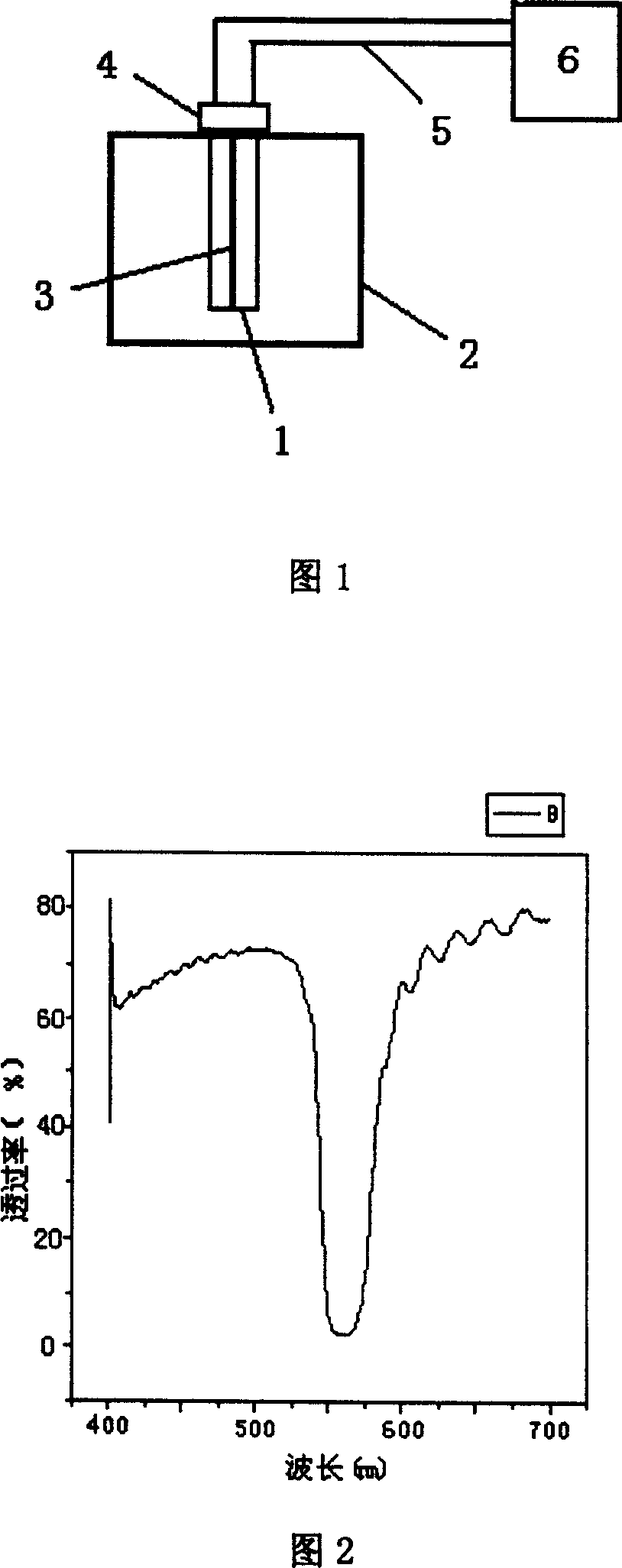

[0037] The preparation of the photonic crystal film is carried out on the device for self-assembled growth of the three-dimensional photonic crystal film provided by the present invention. The device is shown in Figure 1, including: a growth deposition bottle 1, a constant temperature device 2 installed outside, and a glass slide 3 fixed in the growth deposition bottle 1, wherein the growth deposition bottle is a sealed , The deposition bottle connected with the vacuum pumping system 6 through the vacuum pumping pipe joint 4 and the pumping pipe 5. The constant temperature device can be various conventional constant temperature heating devices.

[0038] On the above device, using the method of combining constant temperature and pressure reduction provided by the present invention to self-assemble and grow a 235nm three-dimensional polystyrene colloidal photonic crystal, the specific steps ...

Embodiment 2~9

[0046] Examples 2-9. Preparation of a series of polystyrene three-dimensional photonic crystal films with different particle diameters

[0047] According to the method in Example 1, a series of polystyrene three-dimensional photonic crystal films with different particle diameters were prepared, and the growth temperature and pressure are as listed in Table 1.

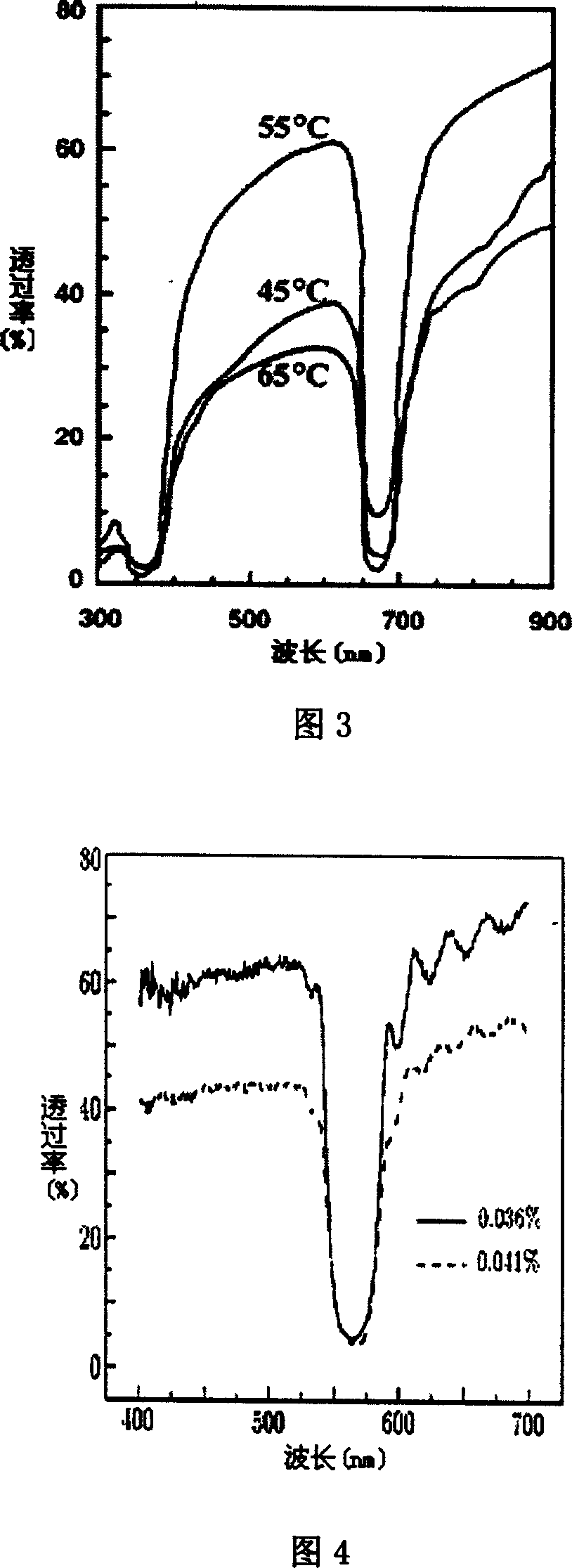

[0048] The transmittance spectrum of the series of polystyrene photonic crystal films along the direction of the crystal (111) was measured. The transmittance in the band gap and conduction band and the maximum slope of the band edge are listed in Table 1.

[0049] Table 1. Polystyrene three-dimensional photonic crystal films with different particle sizes and their optical properties

[0050]

Embodiment 10~13

[0051] Examples 10-13. Preparation of a series of silicon dioxide three-dimensional photonic crystal films with different particle diameters

[0052] According to the method in Example 1, using a mixed solution of ethanol and water of silica, the volume ratio of ethanol and water is 1:9, and a series of three-dimensional silica photonic crystal films with different particle diameters are prepared. The growth parameters are shown in the table. 2 listed.

[0053] The transmittance spectrum of incident light along the crystal (111) direction of this series of silicon dioxide photonic crystal films was measured. The transmittance in the band gap and conduction band and the maximum slope of the band edge are listed in Table 2.

[0054] Table 2. Silica three-dimensional photonic crystal films with different particle sizes and their optical properties

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com