Method of fusion spinning fire resistant special type elastic spandex fiber and producing device thereof

A technology of spandex fiber and high temperature resistance, which is applied in the field of melt-spun spandex spinning, which can solve the problems of high cost, environmental pollution, high energy consumption, etc., and achieve low production cost, improved uniformity, elongation and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

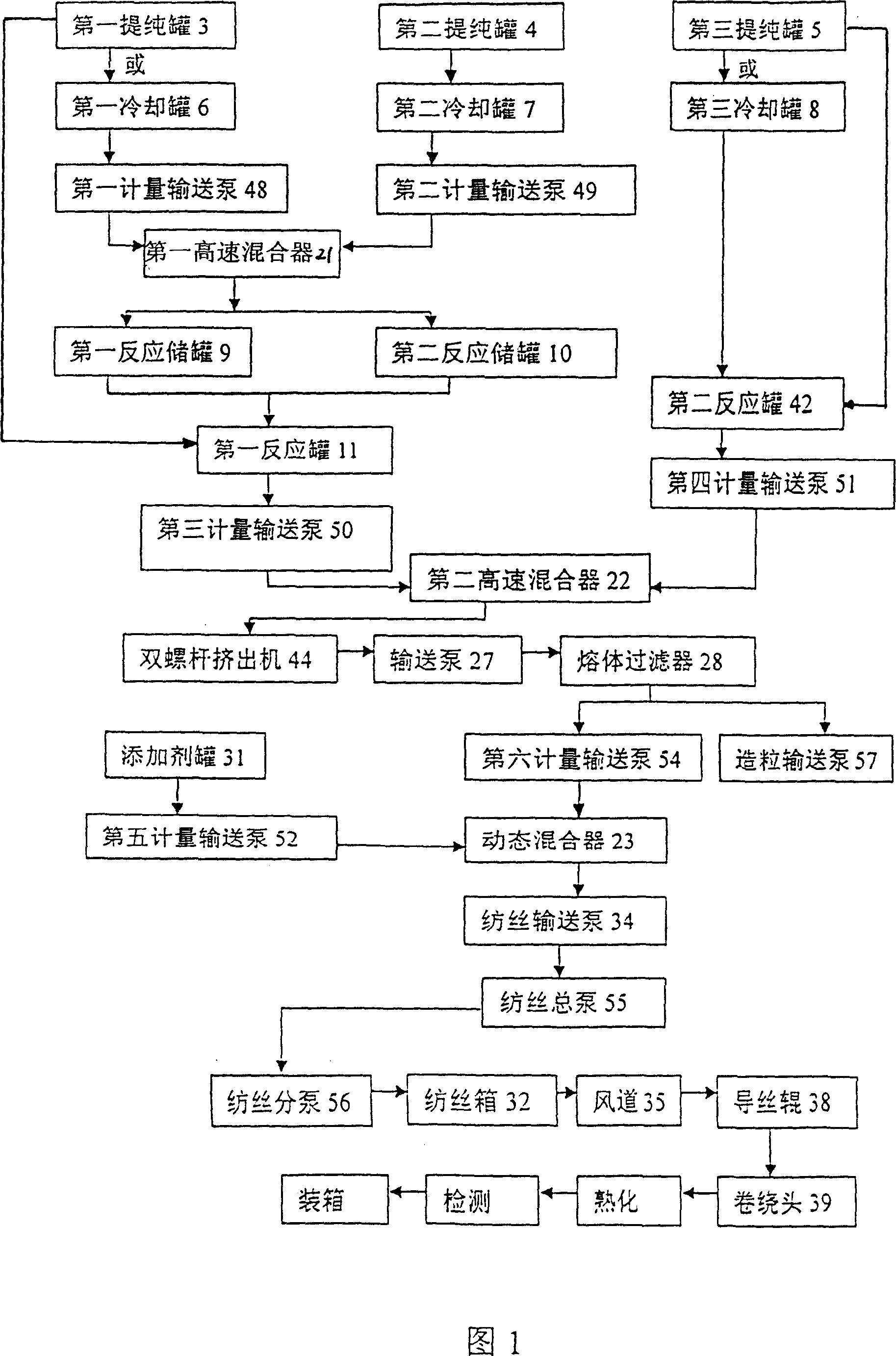

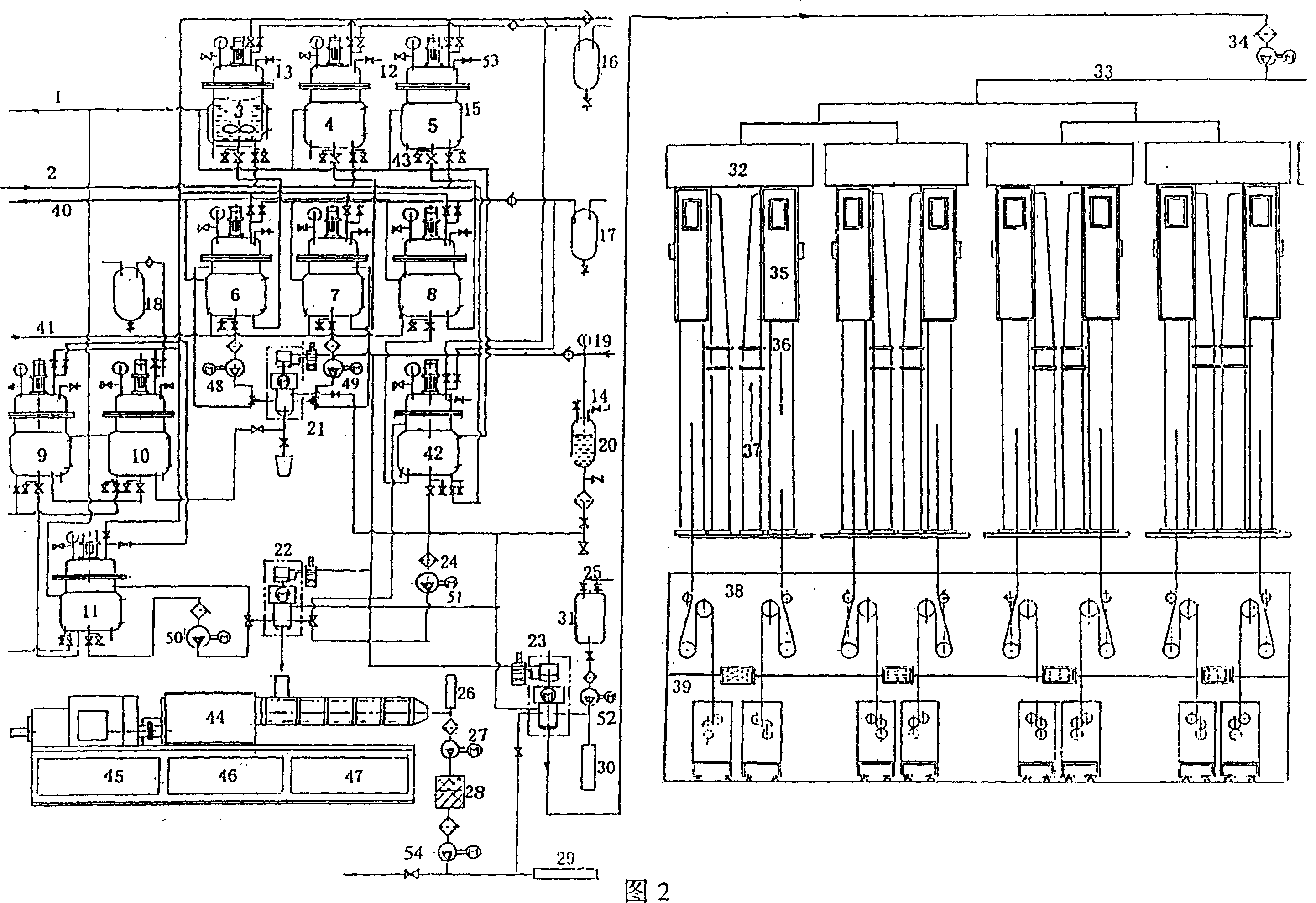

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, divide two groups, every group mix raw material 100Kg, get polyester polyol (model PBA-44) 62Kg, 75Kg by proportioning, isocyanate (model MDI) 30Kg, 20Kg, butanediol (model BDO-1, 4 ) 8Kg, 5Kg.

[0026] Negative pressure feeding: evacuate to minus 1 kg pressure, add polyester polyol and butanediol into the first purification tank 3 through the first feeding valve 13, and add isocyanate into the third purification tank 5 through the fourth feeding valve 53;

[0027] Heat the heat conduction oil to heat the raw material in the first purification tank 3 to 90°C, and purify in vacuum for 0.5 hours; heat the raw material in the third purification tank 5 to 70°C; purify in vacuum for 0.5 hour, and add 1 kg of pressure after the purification is completed;

[0028] Metering, mixing, and reaction: the raw materials in the first purification tank 3 are heated and pressurized and sent directly to the first reaction tank 11, and the raw materials in the third ...

Embodiment 2

[0031] Embodiment 2, divide two groups, every group mix raw material 100Kg, get polyester polyol (model PBA-44) 62Kg, 75Kg by proportioning, isocyanate (model MDI) 30Kg, 20Kg, butanediol (model BDO-1, 4 ) 8Kg, 5Kg; the first group plus polyether polyol (model PTMG) 8Kg, the second group plus polyether polyol (model PTMG) 16Kg;

[0032] Negative pressure feeding: evacuate to a pressure of minus 1 kg, feed polyester polyol and butanediol into the first purification tank 3 and the second purification tank 4 through the first feeding valve 13 and the second feeding valve 12 respectively, and the isocyanate passes through The fourth feeding valve 53 is added in the third purification tank 5, and the polyether polyol is added into the first purification tank through the first feeding valve;

[0033] Heat the heat conduction oil, heat the first purification tank 3 and the second purification tank 4 to 100°C, and purify in vacuum for 1 hour; heat the third purification tank 5 to...

Embodiment 3

[0037] Embodiment 3, divide two groups, every group mix raw material 100Kg, get polyester polyol (model PBA-44) 62Kg, 75Kg by proportioning, isocyanate (model MDI) 30Kg, 20Kg, butanediol (model BDO-1, 4 ) 8Kg, 5Kg; the first group plus polycaprolactone polyol (model PCL) 8Kg, the second group plus polycaprolactone polyol (model PCL) 25Kg;

[0038] Negative pressure feeding: evacuate to minus 1 kg pressure, add polyester polyol into the first purification tank 3 through the first feeding valve 13, add butanediol into the second purification tank 4 through the second feeding valve 12, and add isocyanate through the The fourth feeding valve 53 is added in the third purification tank 5, and polycaprolactone polyol is added into the first purification tank through the first feeding valve 13;

[0039] Heat the heat conduction oil, heat the first purification tank 3 and the second purification tank 4 to 100°C, and purify in vacuum for 1 hour; heat the third purification tank 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com