Electric cable for coal mining machine

A coal mining machine and cable technology, which is applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of easy fracture and scrapping, affecting data transmission, and the control wire core cannot output electromagnetic signals normally, so as to avoid fracture phenomenon and resist bending The effect of improving the ability and tensile strength and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

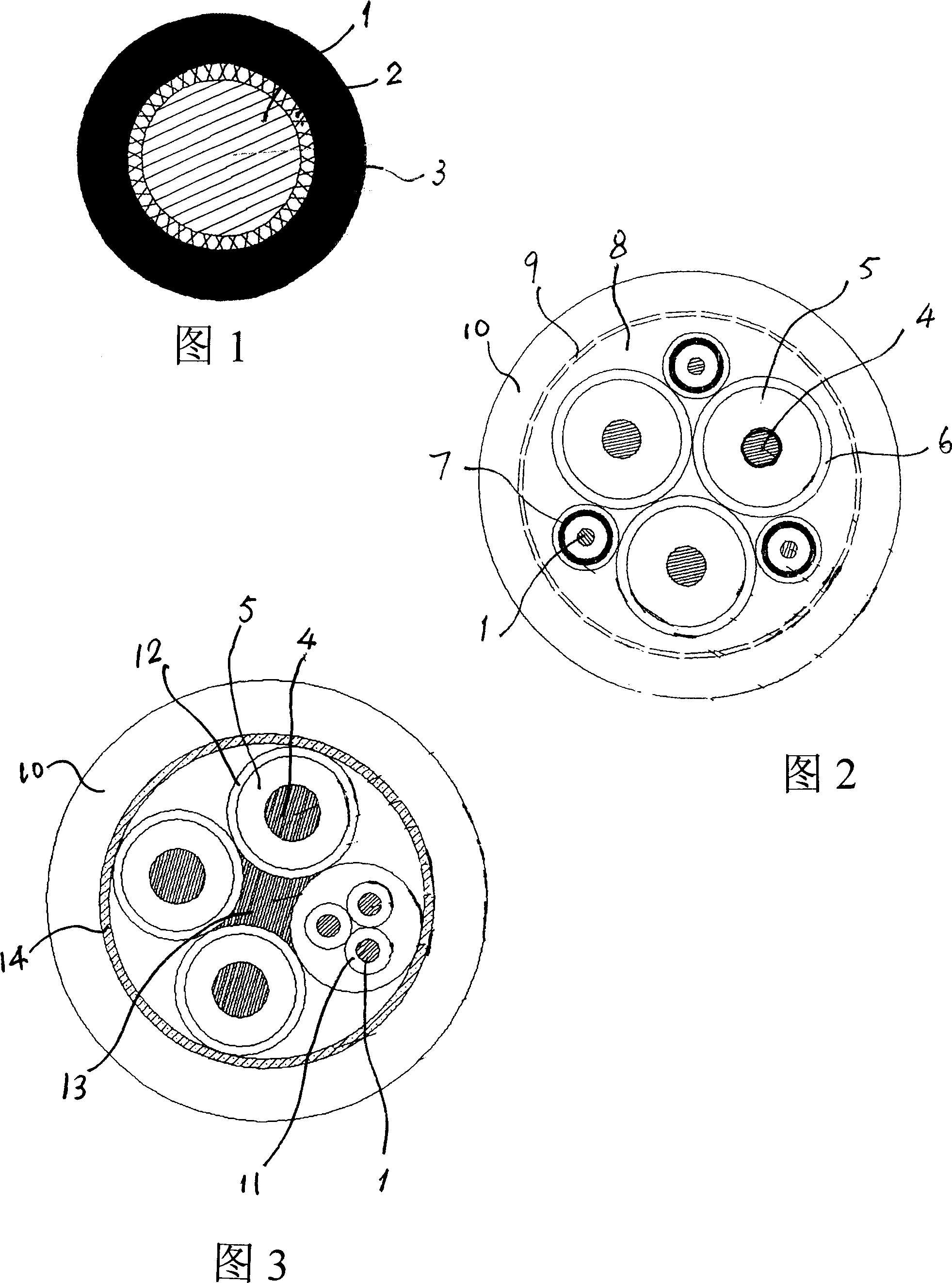

[0018] What Fig. 2 shows is the said coal mining machine cable of embodiment 1 of the present invention, the cross-sectional structure schematic diagram of the MCPJR-0.66 / 1.14 type coal mining machine shielding monitoring reinforced soft cable produced by Qingdao Hanlan Group Co., Ltd., the coal mining machine The rated voltage of the machine is 0.66 / 1.14kV. The copper conductive wire core 4 is composed of multiple strands of copper wire, and the diameter of each strand of copper wire is 0.5mm. The control wire core 1 is composed of multiple strands of copper wire, and the diameter of each strand of copper wire is The diameter is 0.25mm, the outer layer is a tightly braided layer of high-carbon steel wire, and an insulating layer of ethylene-propylene rubber is extruded outside. The core 4 of the copper conductive wire has an insulating layer 5, which is made of ethylene-propylene rubber, and the thickness is 2.0mm, outside the insulating layer 5 of the copper conductive core 4...

Embodiment 2

[0020] What Fig. 3 shows is the said coal shearer cable of embodiment 2 of the present invention, the cross-sectional structure schematic diagram of the MCPT-1.9 / 3.3 type coal shearer metal shield flexible cable that Qingdao Hanlan Group Co., Ltd. produces, and this coal shearer is rated Voltage 1.9 / 3.3kV, copper conductive wire core 4 is composed of multiple strands of copper wire, the diameter of each copper wire is 0.5mm, copper conductive wire core 4 has an insulating layer 5, and the insulating layer 5 is made of ethylene-propylene rubber The thickness is 3.0mm. The control wire core 1 is composed of multiple strands of copper wires. The diameter of each strand of copper wire is 0.25mm. , the outer insulating layer of the control wire core 1 is made of ethylene-propylene rubber with a thickness of 1.5mm, the outer insulating layer 5 of the copper conductive wire core 4 has a metal braided shielding layer 12, and the metal braided shielding layer 12 is made of tinned copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com