Surface treating method and film pattern forming method

A patterning and liquefaction processing technology, applied in conductive pattern formation, post-processing of printing, loop antenna, etc., can solve the problems of difficulty in obtaining lyophobicity, film pattern formation obstacles, etc. short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

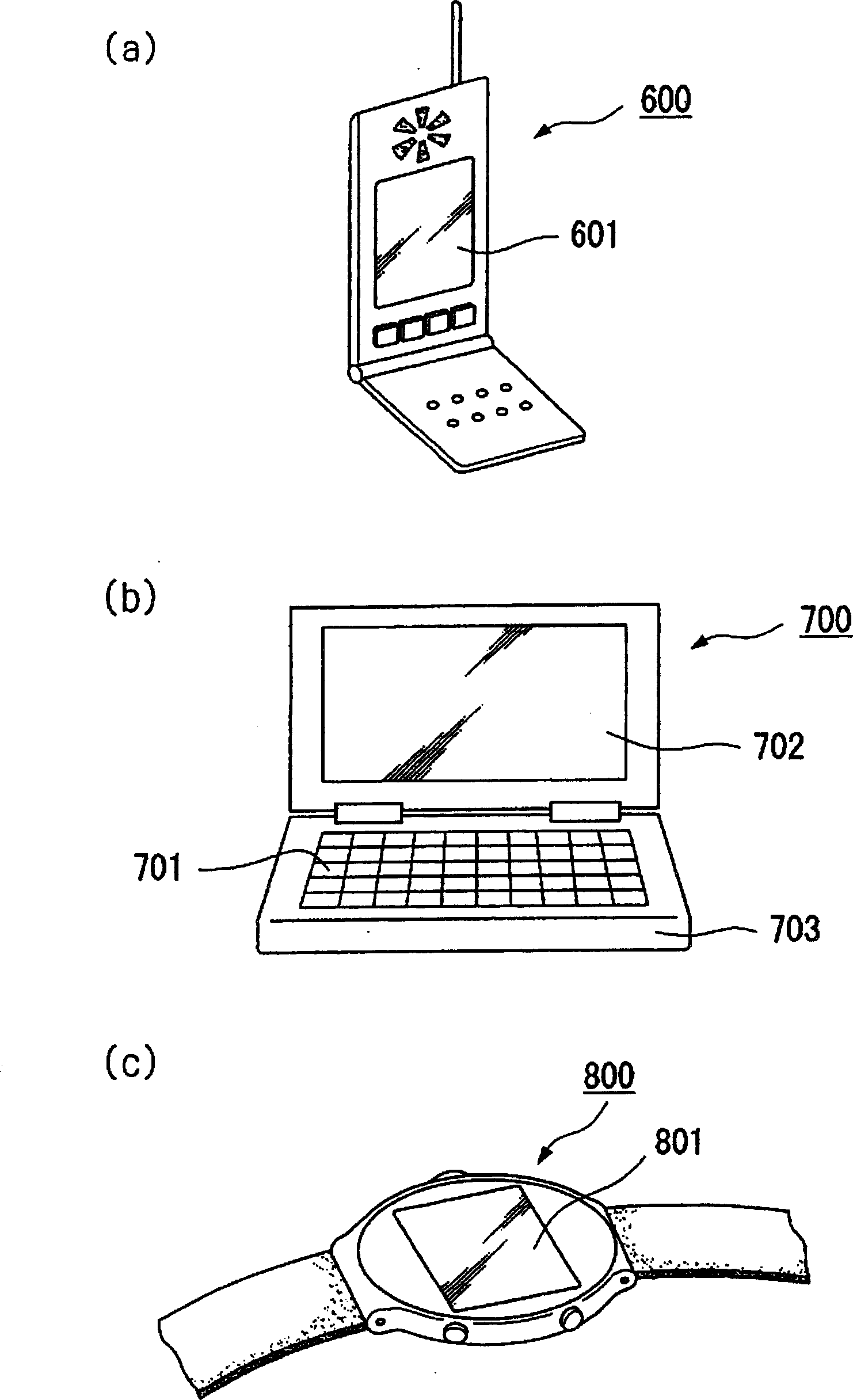

Image

Examples

Embodiment approach 1

[0058] As Embodiment 1, the surface treatment method of this invention is demonstrated. The surface treatment in this embodiment is composed of a lyophobic treatment process and a lyophilic treatment process. Each process is described below.

[0059] (lyophobic treatment process)

[0060] One of the lyophobic treatment methods includes a method of forming a self-organized film composed of an organic molecular film or the like on the surface of the substrate.

[0061] One end of the organic molecular film used to treat the substrate surface has a functional group that can be combined with the substrate, and the other end has a functional group that can change the surface property of the substrate to lyophobicity (controlling the energy of the surface), and has a straight chain connecting these functional groups. Carbon or partially branched carbon chains are combined on the substrate to self-organize to form a molecular film, such as a monomolecular film.

[0062] A self-org...

Embodiment approach 2

[0078] As Embodiment 2, the wiring formation method which is an example of the film pattern formation method of this invention is demonstrated. The wiring forming method of this embodiment is composed of a surface treatment process, a discharge process, and a heat treatment / light treatment process. Each process will be described below.

[0079] (surface treatment process)

[0080] Various materials such as silicon wafers, quartz glass, glass, plastic films, and metal plates can be used as substrates on which wirings made of conductive films are to be formed.

[0081] In addition, materials obtained by forming a semiconductor film, a metal film, a dielectric film, an organic film, etc. as an underlayer on the surface of a substrate made of various materials can also be used as a substrate on which conductive film wiring is to be formed.

[0082] The surface of the substrate on which the conductive film wiring is to be formed is subjected to surface treatment by the method of ...

Embodiment approach 3

[0110] As Embodiment 3, a silicon film pattern forming method as an example of the film pattern forming method of the present invention will be described. The silicon film pattern forming method of this embodiment is composed of a surface treatment process, a discharge process, and a heat treatment / light treatment process. Each process will be described below.

[0111] (surface treatment process)

[0112] Various materials such as Si wafer, quartz glass, glass, plastic film, and metal plate can be used as the substrate on which the silicon thin film pattern is to be formed. In addition, a semiconductor film, a metal film, a dielectric film, an organic film, etc., which are formed on the surface of these various raw material substrates as an underlayer, can also be used as a substrate to be patterned with a silicon thin film.

[0113] The surface of the substrate on which the silicon thin film pattern is to be formed is subjected to surface treatment by the method of Embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com