Method for producing benzene aromatic hydrocarbon from crude benzole

A technology for benzene series aromatic hydrocarbons and crude benzene, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve the problems of difficult long-term operation, unstable crude benzene, easy polymerization, etc., and achieves adaptability Strong, extended operation cycle, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

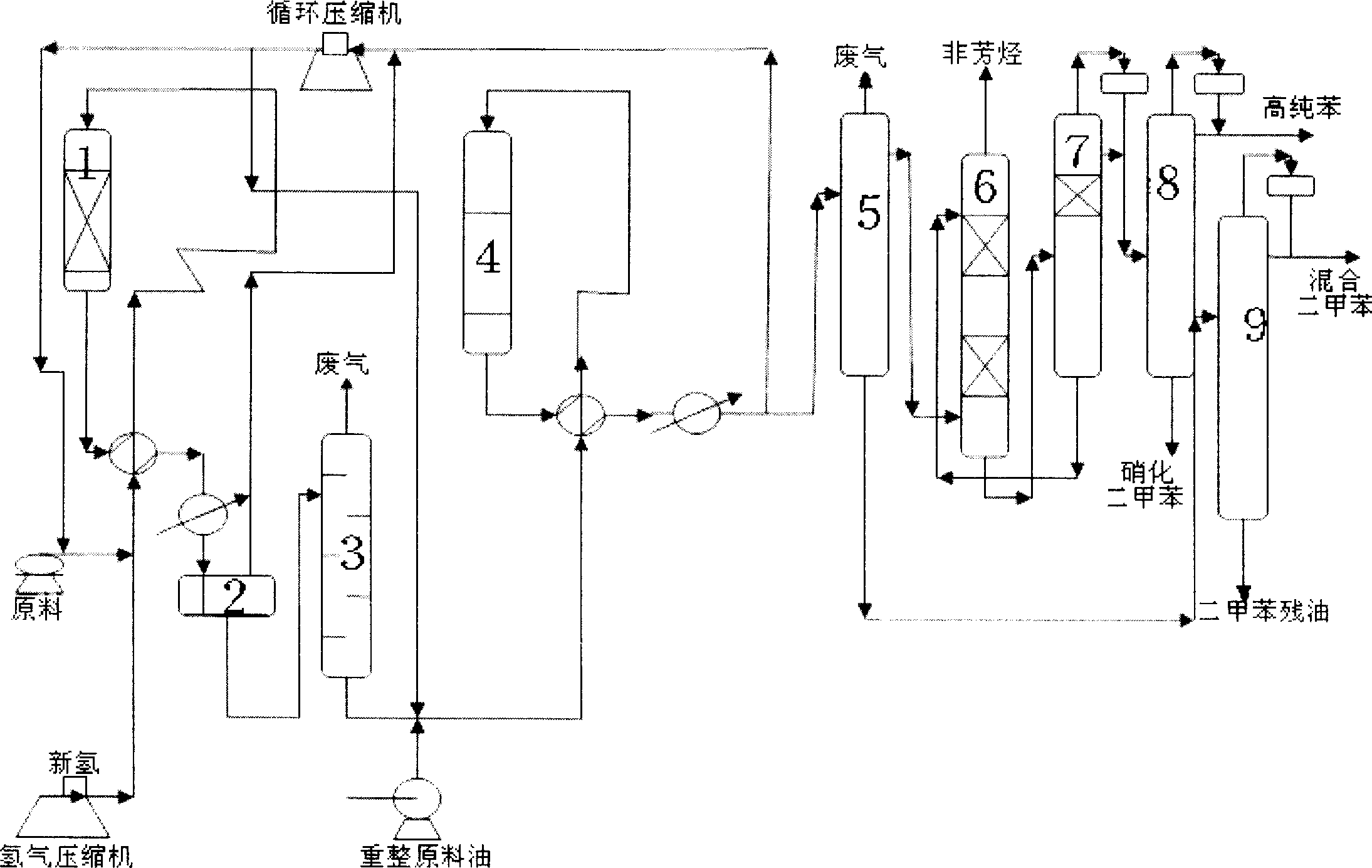

[0025] Crude benzene raw material 1, whose properties are shown in Table 1, enters the hydrogenation reactor 1 after being mixed with hydrogen, and the reaction conditions are shown in Table 2. The catalyst is a molybdenum-nickel hydrogenation catalyst, and the gas-liquid mixture discharged from the hydrogenation reactor enters the gas-liquid separation Device 2. The liquid phase is sent to the stripper 3, and the liquid product is collected after stripping, which is called hydrogenated oil. The properties and group composition of the hydrogenated oil are shown in Table 2. Hydrogenated oil is pre-distilled to separate heavy components containing xylene and light components containing benzene, toluene and non-aromatics. The former is sent to rectification to obtain petroleum grade mixed xylene, and the latter is extracted with N-formylmorpholine Distillation to separate non-aromatic hydrocarbons and rich solvents containing benzene and toluene. The rich solvents are then rectif...

Embodiment 2

[0027] Crude benzene raw material 2, its properties are shown in Table 1. See Table 2 for hydrogenation reaction conditions, properties and family composition of hydrogenated oil. Other reaction conditions, reaction steps are with embodiment 1. The product properties are shown in Table 3.

Embodiment 3

[0029] Crude benzene raw material 3, its properties are shown in Table 1. See Table 2 for hydrogenation reaction conditions, properties and family composition of hydrogenated oil. Other reaction conditions, reaction steps are with embodiment 1. The product properties are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com