In situ regenerating method and device for medium blocking discharging plasma active carbon

A technology of dielectric barrier discharge and plasma, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of activated carbon loss, high cost, secondary pollution, etc., achieve less activated carbon loss, short regeneration time, The effect of high regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

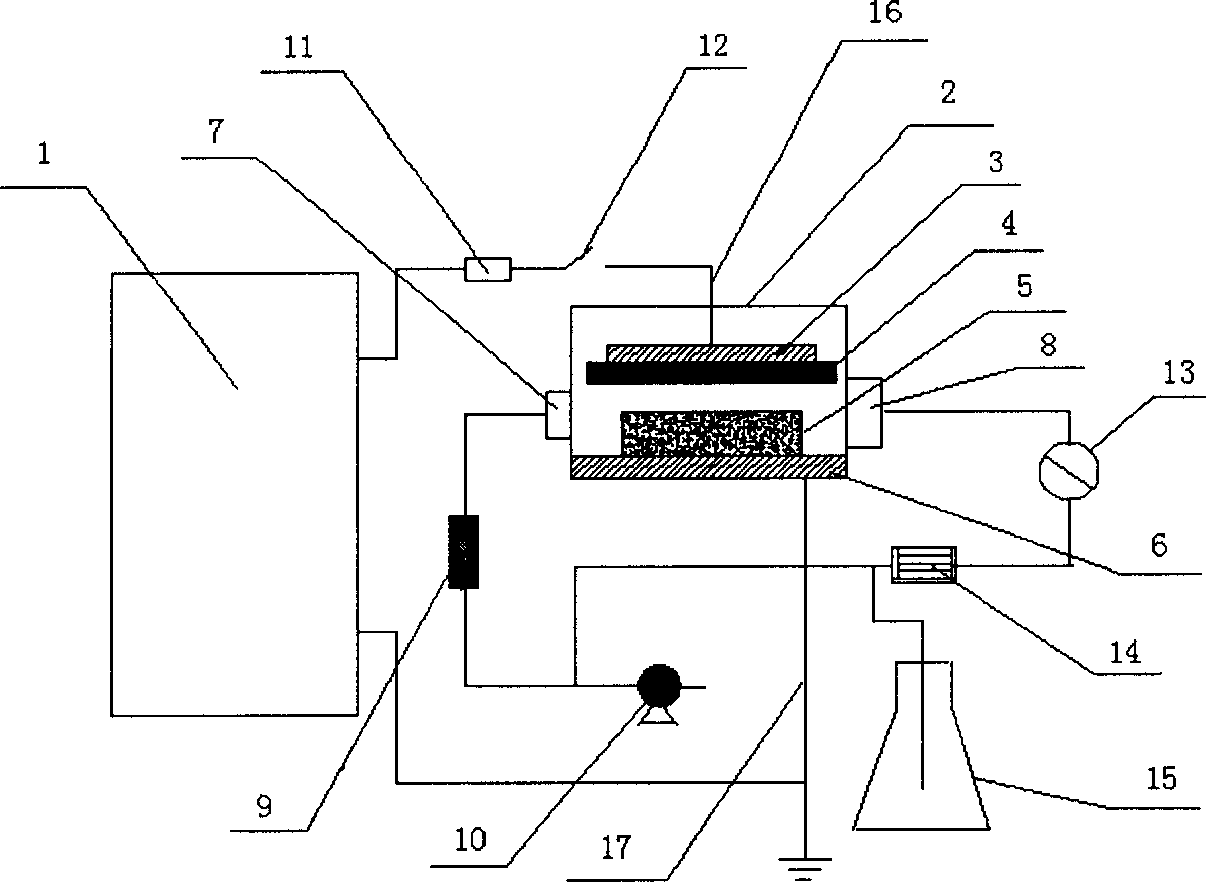

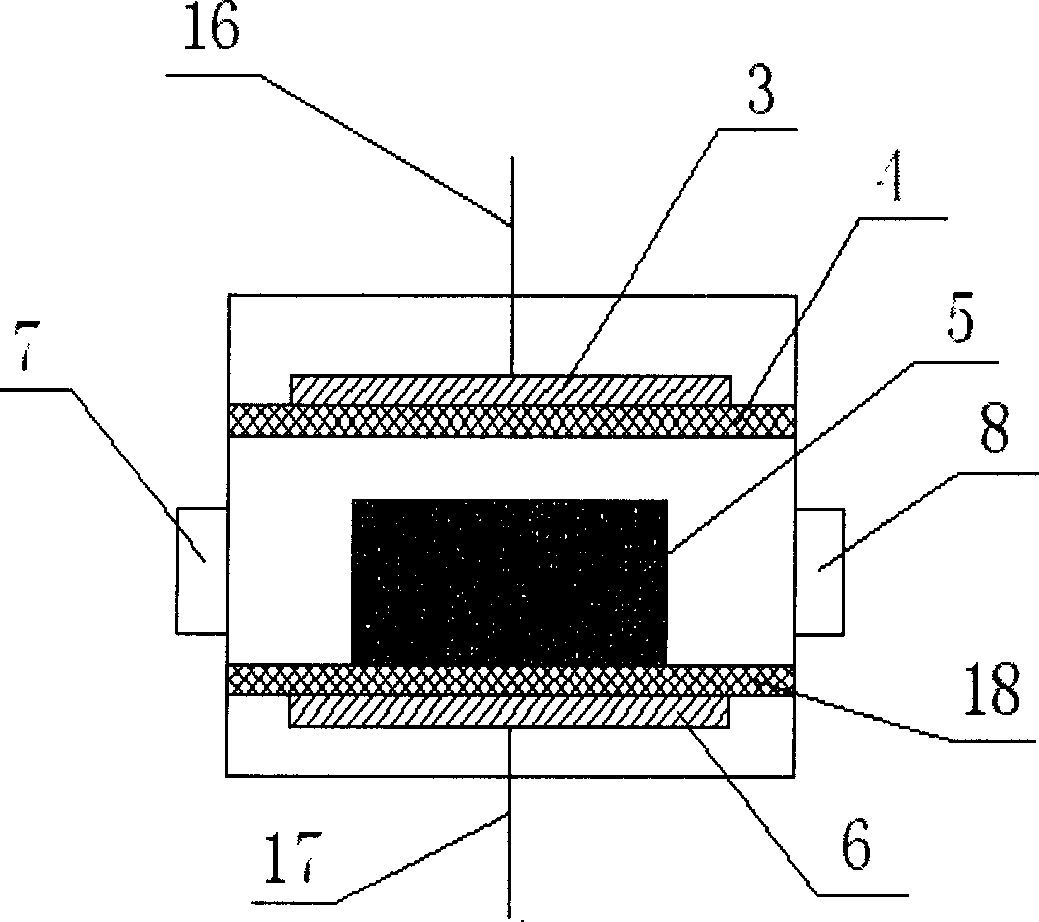

[0049] The device used in this example is figure 1 As shown, the frequency of the alternating high-voltage power supply 1 is 50HZ, the effective voltage range is 0-50kV, and the rated power is 1kW. The reactor shell is made of plexiglass, and the shape is a cuboid of 400mm×450mm×120mm. In this example, the discharge electrode and discharge medium are placed and selected figure 2 The high-voltage electrode 3 is a stainless steel plate of 200mm×200mm×4mm, the low-voltage electrode 6 is a stainless steel plate of 350mm×400mm×4mm, the quartz glass plate of 300mm×300mm×2mm is used as the high-voltage discharge medium 4, and the distance between the two electrode plates is 22mm , containing 2mm discharge medium; the gas is air; the activated carbon used is columnar coal-based activated carbon with a diameter of 3mm and an average length of 10mm, the thickness of the activated carbon is 9mm, and the moisture content of the activated carbon to be regenerated is 16%; in addition, thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size range | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com