Preparation of nano-structured DSA electrolytic electrode

A nanostructure, electrocatalysis technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of non-dense electrode surface coating, low oxygen evolution potential, low specific surface area, etc., and achieve easy control and dense coating surface , the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

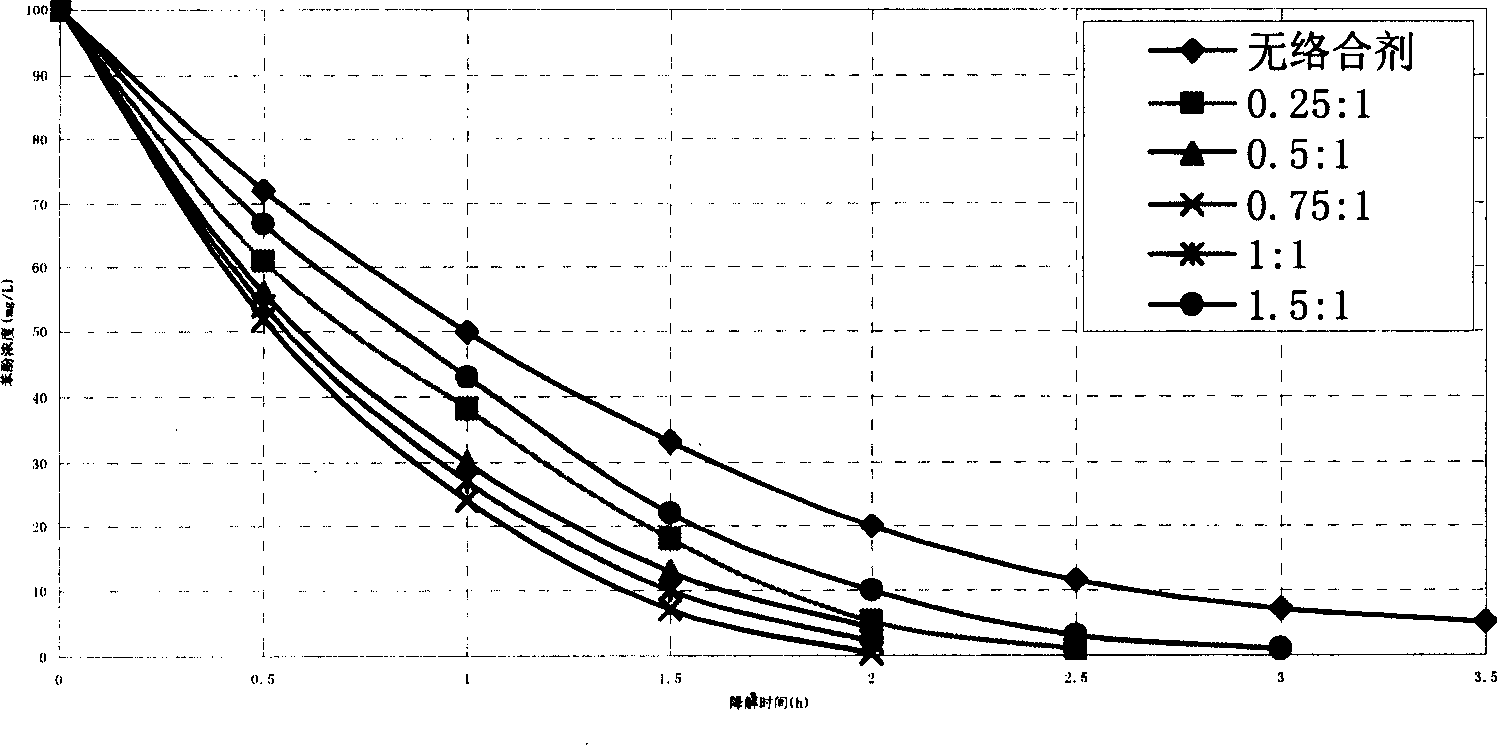

[0021] Embodiment 1: In this embodiment, on the basis of the papers published by the inventor, the influence of the usage amount of the complexing agent citric acid on the performance of the electrode is investigated in detail, and a set of experiments are designed:

[0022] keep SnCl 4 The concentration of the solution and ammonia water is 0.5mol / L unchanged, adding and SnCl 4 The molar ratios of citric acid were 0, 0.25:1, 0.5:1, 0.75:1, 1:1, and 1.5:1, respectively. 2 Preparation and performance study of nano-coating electrocatalytic electrodes”, the steps were prepared, heat treatment at 600 °C for 3 hours, and this process was repeated twice. Six electrodes were subjected to degradation experiments to investigate their effect on 100 mg / L phenol + 0.25 MNaSO 4 The degradation of the solution was followed by 4-aminoantipyrine spectrophotometry to track the change of phenol concentration during the degradation process. The solution volume is 100ml, and the current density...

specific Embodiment approach 2

[0045] Embodiment 2: The preparation method of the nanostructured DSA electrocatalytic electrode described in this embodiment includes the following detailed processes:

[0046] 1. Pretreatment of titanium substrate:

[0047] (1) Grinding: first grind with 40-mesh coarse sandpaper, then use 320-mesh fine sandpaper to make the surface of the titanium substrate appear silvery-white metallic luster, rinse with distilled water;

[0048] (2) Alkaline washing: then soak the titanium substrate with 40% NaOH solution by mass, heat it in a water bath at 95°C for 2 hours, and rinse it with distilled water;

[0049] (3) Pickling: soak the titanium substrate with oxalic acid solution with a content of 15% by mass, heat it in a water bath at 95°C for 2 hours, and rinse it with distilled water.

[0050] 2. Preparation process of sol to obtain precursors:

[0051] (1), weigh 0.44gSb 2 O 3 , add 3mL concentrated hydrochloric acid to dissolve it, add 7.6g citric acid (complexing agent) and...

specific Embodiment approach 3

[0058] Embodiment 3: The difference between this embodiment and the previous embodiment is that the following process is added between step a and step b in "B. Preparation of Sol ~10% rare earth nitrate or chloride, the rare earth is any one or any mixture of La, Ce, Pr, Nd, Sm, Eu, Gd, Dy.

[0059] The inventors have investigated the influence of various rare earth elements and the mixture of various rare earth elements on the performance of the electrode as a whole: the electrocatalytic performance of the electrode prepared by adding rare earth elements to the raw materials is not significantly improved, but the Doping increases the conductivity of the electrode, so that the electrode voltage drops under the condition of the same current density, thereby reducing the power consumption and improving the current efficiency. At the same time, the doping of rare earth elements also increases the oxygen evolution potential of the electrode.

[0060] Embodiment 4: The difference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com