Dedicated blade materials for line cutting of semiconductor materials

A material wire and semiconductor technology, applied in the field of blade materials, can solve the problems of unsatisfactory cutting, long production cycle, low efficiency, etc., and achieve the advantages of eliminating chemical treatment links, reducing drying energy consumption, and improving drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

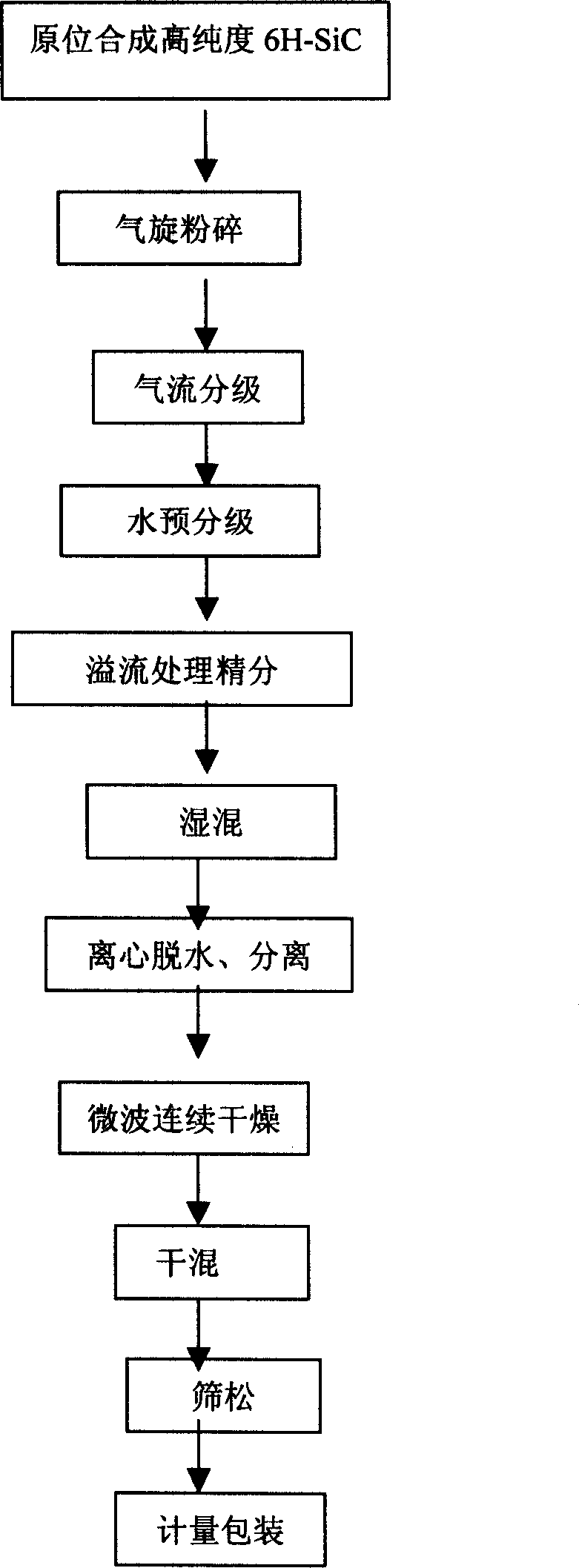

[0020] The special cutting edge material for semiconductor material wire cutting according to the present invention is made by in-situ synthesis of high-purity 6H-SiC from raw materials according to the following process steps:

[0021] 1. Cyclone crushing and air classification:

[0022] Take in-situ synthesized high-purity 6H-SiC and place it in the classification wheel, set the speed of the classification wheel to 800-820rpm, and the pressure in the grinding chamber of the classification wheel to 0.7Mpa, and crush the raw materials to particles with a particle size of less than 20μm; then classify Adjust the speed of the wheel to 2500-2800rpm, and set the induced air volume of the grading wheel to 3350-3500m 3 / h, classify the crushed micropowder, and separate the micropowder particles with a particle size of 4-20 μm for use;

[0023] 2. Water pre-classification, overflow treatment fine separation:

[0024] Take the micropowder obtained in the first step and put it in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com