Synergistic controlled soft switch contravariant type double-wire pulse MIG arc welding power supply

An arc welding power source and collaborative control technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of reducing power factor, short control cycle of inverter arc welding power source, fast dynamic response of the whole machine, etc. Switching loss and electrical stress, improving the ability to resist input interference, improving the effect of dynamic and static characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. However, the protection scope of the present invention is not limited to the scope indicated by the examples.

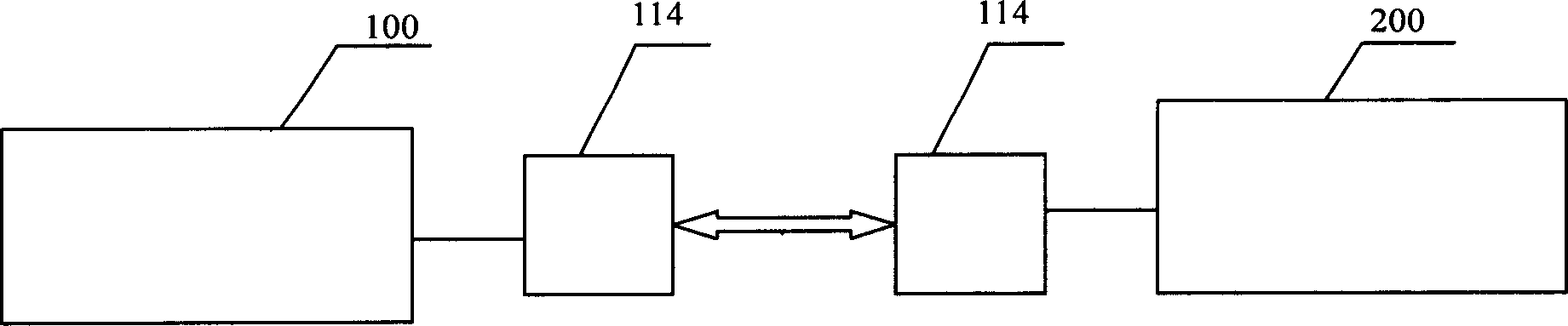

[0037] Such as figure 1 As shown, the soft-switching inverter dual-wire pulsed MIG arc welding power source with coordinated control includes a master pulsed MIG arc welding power source 100, a slave machine pulsed MIG arc welding power source 200, and a master pulse MIG arc welding power source 100 and a slave machine pulsed MIG arc welding power source respectively. The digitalized coordination control module 114 connected to the arc welding power source 200 is connected through the CAN bus. The master pulse MIG arc welding power source 100 and the slave pulse MIG arc welding power source 200 have the same structure.

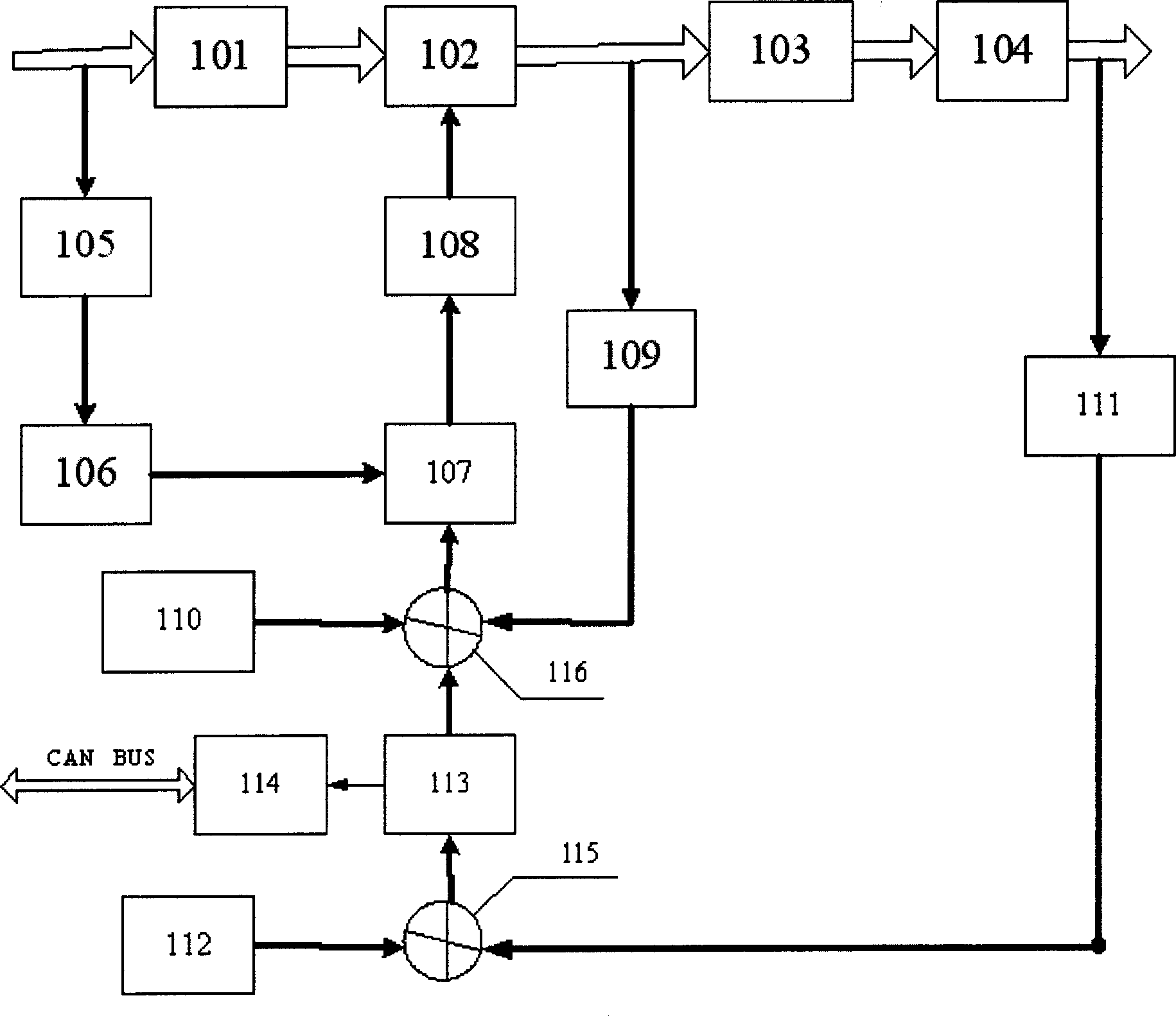

[0038] Such as figure 2 As shown, the master pulse MIG arc welding power supply 100 or the slave pulse MIG arc w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com