Camptothecin type medicine loaded on high molecular nano-microsphere, and its prepn. method

A technology of nano-microspheres and camptothecin, which is applied in the direction of medical preparations of non-active ingredients, drug combinations, anti-tumor drugs, etc., can solve the problems of low affinity and self-aggregation tendency, and achieve enhanced anti-tumor effects in vivo, The method is simple and easy, and the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0031] Preparation Example 1: Preparation of poly(lactide-caprolactone)-polyethylene glycol-poly(lactide-caprolactone) amphiphilic block copolymer (PCLLA-PEG-PCLLA)

[0032] Add calculated amounts of caprolactone (CL, Aldrich, USA) and lactide (LA, Aldrich, USA) and 0.1% (w / w) octanoic acid to a polymerization tube filled with an appropriate amount of polyethylene glycol (PEG). Stannous, wherein the number average molecular weight of PEG varies from 6000 to 10000 depending on the requirements of the product, but it is not limited to the above molecular weights. The tube was sealed under vacuum and placed at 130°C for 48 hours. The crude product obtained by the reaction was dissolved in chloroform and precipitated in a large amount of cold methanol to remove unreacted monomers and other low-molecular weight substances, and then the precipitate was collected and washed with water for several times and then dried under reduced pressure to obtain PCLLA-PEG-PCLLA 3 block polymers....

preparation example 2

[0033] Preparation example 2: Preparation of polycaprolactone-polyethylene glycol-polycaprolactone amphiphilic block copolymer (PCL-PEG-PCL)

[0034] Add a calculated amount of caprolactone (CL, Aldrich, USA) and 0.1% (w / w) stannous octoate into a polymerization tube filled with an appropriate amount of polyethylene glycol (PEG), wherein the number average molecular weight of PEG is based on the The requirements of the products are different, ranging from 2000, 6000 and 10000 respectively, but it is not limited to the above molecular weights. The tube was sealed under vacuum and placed at 130°C for 48 hours. The crude product obtained by the reaction was dissolved in chloroform and precipitated in a large amount of cold methanol to remove unreacted monomers and other low molecular weight substances, and then the precipitate was collected and washed with water several times and dried under reduced pressure to obtain PCL-PEG-PCL three block polymers. Corresponding to PEG molec...

preparation example 3

[0035] Preparation example 3: Preparation of diethylenetriaminepentaacetic acid-polycaprolactone-diethylenetriaminepentaacetic acid (DTPA-PCL-DTPA)

[0036] Diethylenetriaminepentaacetic acid (DTPA) dianhydride was prepared according to literature (CH Paik et al., Journal of Nuclear Medicine, Vol 24, Issue 12 1158-1163). The prepared DTPA bis-acid anhydride is stored in a desiccator after being purified and dried. A calculated amount of ethylene glycol (Aldrich, USA) was added into a sealed glass tube, and α, ω-dihydroxypolycaprolactone with a molecular weight of 2000 was prepared by ring-opening polymerization under the catalysis of stannous octoate. Add a certain amount of α, the anhydrous DMF solution (30%) of ω-dihydroxy polycaprolactone in the dropping funnel on the 100mL three-necked bottle, add excessive DTPA bis-acid anhydride and catalytic amount in the three-necked bottle The 4-dimethylaminopyridine (DMAP) was stirred and dissolved with an appropriate amount of anhy...

PUM

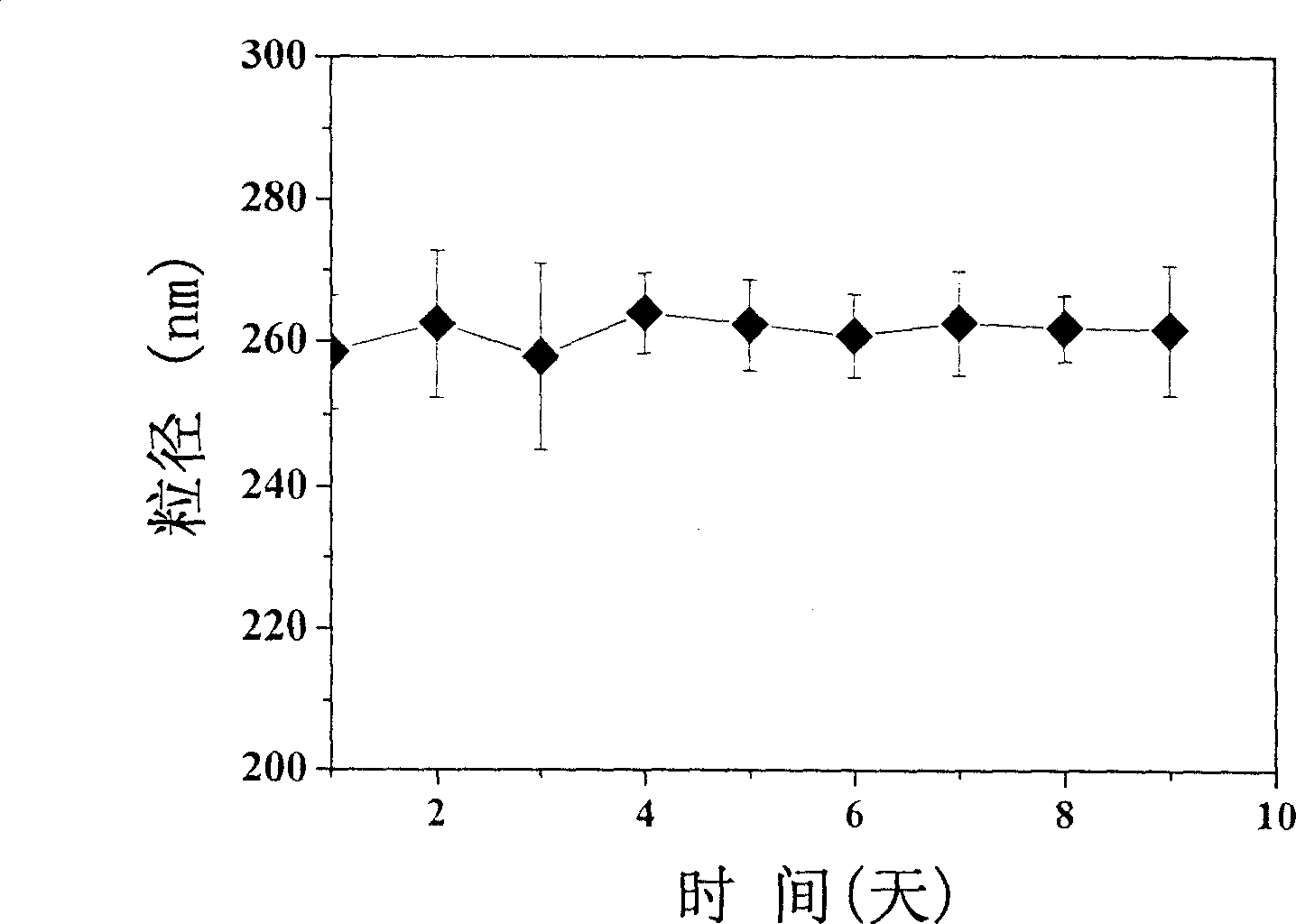

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com