Optical flow meter for measuring gases and liquids in pipelines

A pipeline, optical technology, applied in the measurement of flow/mass flow, measurement device, fluid velocity measurement, etc., can solve problems such as being unsuitable for field applications, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

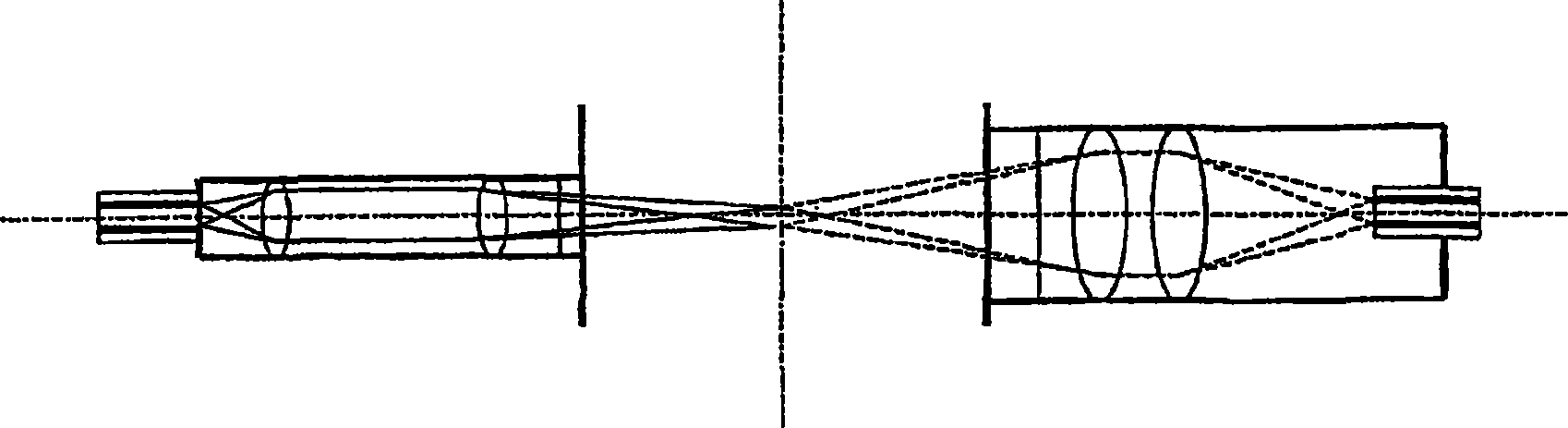

[0038] image 3 An optical flow meter constructed in accordance with a preferred embodiment for determining the flow rate of a fluid in a pipe by measuring the velocity of small particles carried by the fluid flow is shown in . The flowmeter device consists of the following components: an optomechanical head 10 inserted between adjacent flanges 11 in a pipe 12, an electro-optical assembly 13 containing two laser sources 14, two scattered signal photodetectors 54 and 55, Processing electronics 15 , and an optical extension cable guide 16 connecting the optoelectronic assembly 13 to the optomechanical head 10 . In this configuration, the optoelectronic assembly 13 can be remotely located so that no electrical potential exists at the optomechanical head 10, which is desirable when fluid passing through the pipeline, such as natural gas, could be ignited by a spark or short circuit. Furthermore, the fiber optic terminations at the optomechanical head 10 are compact, robust and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com