A two-way baking cover for a steel bucket

A technology for a steel bucket and a cover, which is applied to the baking field of steel buckets or iron cans, can solve the problems of wasting energy, and the flame of a combustion device cannot reach the bottom for most of the time, so as to improve thermal efficiency, reduce heat loss, The effect of high heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

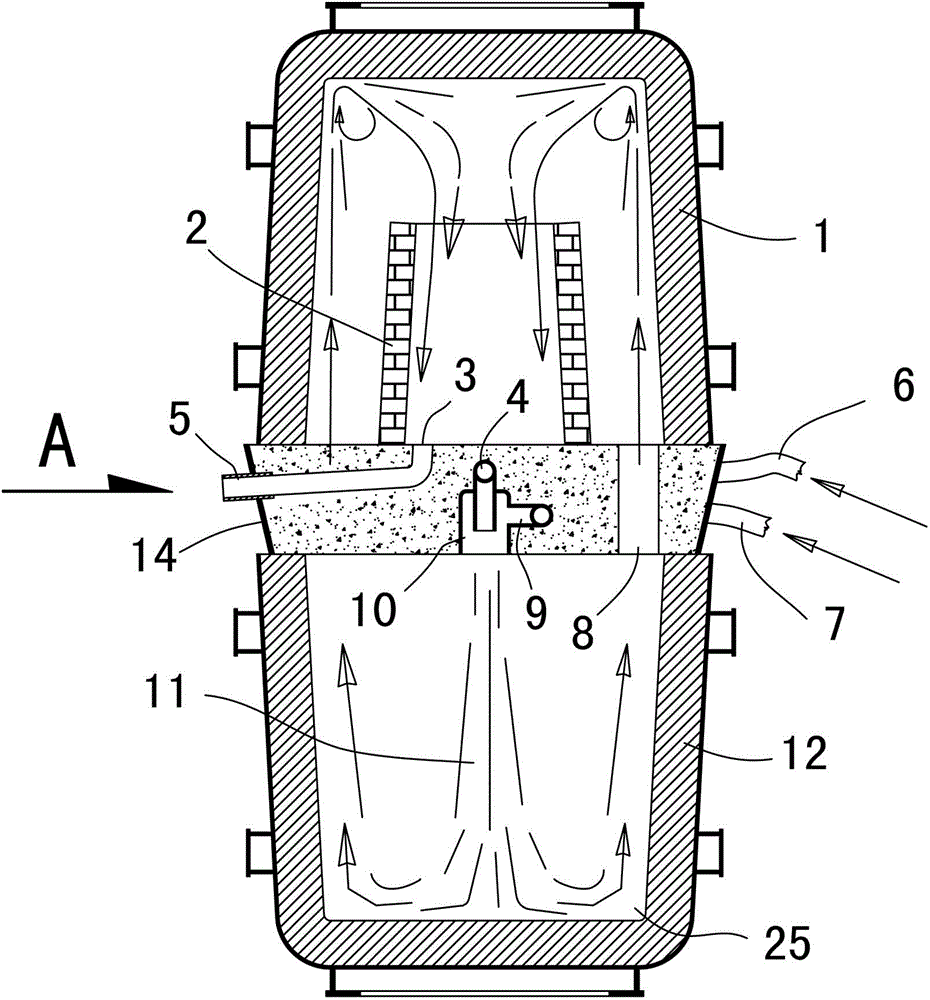

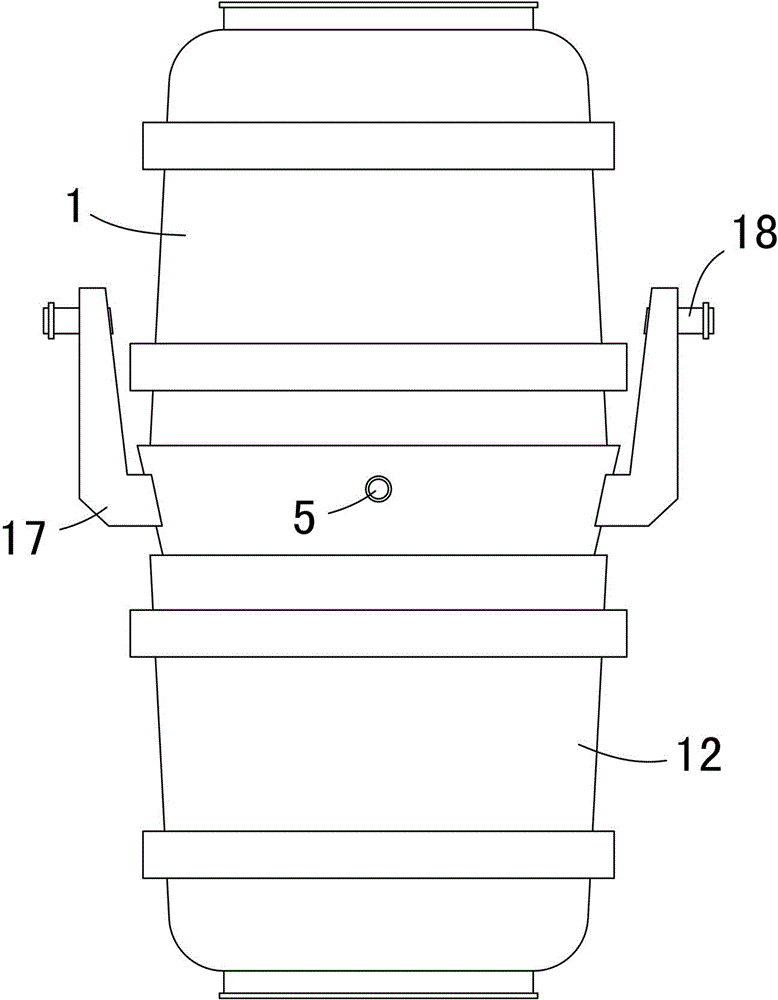

[0061] as attached figure 1 , 2 A two-way baking cover for a steel drum is shown, which includes a baking cover body, a burner 10 is arranged in the middle of the lower bottom of the baking cover body, and a combustion-supporting air duct 4 and a gas pipe are arranged inside the baking cover body 9. Both the combustion-supporting air pipe 4 and the gas pipe 9 are connected to the burner 10, and the side wall of the baking cover body is provided with a combustion-supporting air inlet 6 and a gas inlet 7, and the combustion-supporting air inlet 6 is connected to the combustion-supporting air pipe 4 The gas inlet 7 communicates with the gas pipe 9.

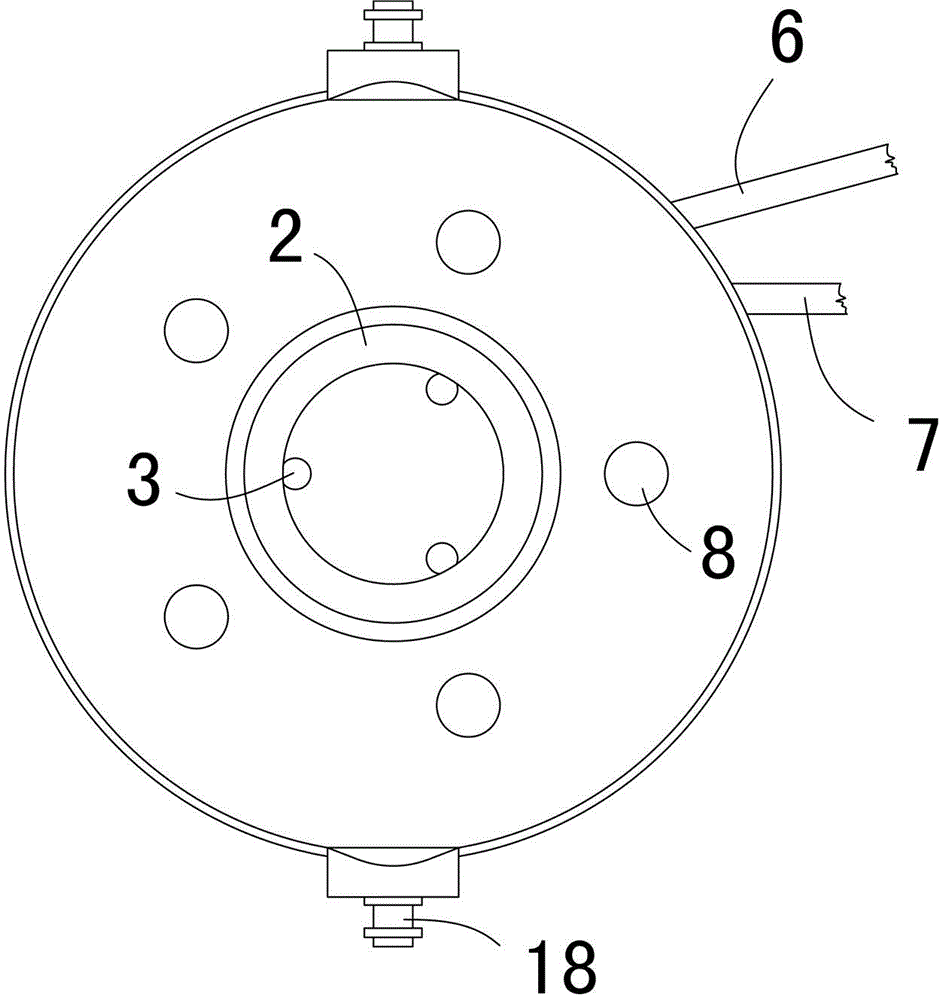

[0062] The middle part of the upper bottom surface of the baking cover body is provided with a guide tube 2, and the baking cover body is provided with a plurality of channeling channels 8 that penetrate up and down. The outer side of the cylinder 2; the upper bottom surface of the baking cover body is provided with a plurality of...

Embodiment 2

[0069] as attached Figure 5 As shown, on the basis of Embodiment 1 in this embodiment, a gas distribution ring pipe 16 is arranged inside the baking cover body, and the end of the gas pipe 9 communicates with the gas distribution ring pipe 16, and the gas distribution ring A plurality of gas injection pipes 32 are evenly arranged on the pipe 16, and the end of the combustion-supporting air pipe 4 is provided with an air jet pipe 33 matching the number of the gas injection pipes 32, and the air jet pipe 33 is obliquely formed on the combustion-supporting air pipe 4 The ends are arranged radially, and a gas injection pipe 32 and a corresponding air jet pipe 33 are arranged side by side to form the burner 10 together.

[0070] This embodiment is an implementation of the burner 10 in the first embodiment. When oxygen is used to support combustion, the flow rate of multiple air jet tubes 33 is reduced by 79% compared with air, and the amount of tail flame discharge is correspondi...

Embodiment 3

[0072] as attached Figure 8-14 As shown, the difference between this embodiment and Embodiment 1 is that the upper bottom surface of the baking cover body is provided with a heat exchange boss 13, and the heat exchange boss 13 is formed on the inner side of the air guide tube 2, and its height is lower than The height of the guide tube 2. A plurality of heat exchange air pipes 19 are evenly arranged in the heat exchange boss 13, and a combustion air distribution ring pipe 15 is arranged in the baking cover body, and the heat exchange air pipes 19 are evenly distributed in the combustion air distribution ring pipe 15 Above, the inlet end of the heat exchange air duct 19 communicates with the combustion air inlet 6 through the combustion air distribution ring 15 , and the outlet end of the heat exchange air duct 19 communicates with the combustion air duct 4 .

[0073] For the arrangement of the heat exchange air ducts 19 in the heat exchange boss 13, refer to Figure 8-10 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com