Process for degradation of organic waste water by fly ash

A technology of organic wastewater and fly ash, which is applied in energy wastewater treatment, adsorption water/sewage treatment, etc., can solve the problem of high cost of wastewater treatment technology, achieve the effects of thorough degradation of organic matter, improvement of treatment efficiency, and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for degrading organic waste water with fly ash, the method uses fly ash as an adsorbent for organic matter in the waste water. The method includes the following steps:

[0020] a. Fully mix fly ash and waste water, the mass ratio of fly ash and waste water is 0.8%~1.5%;

[0021] b. Adjust the acidity of the waste water mixture, and its pH value is 1-4;

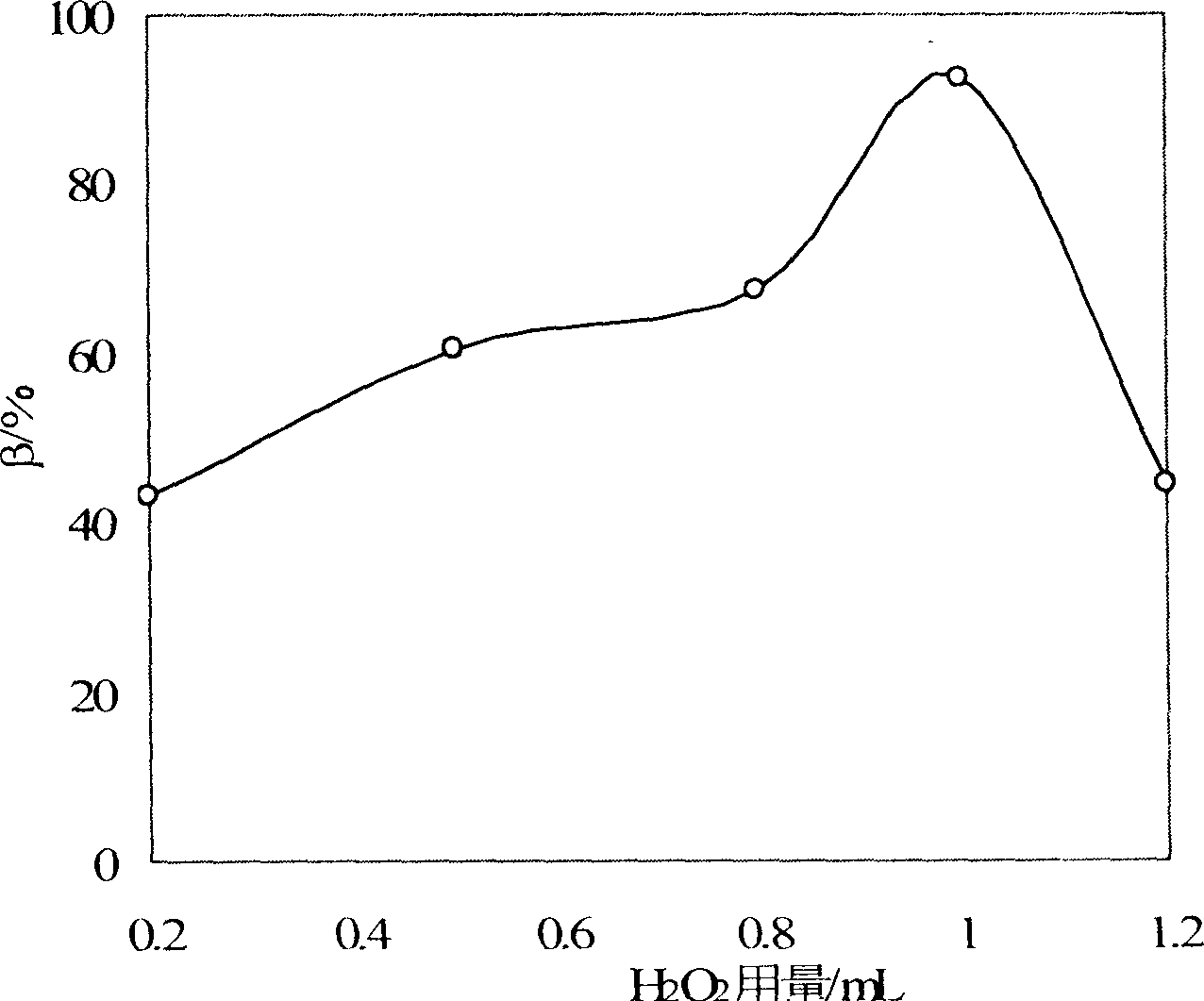

[0022] c, adding hydrogen peroxide in the waste water mixed liquid, its addition is 0.25%~0.4% of the quality of the waste water mixed liquid, so that it forms Fenton-like reagent with the soluble metal ion in the fly ash;

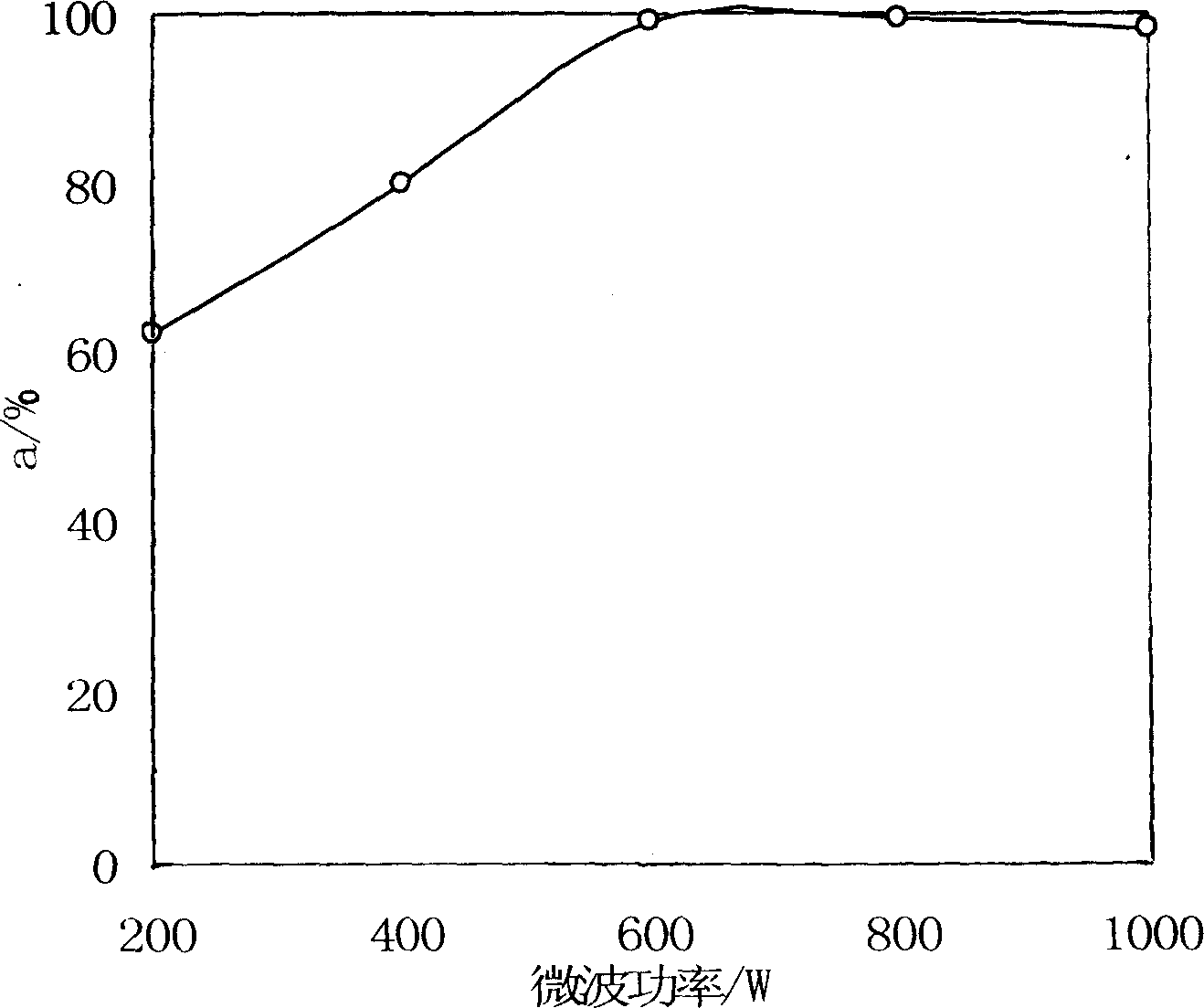

[0023] d. Let the waste water mixture pass through the glass or ceramic pipe with microwave field, and the time for each particle to pass through the pipe is 3-5 minutes; the microwave frequency is 2000-2800MHz, and the power is 600-1000W;

[0024] e. Finally, filter, precipitate, detect, collect fly ash containing pollutants, and discharge or recycle the treated water.

[0025] Disclose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com