Paste type plate manufacturing method and alkaline accumulator using same

A manufacturing method and storage battery technology, applied to alkaline storage batteries, alkaline storage battery electrodes, etc., can solve the problems of decreased storage capacity, increased internal impedance of storage batteries, and shortened tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] The feature of the present invention is that the part with active matter (active matter) in the cutting part is cut off by a cutting tool (scissors tool), and the part without active matter is punched out by a stamping tool, thereby prolonging the life of the tool and preventing warping of the pole plate section Curved edges and bumps.

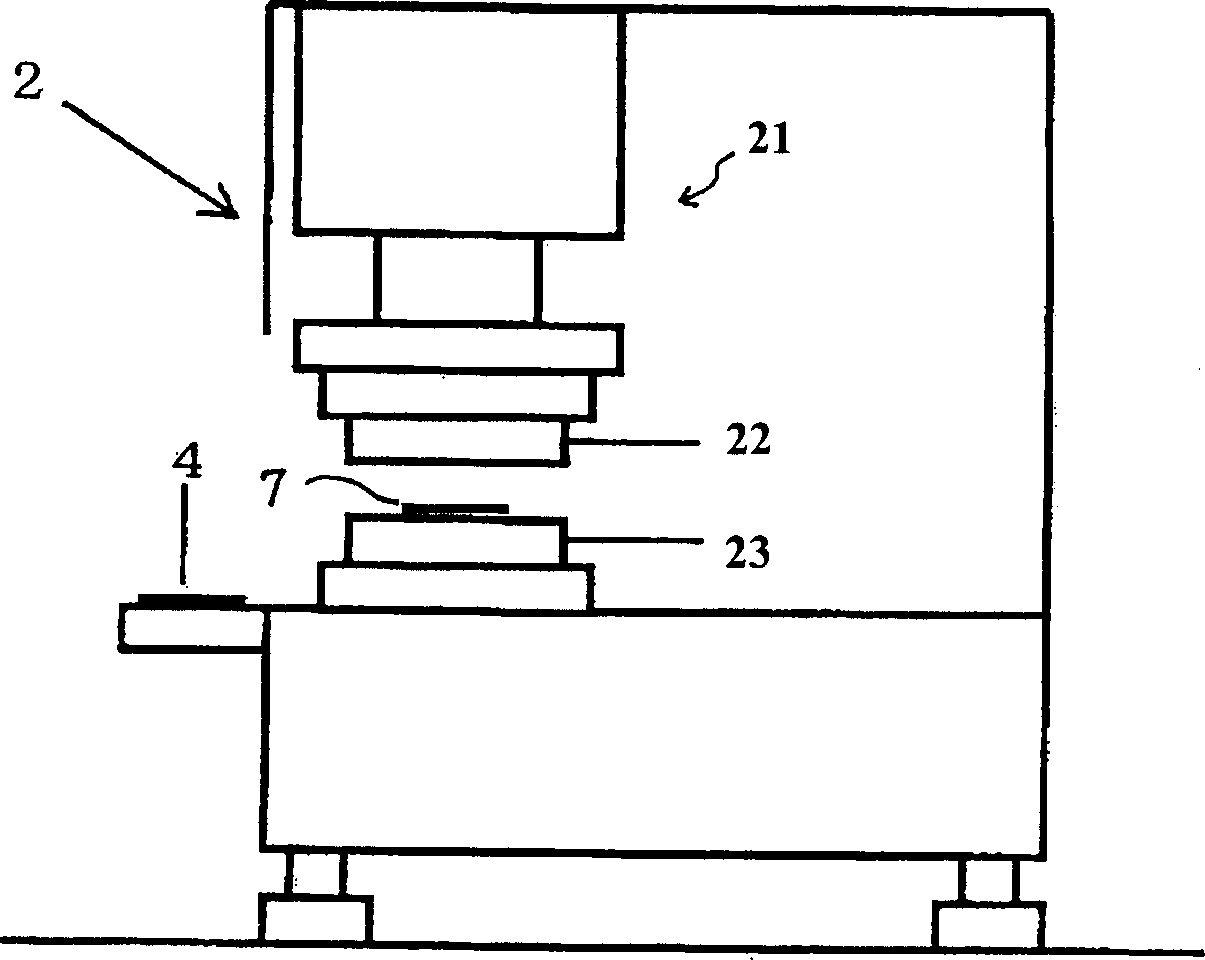

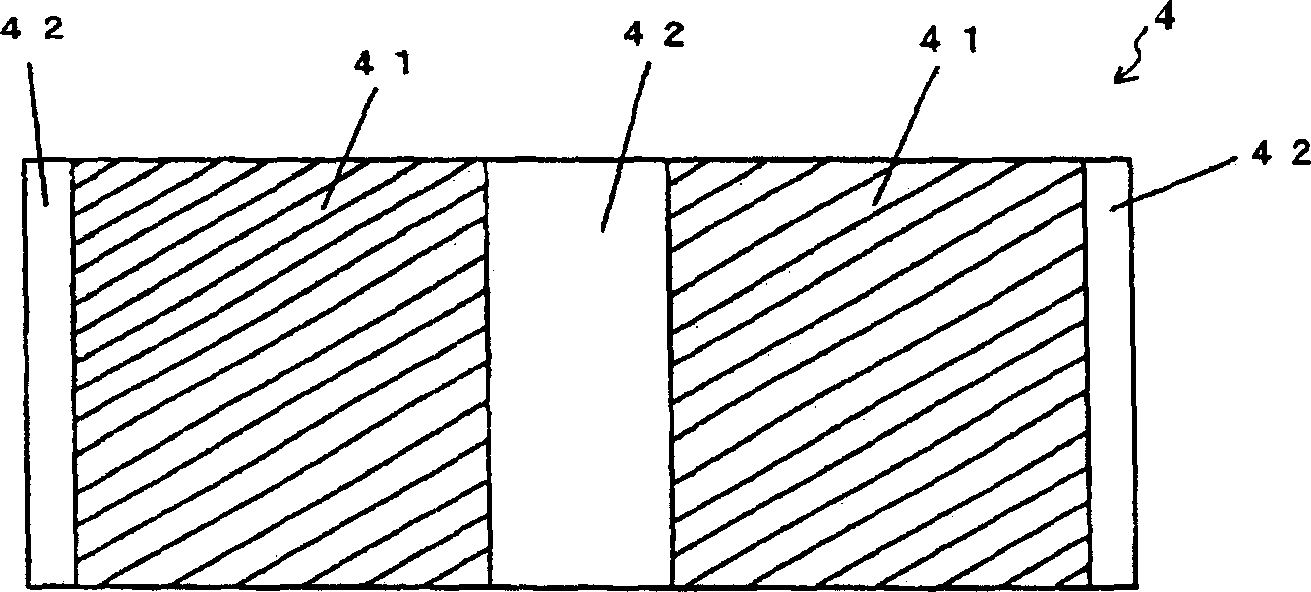

[0029] figure 1 A cutting machine (shearing machine) 1 for carrying out the manufacturing method of the present invention is shown. Among them, 11 is a driving device, 12 is an upper cutting tool, 13 is a lower cutting tool, 14 is a pedestal for installing the lower cutting tool 13, 15 is a control device for changing the speed of the driving roller, 16 is a driving roller, and 17 is a conveyor. roll. The paste type electrode plate of the present invention can be applied to either a positive electrode plate or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com