Novel chrome steel high speed steel and heat treatment process thereof

A technology of high-speed steel and chromium steel, which is applied in the field of new chromium steel high-speed steel and its heat treatment process, can solve the problems of low production cost and high production cost, increase hardenability, reduce production cost, and save molybdenum usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]New chromium steel high-speed steel, the high-speed steel by weight percentage includes: carbon C0.95%, silicon Si0.3%, manganese Mn0.3%, chromium Cr10%, tungsten W5.5%, molybdenum Mo1.0%, Vanadium V1.0%, Nickel Ni0.2%, Cobalt Co0.5%, Niobium Nb1.2%, Titanium Ti0.3%, Rare Earth Elements 0.05%, Sulfur S≤0.015%, Phosphorus P≤0.02%, and the balance is Iron Fe.

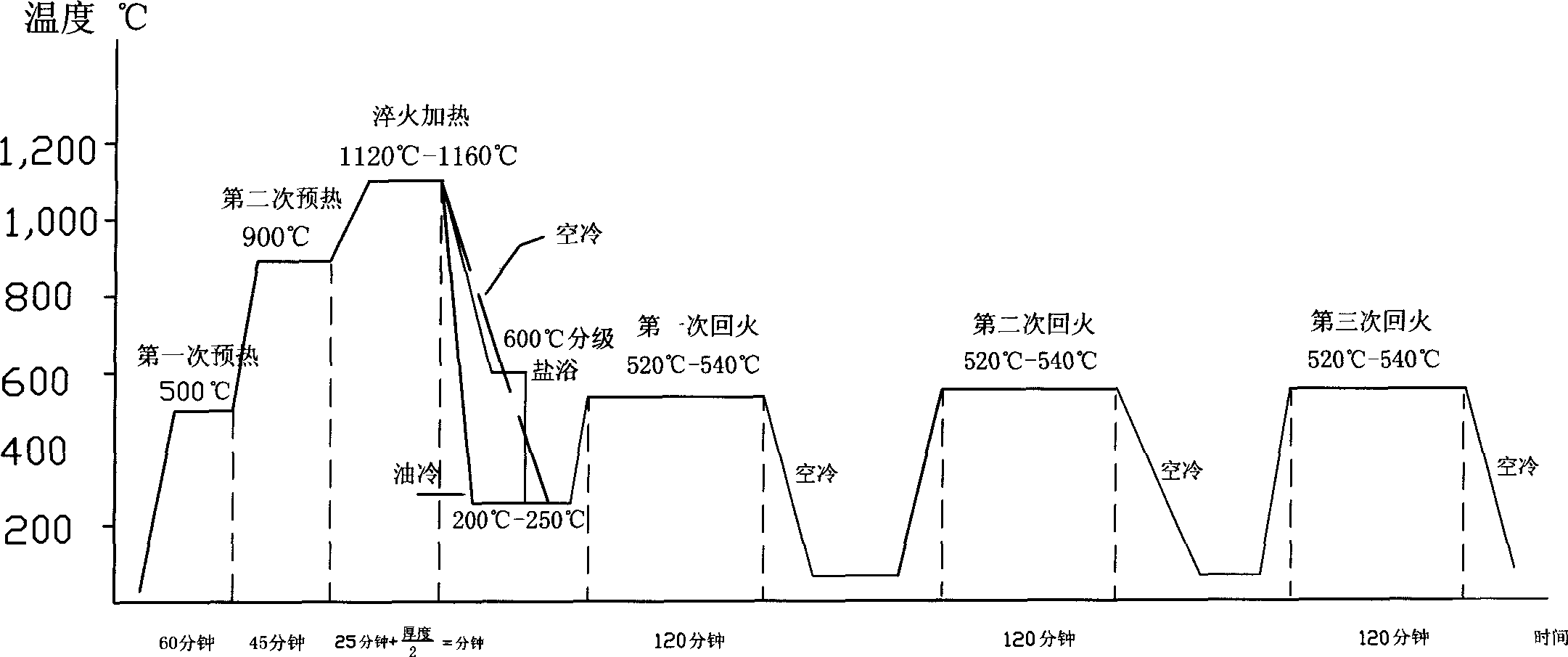

[0038] The heat treatment process of the above-mentioned novel chromium steel series high-speed steel comprises the following steps:

[0039] (1), the first preheating, the temperature is 500 ℃, and the preheating time is 60 minutes;

[0040] (2), the second preheating, the temperature is 900 ℃, and the preheating time is 45 minutes;

[0041] (3) Quenching heating, the quenching heating temperature is 1120°C-1160°C, the quenching time is: (25+material thickness / 2) minutes, and then oil-cooled to 200°C-250°C;

[0042] (4) For the first tempering, the tempering temperature is 520°C to 540°C, the tempering time is 1...

Embodiment 2

[0046] A new type of chromium steel high-speed steel, the high-speed steel includes: carbon C0.9%, silicon Si0.2%, manganese Mn0.2%, chromium Cr9.5%, tungsten W5.0%, molybdenum Mo0.6 %, Vanadium V0.6%, Nickel Ni0.1%, Cobalt Co0.3%, Niobium Nb0.8%, Titanium Ti0.3%, Rare Earth Elements 0.05%, Sulfur S≤0.015%, Phosphorus P≤0.02%, and the rest The amount is iron Fe.

[0047] The heat treatment process of the above-mentioned novel chromium steel series high-speed steel comprises the following steps:

[0048] (1), the first preheating, the temperature is 500 ℃, and the preheating time is 60 minutes;

[0049] (2), the second preheating, the temperature is 900 ℃, and the preheating time is 45 minutes;

[0050] (3) Quenching heating, the quenching heating temperature is 1120℃~1160℃, the quenching time is: (25+material thickness / 2) minutes, then cooling in salt bath, grading heat preservation at 600℃, and then salt bath to 200℃~250℃ ;

[0051] (4) For the first tempering, the temper...

Embodiment 3

[0055] A new type of chromium steel high-speed steel, the high-speed steel by weight percentage includes: carbon C1.0%, silicon Si0.4%, manganese Mn0.4%, chromium Cr10.5%, tungsten W6.0%, molybdenum Mo1.5 %, vanadium V1.5%, nickel Ni0.3%, cobalt Co0.8%, niobium Nb1.8%, titanium Ti0.3%, rare earth 0.05%, sulfur S≤0.015%, phosphorus P≤0.02%, the rest For iron Fe.

[0056] The heat treatment process of the above-mentioned novel chromium steel series high-speed steel comprises the following steps:

[0057] (1), the first preheating, the temperature is 500 ℃, and the preheating time is 60 minutes;

[0058] (2), the second preheating, the temperature is 900 ℃, and the preheating time is 45 minutes;

[0059] (3) Quenching heating, the quenching heating temperature is 1120°C-1160°C, the quenching time is: (25+material thickness / 2) minutes, and then air-cooled to 200°C-250°C;

[0060] (4) For the first tempering, the tempering temperature is 520°C to 540°C, the tempering time is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com