Positive resist composition, manufacture method and application of the same

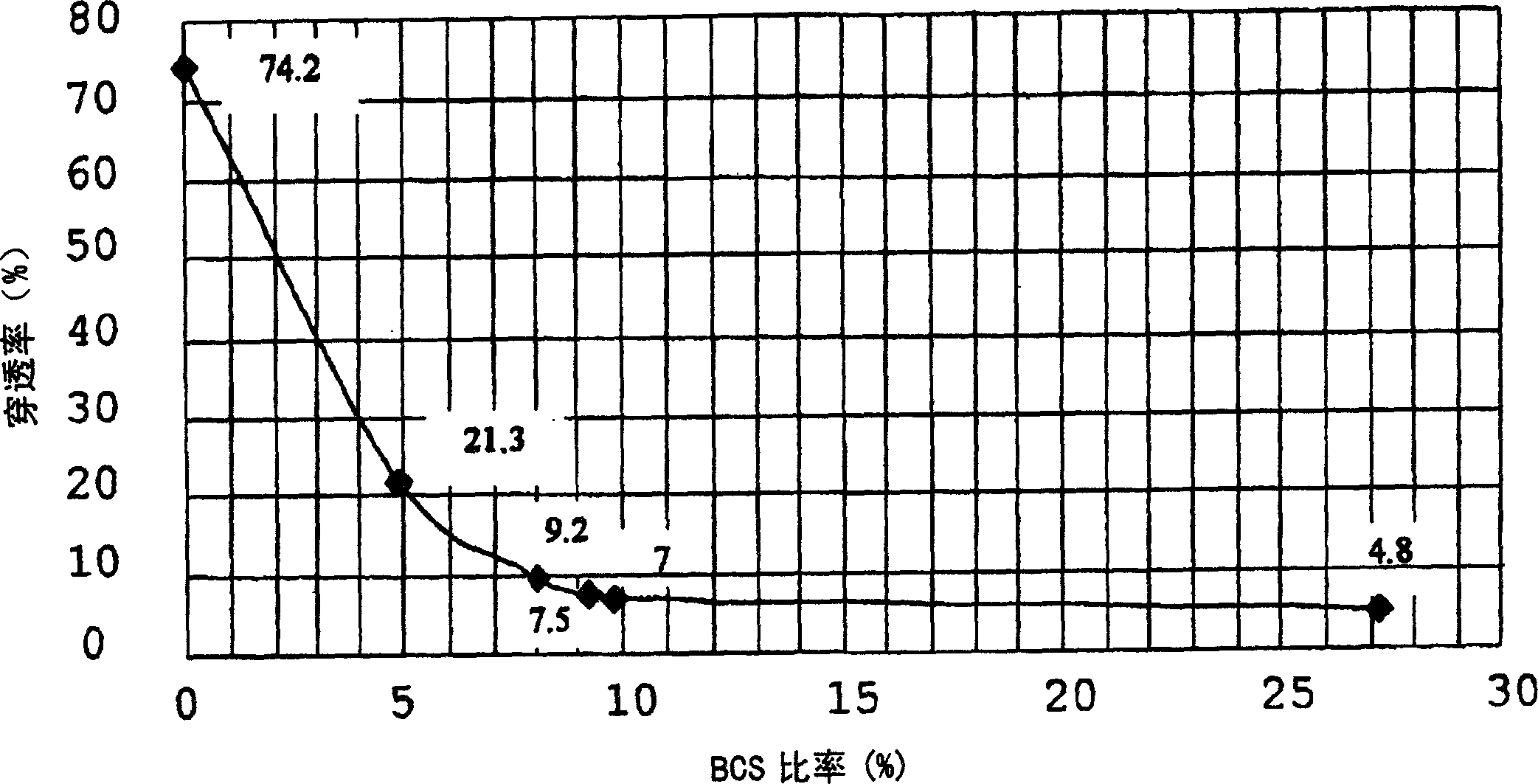

A positive photoresist and composition technology, which is applied to the positive photoresist composition and its preparation and application fields, can solve the problems of poor resolution, inability to generate pattern shapes, etc., and achieve high sensitivity, line edge roughness, etc. Low and high resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

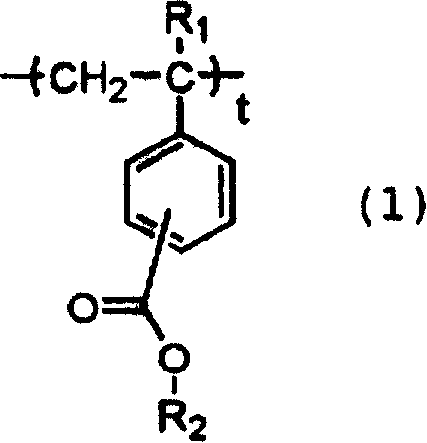

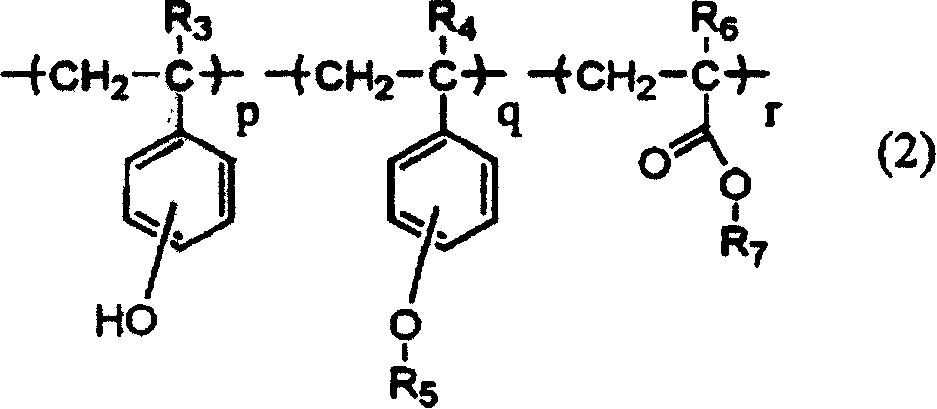

Method used

Image

Examples

Embodiment

[0145] The following shows synthesis examples, comparative synthesis examples, implementation examples and comparative examples. Although the present invention can be described more specifically, the present invention is not limited thereto.

[0146] [Synthesis example 1]

[0147] 101.1 g of 4-ethoxyethoxystyrene and 38.9 g of 4-tert-butoxycarbonylstyrene were placed in a 1 L flask, and 520 g of toluene was added as a solvent. The reaction vessel was cooled to -70°C under nitrogen, and vacuum degassing and nitrogen flow were repeated three times. After raising the temperature to room temperature, 9.59 g of AIBN[2,2'-azobisisobutyronitrile] was added as a polymerization initiator, and after raising the temperature to 62°C, it was reacted for 20 hours. In this reaction solution, a mixture of 1200 mL of methanol and 50 mL of water was mixed dropwise, stirred for 15 minutes, and left to stand for 2 hours, then the lower layer [polymer layer] was separated. The obtained polymer l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com