Method for preparing injectable polyletic acid micro-carrier/chitosan hydrogel composite scaffold

A technology of composite scaffold and polylactic acid, which is applied in the direction of coating, etc., can solve the problems of low strength, wandering, and difficult molding, etc., and achieve the effect of improving strength, mild implementation conditions, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

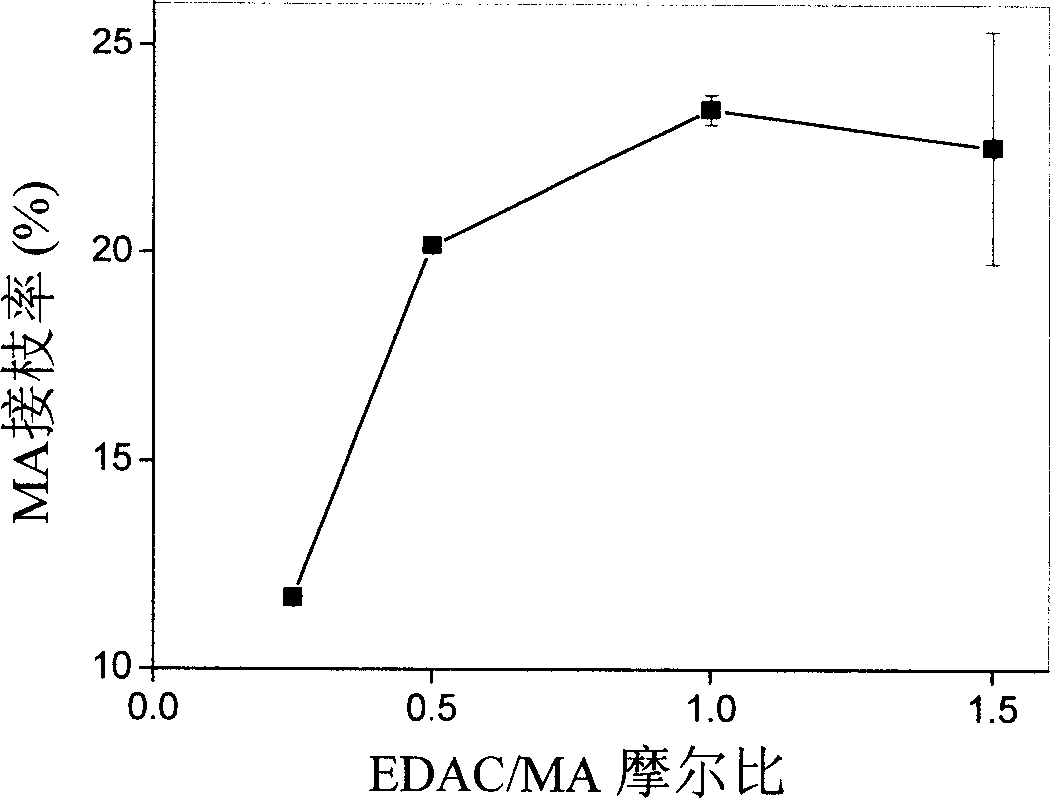

[0024] Weigh 800mg of chitosan (CS) and place it in a 250ml Erlenmeyer flask, add 100ml triple distilled water and 420μl MA (0.48mmol), after the CS is completely dissolved, add 930mg EDAC (0.48mmol), then stir the reaction at room temperature 24h. In order to remove unreacted MA and other small molecular products, the reaction mixture was placed in a dialysis bag with a cut-off molecular weight of 10,000 Da, dialyzed in a large amount of triple-distilled water at room temperature for 3 days, and the triple-distilled water was changed 2 to 3 times a day. Finally, the liquid was frozen and freeze-dried to obtain MA-grafted chitosan (CM). The CM yields are all greater than 90%, and the MA grafting amount is about 23%, see figure 1 ; Swellable in water. Dissolve the above 400mg CM in 50ml triple distilled water containing 210μl LA (0.2mmol), and add 460mgEDAC (0.24mmol) after complete dissolution. After the mixture was stirred at room temperature for 24 hours, the reaction mix...

example 2

[0026] Weigh 800mg of chitosan and place it in a 250ml Erlenmeyer flask, add 100ml triple distilled water and 420μl MA (0.48mmol), after the CS is completely dissolved, add 232.5mg EDAC (0.12mmol), then stir the reaction at room temperature for 24h . In order to remove unreacted MA and other small molecular products, the reaction mixture was placed in a dialysis bag with a cut-off molecular weight of 10,000 Da, dialyzed in a large amount of triple-distilled water at room temperature for 3 days, and the triple-distilled water was changed 2 to 3 times a day. Finally, the liquid was frozen and freeze-dried to obtain MA-grafted chitosan (CM). The CM yields are all greater than 90%, and the MA grafting amount is about 11.74%, see figure 1 .

example 3

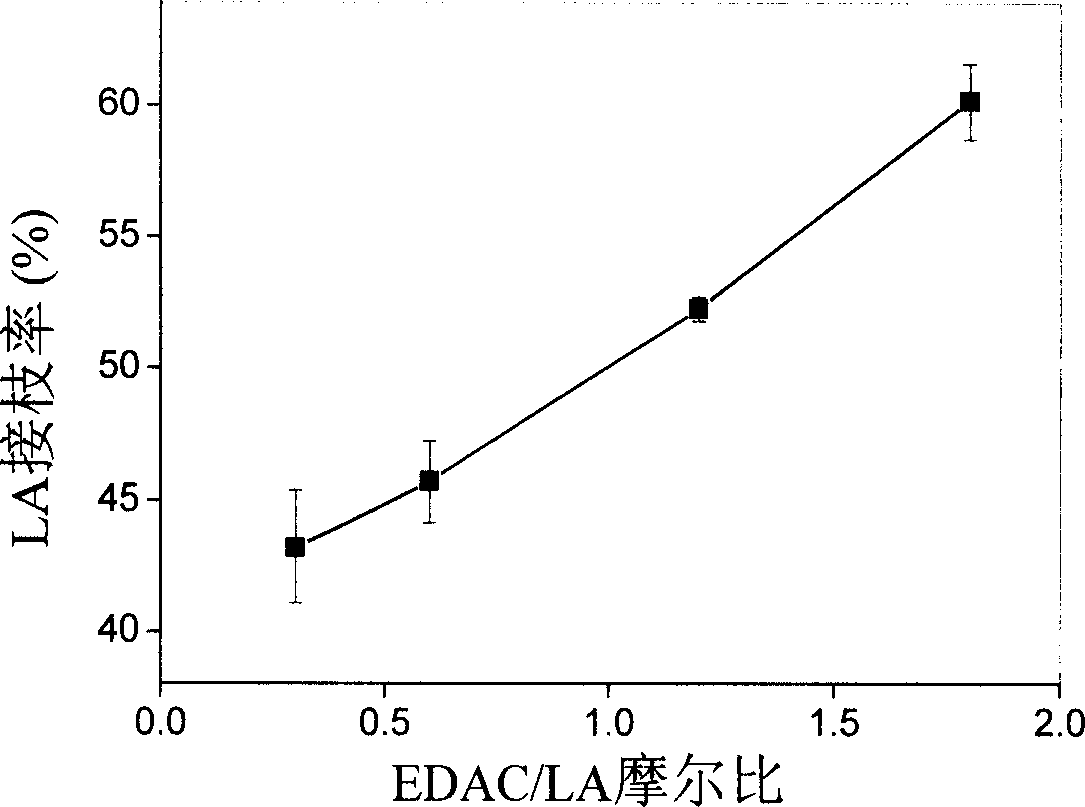

[0028] 400 mg of CM obtained in Example 1 with a grafted MA amount of about 23% was dissolved in 50 ml of three-distilled water containing 210 μl of LA (0.2 mmol), and 115 mg of EDAC (0.06 mmol) was added after complete dissolution. After the reaction mixture was stirred at room temperature for 24 hours, it was placed in a dialysis bag with a cut-off molecular weight of 10,000 Da, dialyzed in a large amount of triple-distilled water at room temperature for 3 days, and the triple-distilled water was changed 2 to 3 times a day. Finally, the liquid was frozen and freeze-dried to obtain MA and LA grafted chitosan (CML). The yield of CML is greater than 90%, and the amount of LA grafting is about 43.2%, see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic modulus of elasticity | aaaaa | aaaaa |

| Dynamic modulus of elasticity | aaaaa | aaaaa |

| Dynamic modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com