High elasticity and high strengh steel and its producing method

A technology of high-strength steel and manufacturing method, applied in the field of high-elasticity, high-strength steel and its manufacturing, can solve the problems of easy cracking, high price, enhanced self-hardening and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

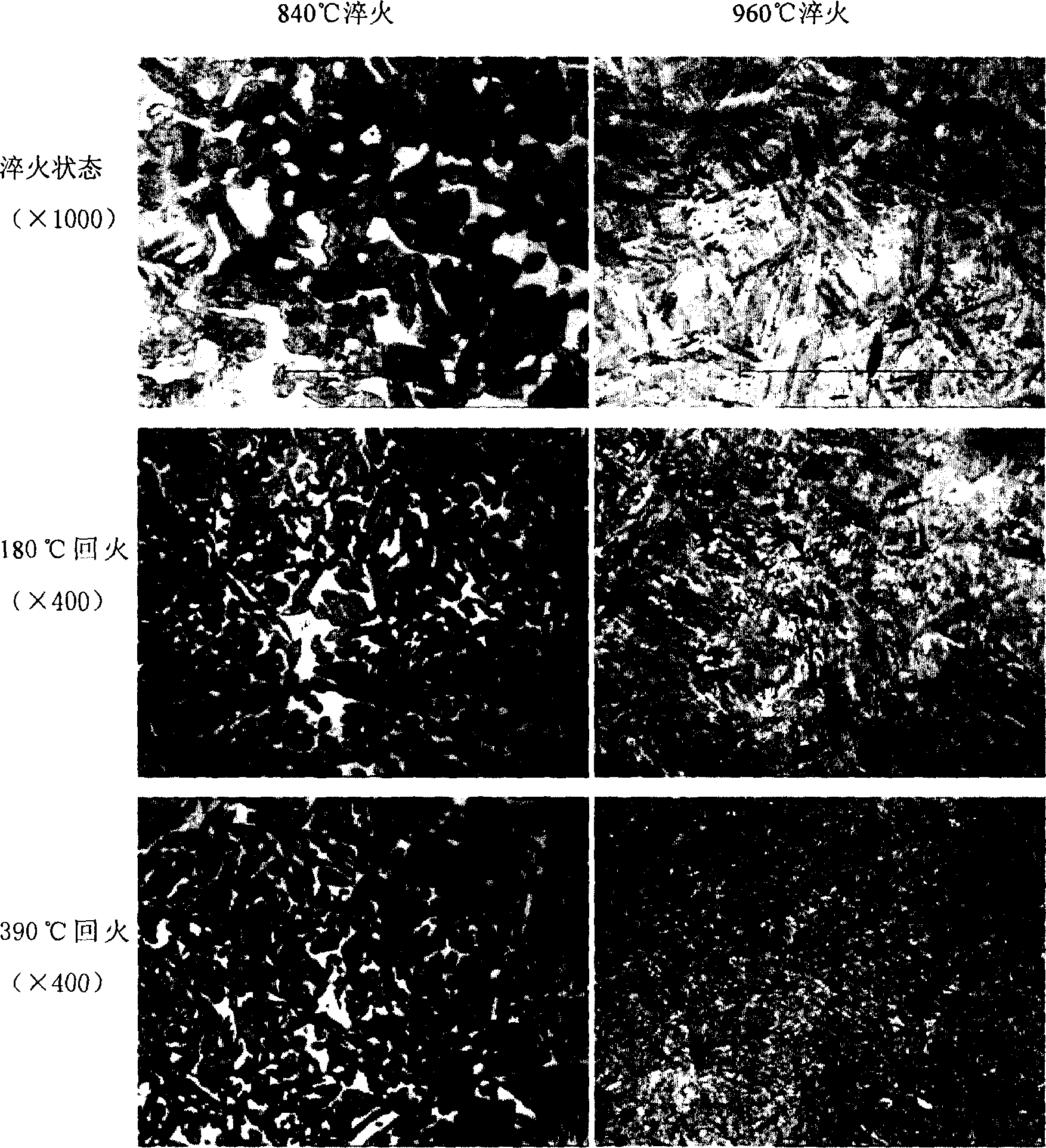

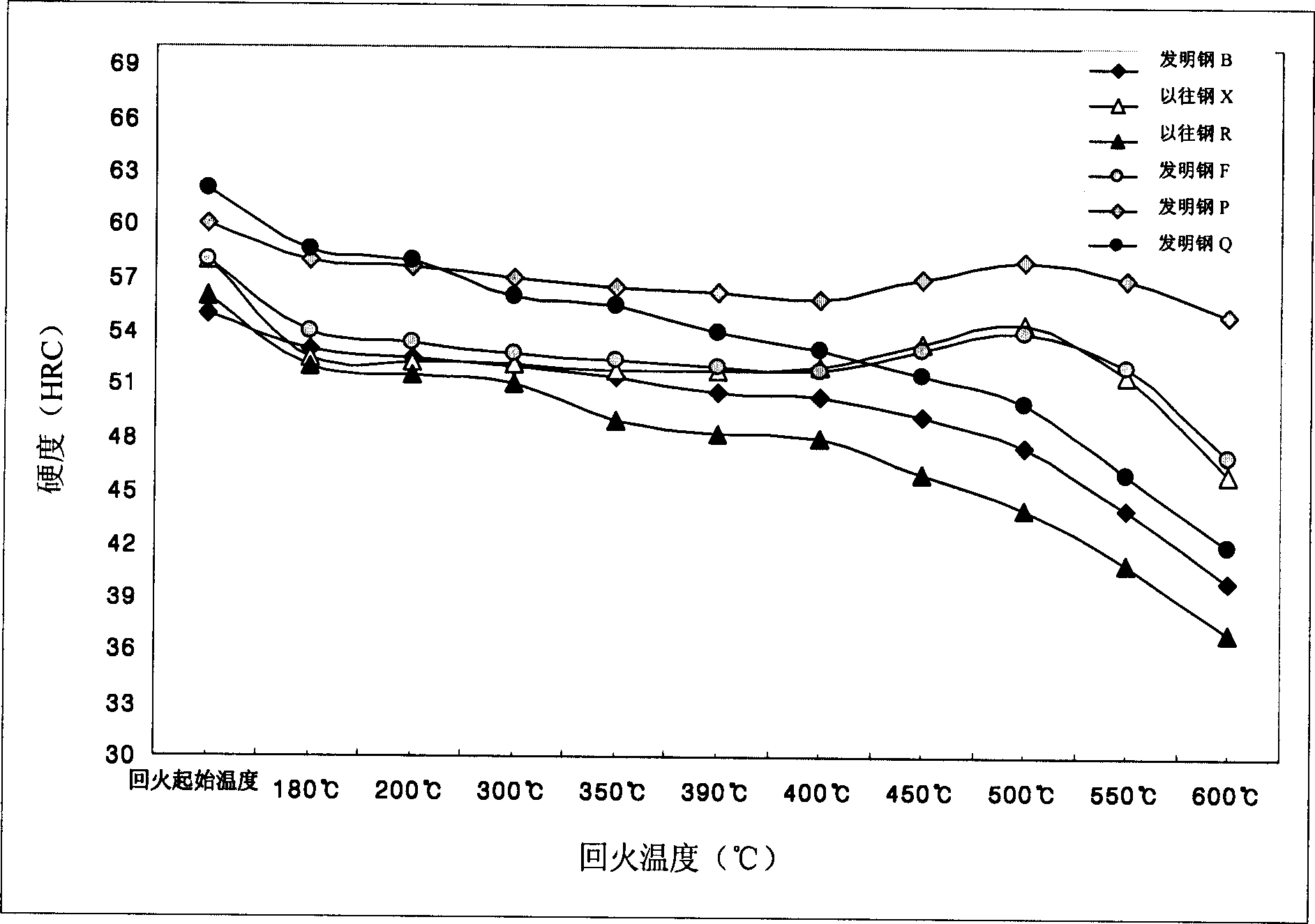

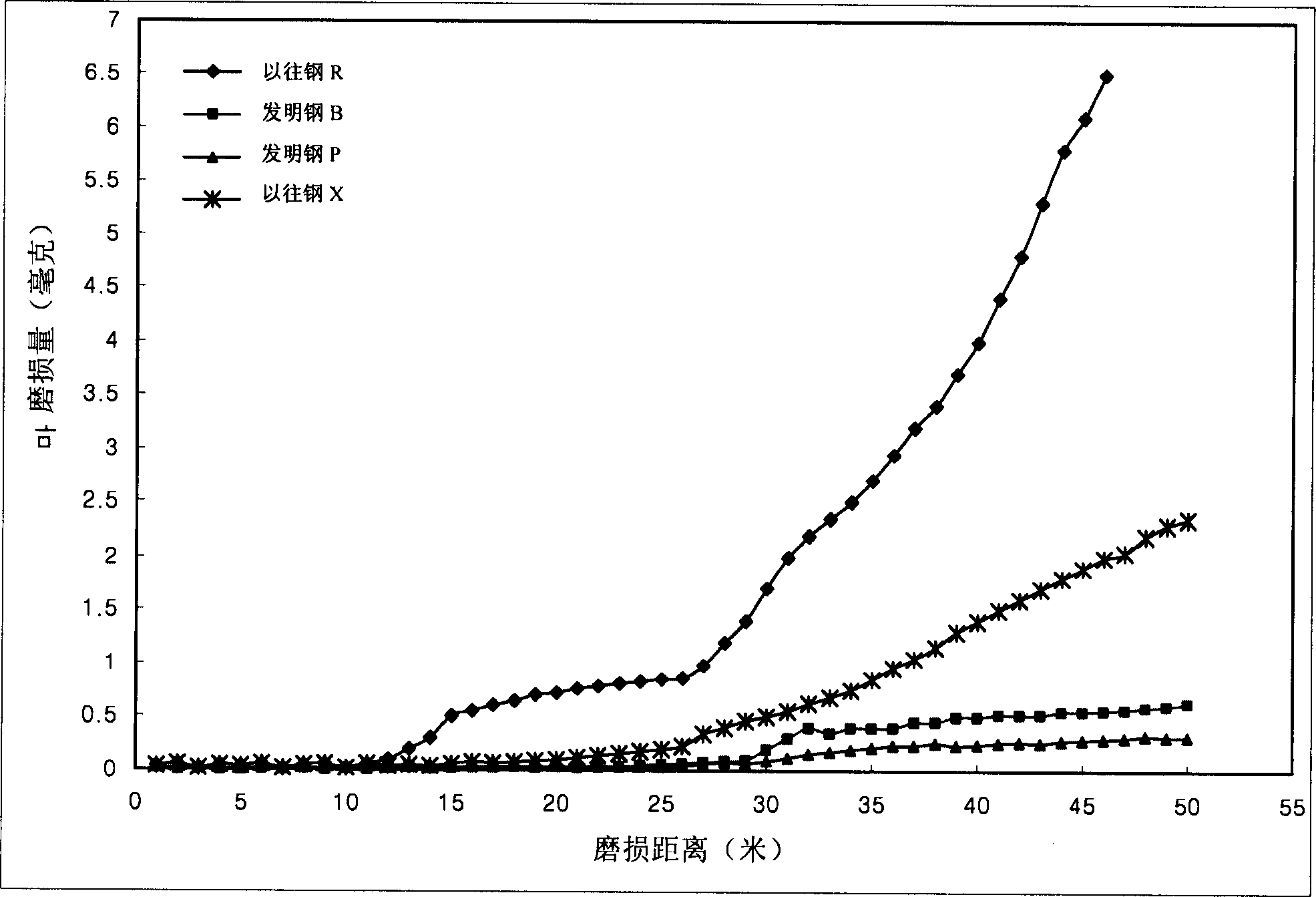

[0074] Table 1 shows the chemical composition of the invention steel of the present invention and the conventional steel of the prior art.

[0075] Invention steels A, B, C, D, E, and F are molten steels obtained by mixing and melting pure iron and scrap iron in a 60-ton electric furnace, refining and vacuum degassing, while invention steels G, H, I, J, K, L, M, N, O, P, Q Melt pure iron and scrap iron in a 3-ton electric furnace and refine them to obtain molten steel.

[0076] Inventive steels B, C, G, L, M, and N contain: 0.26-0.36% by weight of C, 1.6-2.2% by weight of Si, 0.5-1.0% by weight of Mn, 1.4-2.4% by weight of Cr, 0.01- 0.05% by weight of Ni, 0.01-0.4% by weight of Mo, 0.005-0.04% by weight of Al, 0.05-0.1% by weight of V, 0.0025-0.02% by weight of N, 0.01-0.1% by weight of Nb, 0.0005-0.01% by weight % Ca, the remainder being Fe and unavoidable impurities.

[0077] Invention steels A and E are made of molten steel with the above components and composition ranges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com