Process for preparing magnetic Czochralski silicon monocrystal

A magnetic field Czochralski, silicon single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of vortex defect oxygen content, uneven radial distribution of resistivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

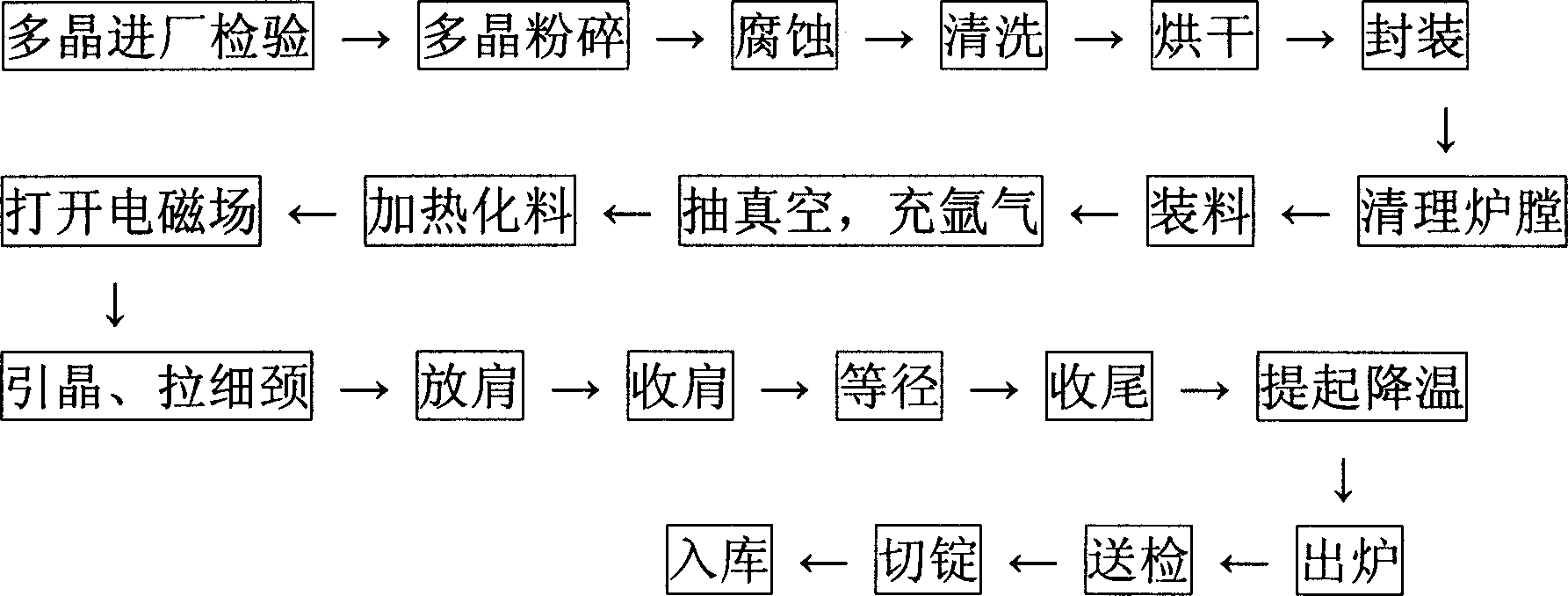

[0007] refer to figure 1 , MCZ (magnetic field Czochralski method) silicon single crystal process is: polycrystalline incoming inspection → polycrystalline crushing → corrosion → cleaning → drying → packaging → cleaning furnace → charging → vacuuming, filling with argon → heating Material → turn on the electromagnetic field → seeding, neck thinning → shoulder release → shoulder collection → equal diameter → finishing → lifting to cool down → release from the furnace → inspection → ingot cutting → storage. The above-mentioned technical solution disclosed by the present invention is the opening of the electromagnetic field and the narrowing process in the process flow, and other processes are the same as the ordinary Czochralski method, and will not be described here.

[0008] Analysis of oxygen content of MCZ silicon single crystal: The oxygen content of MCZ silicon single crystal and CZ (common Czochralski method) silicon single crystal has obvious changes, and the oxygen cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com