Biodegradation mulching film punching machine

A biodegradable, punching machine technology, applied in metal processing and other directions, can solve the problems of reduced work efficiency, poor tensioning effect, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

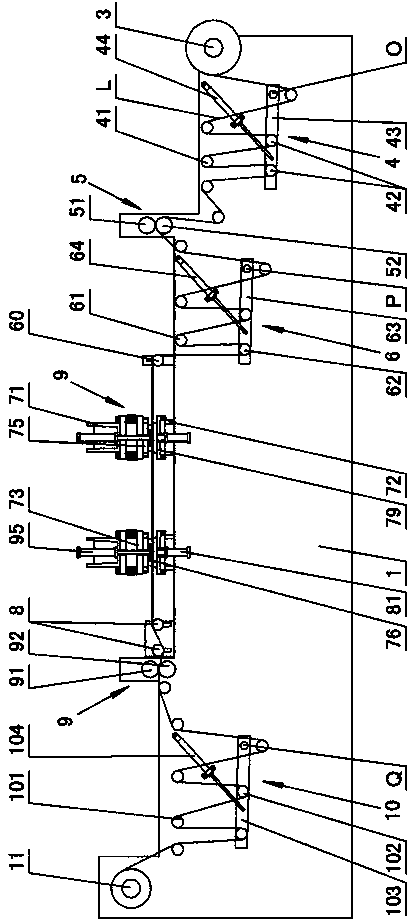

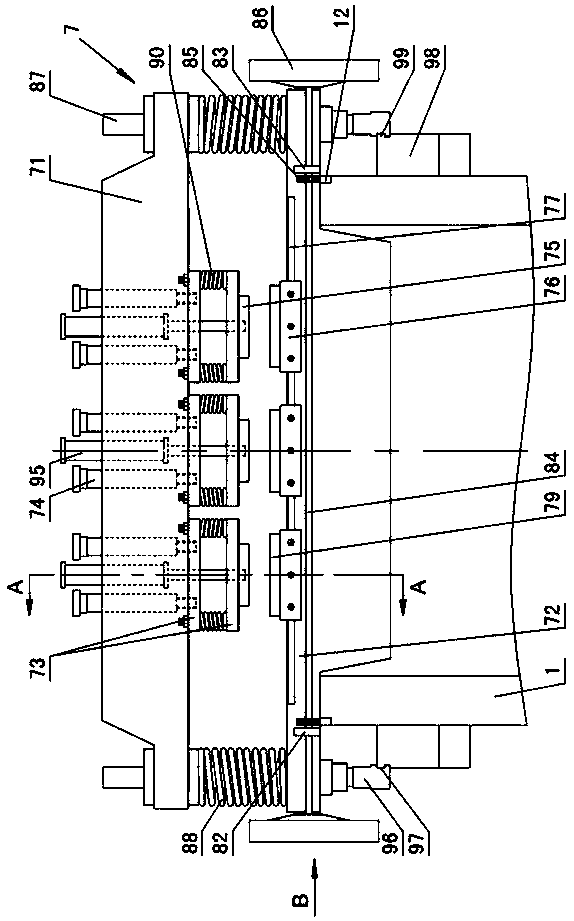

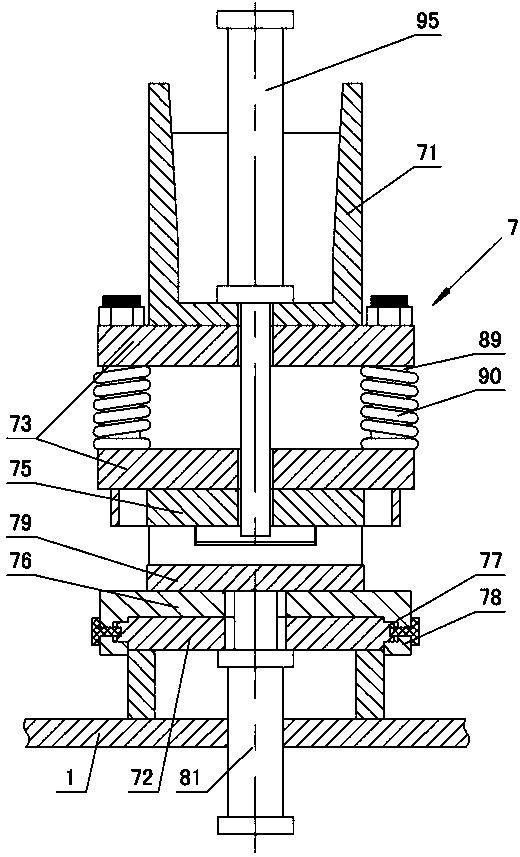

[0014] The invention relates to a biodegradable film punching machine, such as figure 1 — Figure 7As shown, it is characterized in that the punching machine includes a frame 1, on which a feed roller 3, a first feeding tension roller group 4, and a front adjustable pinch roller 5 are sequentially arranged from feeding to discharging. , feed the second tension roller group 6, feed guide roller 60, punching mechanism 7, discharge guide roller 8, post-adjustable pinch roller 9, output tension roller group 10 and coil material roller 11, the described The winding roll is driven by power, and the first tension roller group 4 for feeding includes the first upper tension roller 41 for feeding and the first lower tension roller 42 for feeding. The total number of rollers is 6-12, and the angle θ between the connection line L of the first upper and lower tension rollers and the center line I of the feeding first is 10°-18°. The rollers 41 are directly fixed on the machine base 1 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com