Process for continuously casting magnesium alloy thin strip blank

A continuous casting process and magnesium alloy billet technology, which is applied in the field of casting magnesium alloy thin strips by radial and vertical twin-roll continuous casting machines, can solve the problem of the upper and lower surface quality of the cast strip, the uneven internal structure, and the cooling speed of magnesium alloy thin strip blanks Slow solidification, long cooling time of the solidified shell, etc., to achieve uniform internal structure, good surface quality, and increased nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw material of the magnesium alloy is AZ31B, and its chemical composition is shown in Table 1.

[0033] Grade

Al

Zn

mn

Fe

Si

Mg

AZ31B

3.0

0.95

0.15

0.001

0.08

95.819

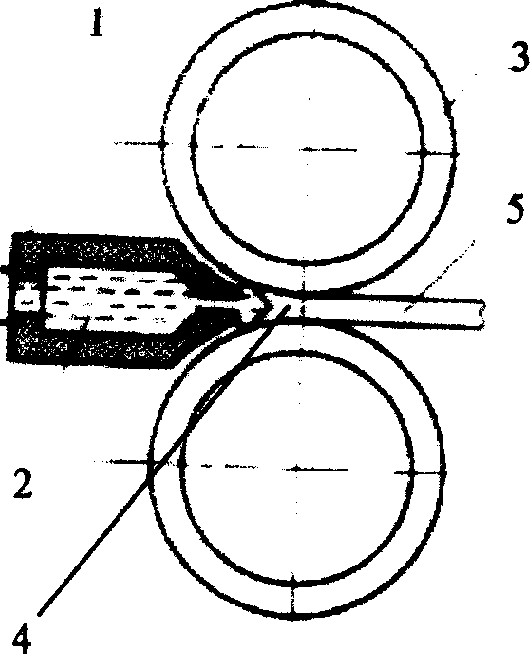

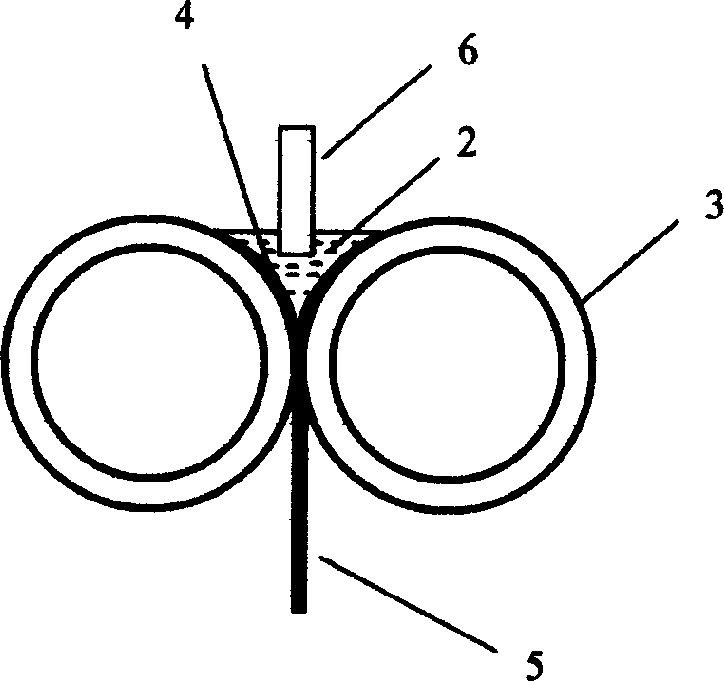

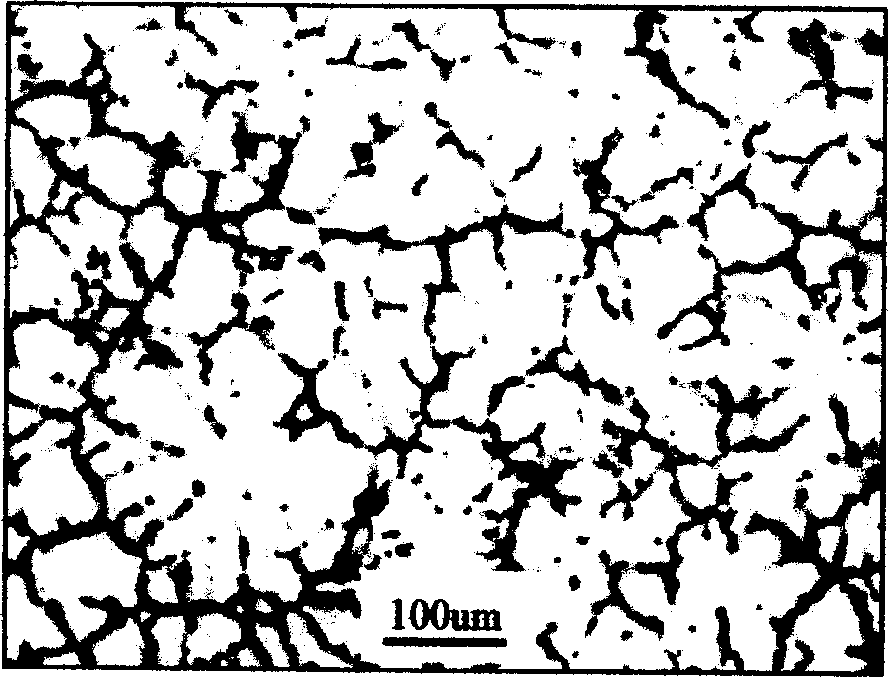

[0034] see Figure 4. First, preheat the magnesium alloy billet at 200°C for 15 minutes, add a small amount of melting flux into the resistance melting crucible furnace, and when the inner wall of the crucible is red and bright, put the preheated magnesium alloy billet into the crucible, melt it and smelt it with magnesium alloy The usual method for slag removal is to let the magnesium alloy billet stand for 10 minutes after melting. Then transfer the melt to the tundish and keep it warm for 15 minutes, and start casting when the temperature is 650°C. The preheating temperature of the side sealing system before casting is 400°C. During casting, the melt enters the equal-diameter vertical twin-roll continuous casti...

Embodiment 2

[0037] The magnesium alloy raw material, smelting method and casting roll size are the same as in Example 1.

[0038] Transfer the magnesium alloy melt to the tundish and keep it warm for 15 minutes. Casting starts when the temperature is 660°C. The preheating temperature of the side sealing system before casting is 400°C. During casting, the melt enters the equal-diameter vertical double rollers through the flow distribution device The continuous casting machine casts in a submerged manner, keeps the molten pool height at 100mm, and its casting speed at 40m / min. After leaving the casting roll, the thin strip blank enters the pinch roll, and the magnesium alloy thin strip blank with a thickness of 2.5mm and a width of 150mm is obtained with good surface quality and uniform and fine internal structure. CO is used in the casting process 2 +SF 6 Mixed gas protection.

Embodiment 3

[0040] The magnesium alloy raw material, smelting method and casting roll size are the same as in Example 1.

[0041] Transfer the magnesium alloy melt into the tundish and let it stand for 20 minutes. Casting starts when the temperature is 670°C. The preheating temperature of the side sealing system before casting is 430°C. During casting, the melt enters the equal-diameter vertical double rolls through the melt distribution device The continuous casting machine casts in a submerged manner, keeps the molten pool height at 100mm, and its casting speed at 50m / min. After leaving the casting roll, the thin strip blank enters the pinch roll, and the magnesium alloy thin strip blank with a thickness of 2.0mm and a width of 150mm is obtained with good surface quality and uniform and fine internal structure. CO is used in the casting process 2 +SF 6 Mixed gas protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com