Micro miniature self locking type 1X2 mechanical optical switch

A self-locking, ultra-miniature technology, used in optics, nonlinear optics, optical waveguide coupling, etc., can solve the problems that the relay does not have the function of keeping the state after power failure, the overall packaging of the device is difficult, and the repeatability is poor. Achieve the effect of novel structure, low loss and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

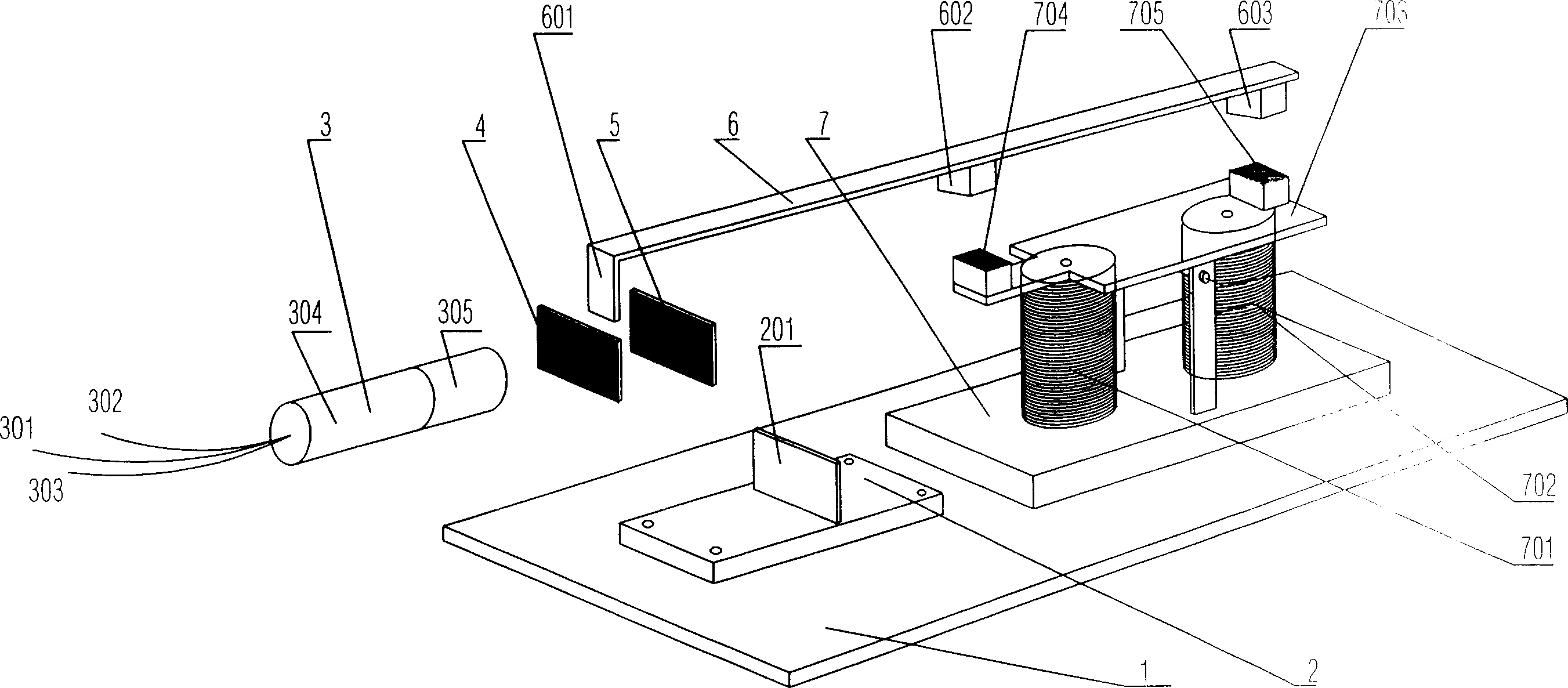

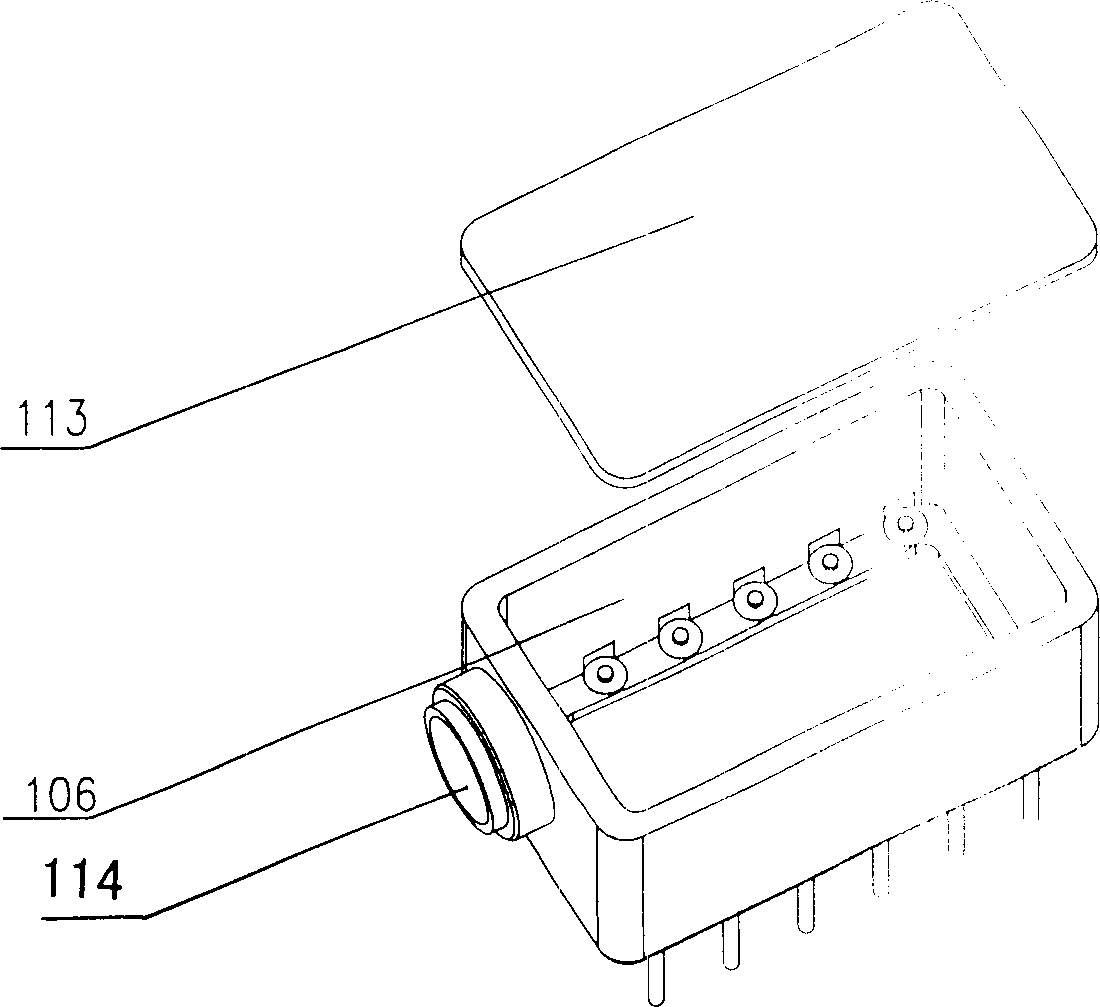

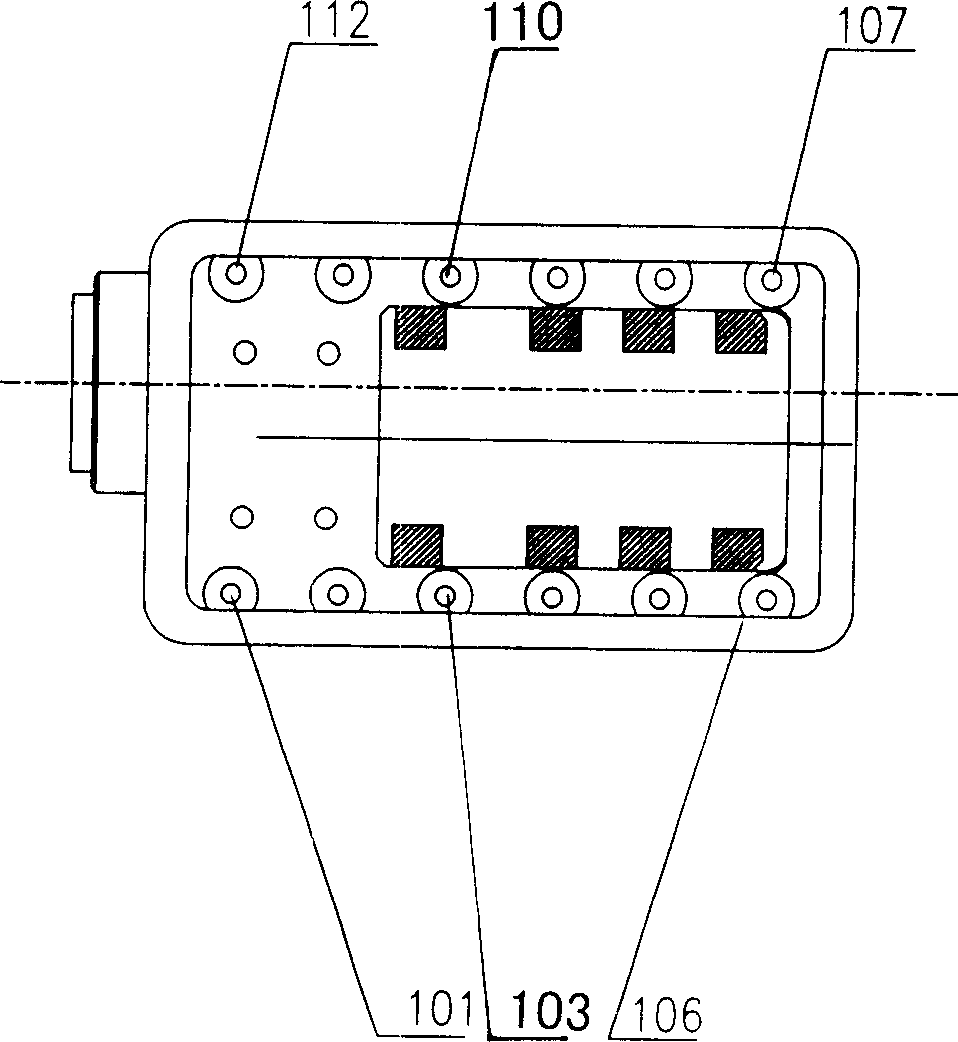

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a base 1 with an upper cover 113, a small platform 2 is fixed on the base 1, and a fixed reflector 5 coated with a high-reflection film on one side is fixed on the baffle 201 of the small platform 2 , The three-fiber collimator 3 is fixed and bonded in the circular opening 114 on the base 1, and the micro relay 7 is fixed and bonded in the base. The cantilever beam 6 and the movable mirror 4 are fixed on the relay 7 One side is coated with a high-reflection film, and the other side is fixed on the baffle 601 of the cantilever 6; the three optical fibers 301, 302, and 303 of the three-fiber collimator 3 are fixed in the same glass tube 304, and the glass The end plane of the tube 304 is coated with an anti-reflection coating, and the plane of the glass tube 304 is fixedly bonded to the lens 305. The three optical fibers 301, 302, and 303 of the three-fiber collimator 3 are arranged in a straight li...

Embodiment 2

[0017] See figure 1 , figure 2 , image 3 with Figure 5 , The three optical fibers in the three-fiber collimator 3 described in Embodiment 1 are arranged in an equilateral triangle, and the rest remain unchanged.

[0018] The typical test results are:

[0019] Dimensions: 16.8mm×10mm×8mm

[0020] Performance index: wavelength range: 1260~1600nm;

[0021] Insertion loss: 0.3dB typical, 0.4dB maximum;

[0022] Polarization dependence: typical 0.05dB; crosstalk: <60dB;

[0023] Switching time: 2~3ms; PMD: 55dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com