Coating layer of Nano composite diamond, and preparation method

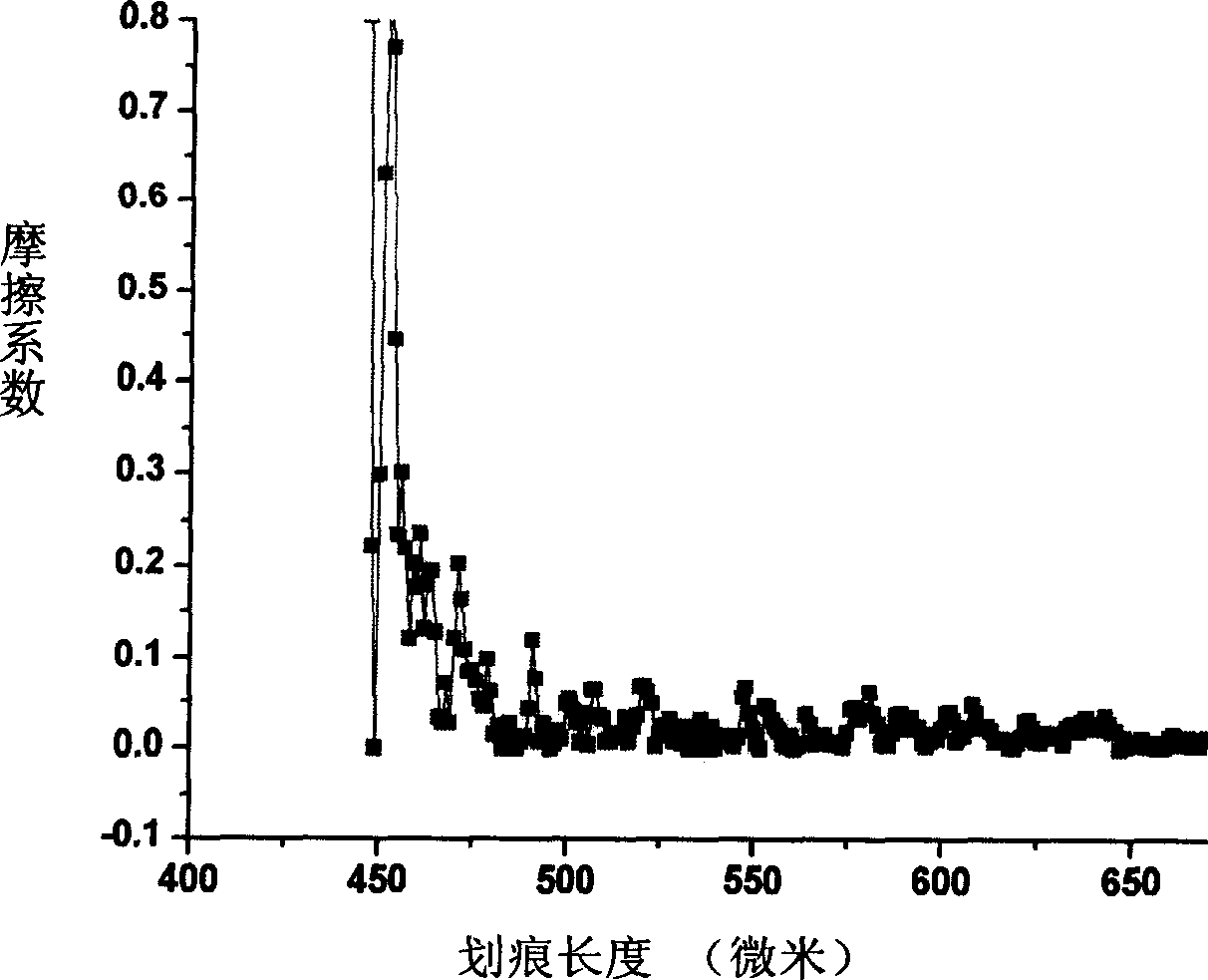

A diamond coating and nano-composite technology, applied in metal material coating process, coating, device for coating liquid on the surface, etc., can solve the problems of few products, little progress, etc., achieve short time and good adhesion , the effect of low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

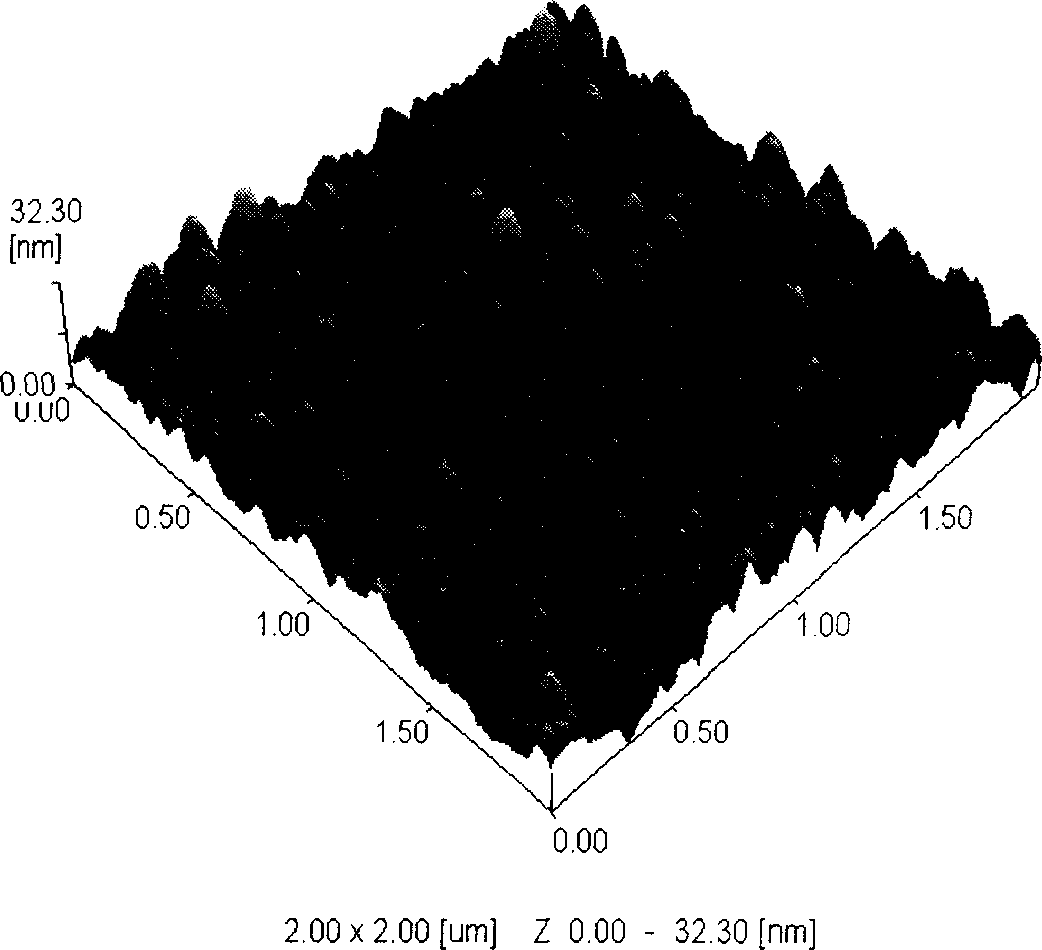

[0023] The structure of the nanocomposite diamond-like coating includes three layers. The bottom layer is pure metal Ti with a thickness of 100-200 nanometers to increase the bonding force between the coating and different substrate materials. The middle layer is a mixed layer of Ti and DLC for pure Metal to DLC provides a buffer layer that increases adhesion between Ti and DLC. On the top of the buffer layer is a Ti-doped nano-composite DLC coating, and the size of the Ti grains is below 10 nanometers. Due to the nanocrystalline-amorphous strengthening effect, under the condition of low coating stress, it has high hardness while maintaining good lubricating performance, and its hardness can reach 22GPa.

[0024] Clamp the cleaned workpiece on the workpiece rack and start vacuuming. When the vacuum degree is higher than 5×10 -3 Pa, start heating and degassing, the temperature is controlled at 150-200°C, the workpiece holder is kept at 4rpm, when the vacuum degree is 5×10 -3 ...

Embodiment 2

[0026] The structure of the nanocomposite diamond-like coating includes three layers, the bottom layer is pure metal Cr with a thickness of 200 nm, and the middle layer is a mixed layer of Cr and DLC with a thickness of 50 nm. The top layer is a Cr-doped nanocomposite DLC coating with a thickness of 200 nanometers, and the size of Cr crystal grains is below 10 nanometers.

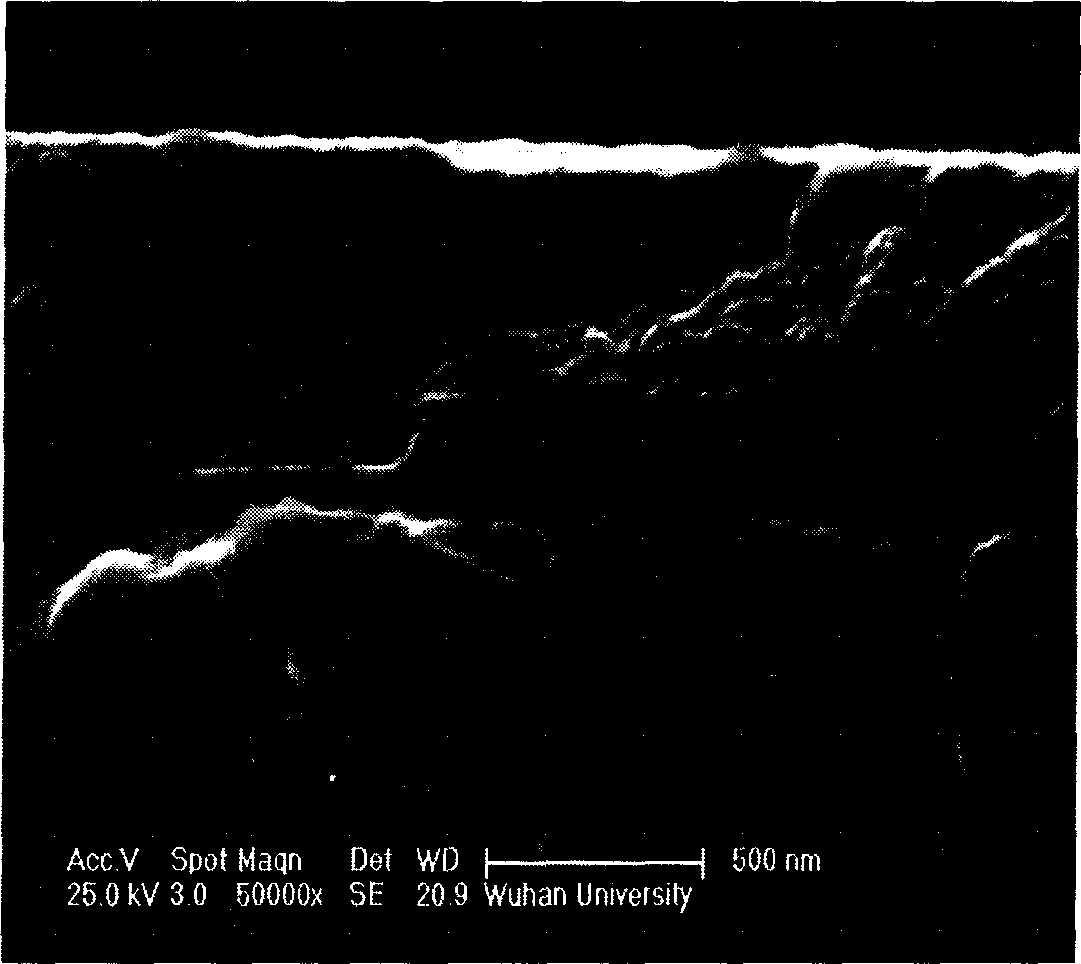

[0027] First, glow clean the workpiece at 150-200°C in an argon environment; after glow cleaning, deposit 200nm thick metal Cr at 0.4-0.8Pa; then deposit 200nm Cr at 150-200°C and diamond-like mixed layer; when the mixed layer is deposited, deposit 500nm transition metal-doped nanocomposite under the conditions of 80-100°C, -80 to -100V bias, and Cr content of 4-10at.%. Diamond coating; natural cooling to obtain nanocomposite diamond-like coating. The SEM image of the coating surface shows that the coating surface has no obvious defects and is very smooth. It shows that the use of intermediate frequency s...

Embodiment 3

[0029] The structure of the nanocomposite diamond-like carbon coating includes three layers, the bottom layer is a transition metal Cu or V or Al with a thickness of 100 nanometers, and the middle layer is a mixed layer of transition metals and DLC with a thickness of 200 nanometers. The top layer is a Cr-doped nanocomposite DLC coating with a thickness of 2800 nanometers, and the size of transition metal crystal grains is below 10 nanometers.

[0030] The preparation method is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com