Process for preparing bentonite based sodium with high expension performance by drying method

A sodium-based bentonite, high-expansion technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of long process route, difficulty in realizing large-scale production, and high production cost, and achieve simple production technology and equipment. The effect of strong adaptability and less production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 60g Anji bentonite powder, 6g urea powder and 1.2g Na 2 CO 3 After the powder is mixed evenly, put it in an oven and keep the temperature between 85-120°C for 3 hours. According to the bentonite performance test method (JC / T 593-1995), the expansion ratio and colloid value are tested, and the result is: expansion ratio 41mL / g , Gum price 500mL / 15g.

Embodiment 2

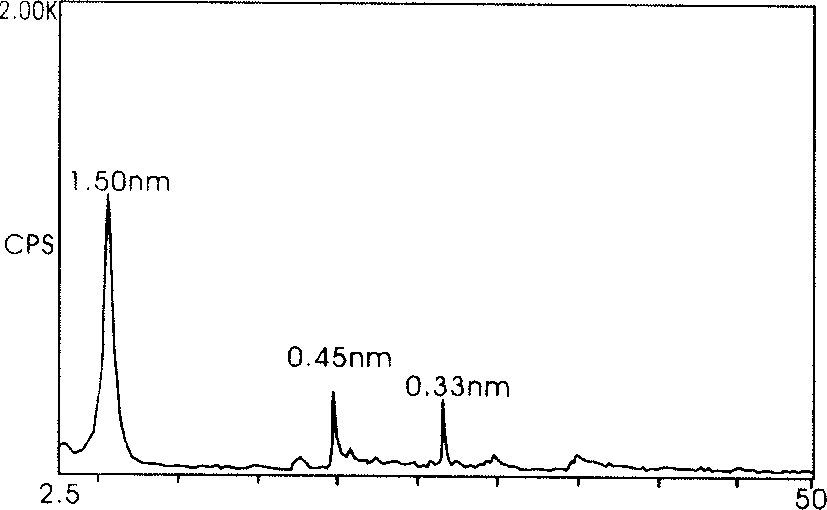

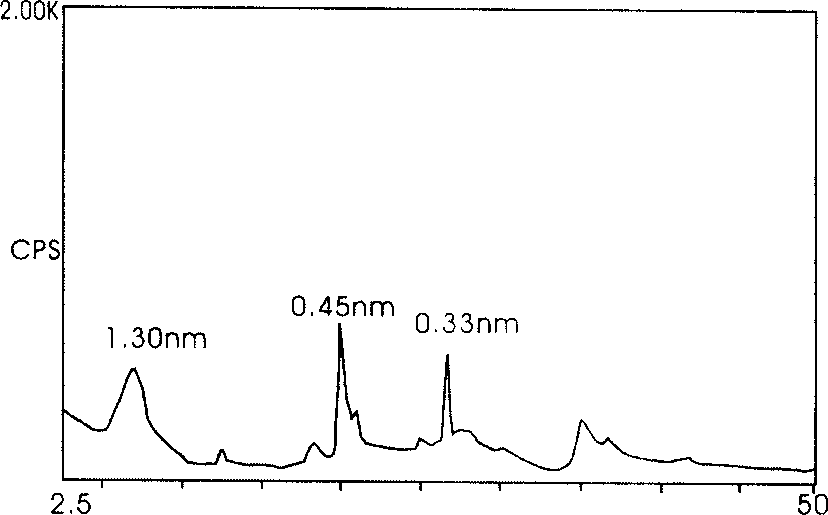

[0051] 100g Anji bentonite powder, 10g urea powder and 3g Na 2 CO 3 After the powder is mixed evenly, put it in an oven, keep the temperature at 85-120°C for 3 hours, and check the expansion ratio and colloid value according to the bentonite performance testing method (JC / T 593-1995), and the result is: expansion ratio 56mL / g , Gum price 500mL / 15g. X-ray diffraction analysis (XRD) was used to detect the structural changes of Anji bentonite before and after treatment. Anji calcium-based bentonite see attached figure 1 , the inter-network spacing d value of its montmorillonite (001) face is 1.50nm; The XRD analysis of the high-expansibility sodium-bentonite after the process of this method is shown in the appendix figure 2 , the grid spacing d value of the montmorillonite (001) surface is reduced to 1.30nm.

Embodiment 3

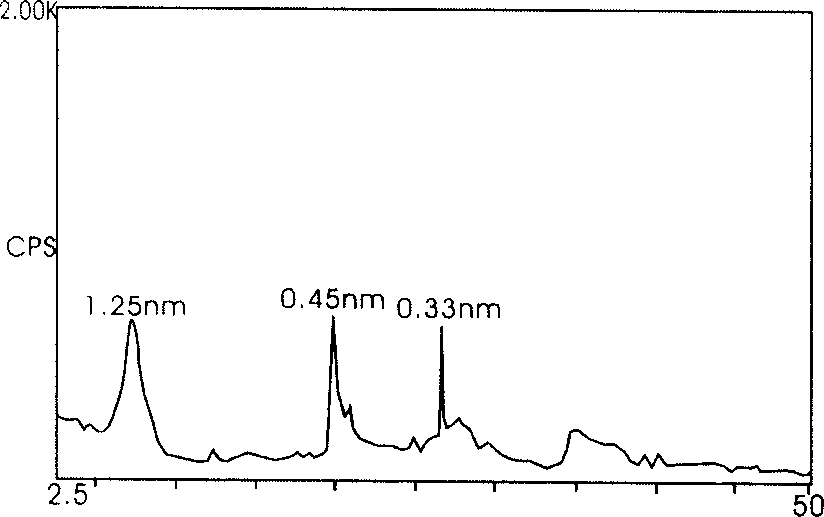

[0053] 1kg Anji bentonite powder with a moisture content of 11.5%, 50g urea powder and 40g Na 2 CO 3 After the powder is mixed evenly, put it in an oven, keep the temperature between 85-120°C for 3 hours, and check the expansion ratio and colloid value according to the bentonite performance testing method (JC / T 593-1995), and the result is: expansion ratio 80mL / g , Gum price 500mL / 15g. Utilize X-ray diffraction analysis (XRD) to detect the high expansibility sodium bentonite after this method is processed, and the face net spacing d value of its montmorillonite (001) face is reduced to 1.25nm by 1.50nm before processing, see appendix image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com