Ultraviolet ray solidification cation type etching glue for nano embessing

A nano-imprinting, cationic technology, applied in the field of etchant, can solve the problems of bubble curing strength, poor reproduction accuracy, insufficient extrusion, etc., to achieve good film formation stability, ensure etching accuracy, Guarantee the effect of imprinting and replicating accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

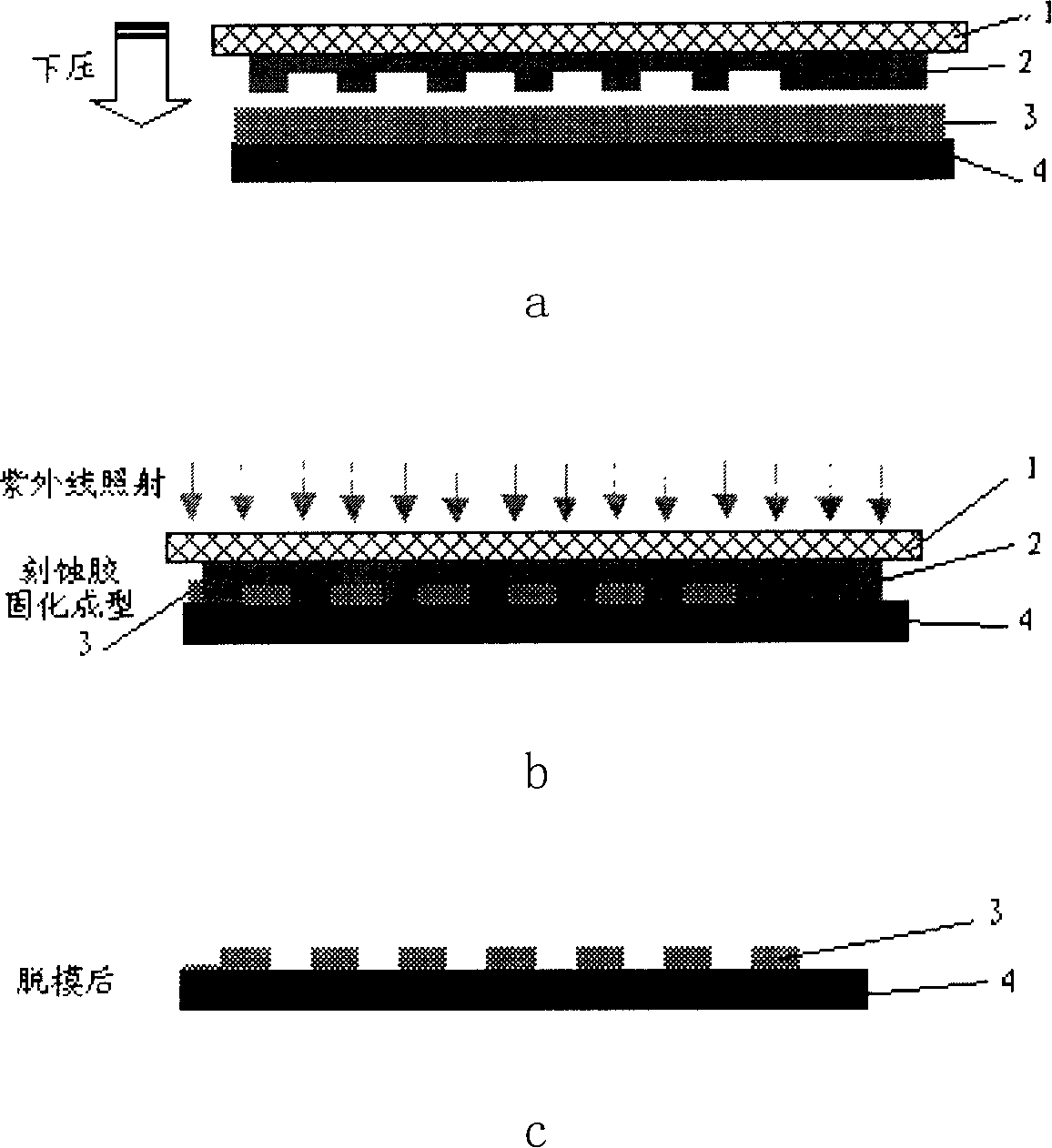

Method used

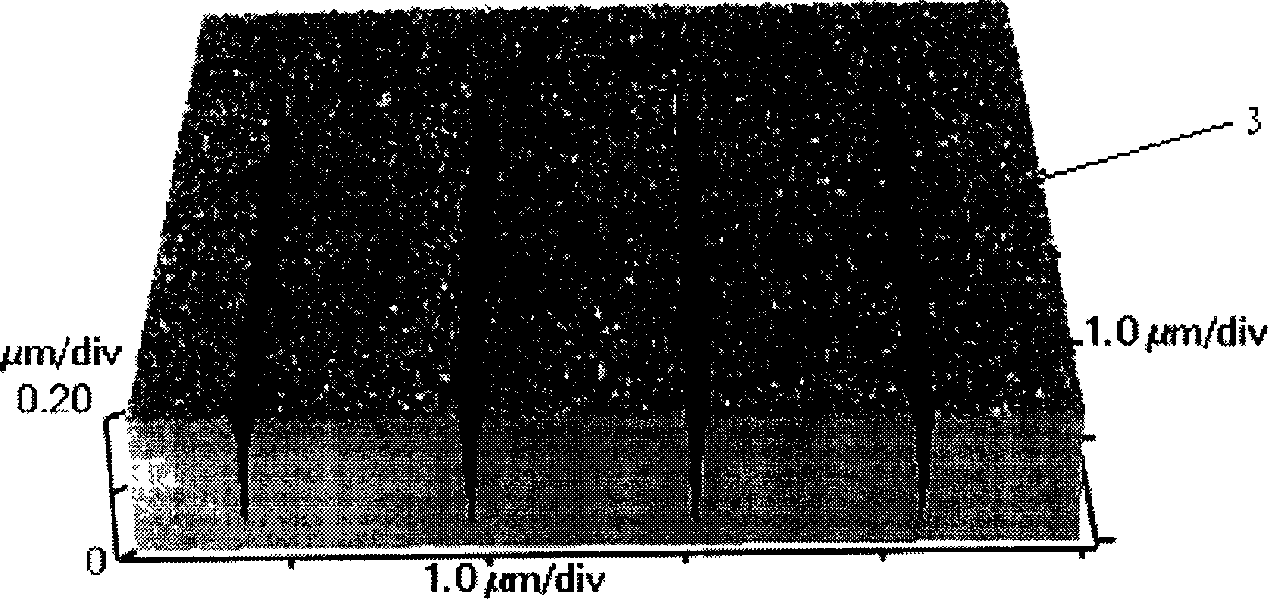

Image

Examples

Embodiment 1

[0043] First choose the mixture of diaryliodonium phosphate and triarylsulfonium hexafluoroantimonate as photoinitiator, the weight of photoinitiator is 3% of total etching glue weight, wherein diaryliodonium phosphate accounts for 70% of photoinitiator, triarylsulfonium hexafluoroantimonate accounts for 30% of photoinitiator, gets the triethylene glycol divinyl ether of gross weight 15%, photoinitiator diaryliodonium phosphate is in Dissolve in triethylene glycol divinyl ether at 50°C, add triarylsulfonium hexafluoroantimonate after cooling to room temperature and stir to form a homogeneous solution A; Cyclohexanoic acid-3', 4'-epoxycyclohexyl methyl ester, 15% linear polydimethylsiloxane, 10% polycaprolactone diol were added to the device and stirred at high speed, and stirred and mixed for 2 hours After forming a uniform liquid B, then add solution A, and then mix and stir for 2 hours to obtain a uniform liquid C, then add a total weight ratio of 0.4% organic alcohol defoam...

Embodiment 2

[0045] Firstly, the mixture of 1% diaryliodonium phosphate and 1% triarylsulfonium hexafluoroarsenate is selected as the photoinitiator in the total weight ratio, and the photoinitiator diaryliodonium phosphate is heated at 50° C. Dissolve with 1,4-cyclohexyldimethanol divinyl ether, the amount of 1,4-cyclohexyldimethanol divinyl ether is 10% of the total weight ratio, after dissolving, cool to room temperature and add triarylsulfonium hexafluoroarsenic Acid acid was stirred to form a homogeneous solution A; the total weight ratio was respectively 40% of 3,4-epoxycyclohexyl carboxylic acid-3', 4'-epoxycyclohexyl methyl ester and 20% of bis-(3 , the mixture of 4-epoxycyclohexyl)-adipate and 20% polycaprolactone trihydric alcohol were added to the device and stirred at a high speed, and after stirring and mixing for 2 hours, a uniform liquid B was formed, and then solution A was added, and mixed again Stir for 2 hours to obtain a uniform liquid C, then add polyether alkyl co-mod...

Embodiment 3

[0047] First select the mixture of 0.2% diaryl iodonium phosphate and 0.8% triaryl sulfonium hexafluoroantimonate as the photoinitiator in the total weight ratio, and make the diaryl iodonium phosphate photoinitiator at 50°C Dissolve with the mixed solution of glycerol carbonate propenyl ether and dodecyl vinyl ether, the mixed solution of glycerol carbonate propenyl ether and dodecyl vinyl ether is 40% of the total weight ratio, after dissolving, cool to Stir at room temperature and add triarylsulfonium hexafluoroantimonate to form a homogeneous solution A; 3,4-epoxy-6-methyl-cyclohexylcarboxylic acid-3', 4' with a total weight ratio of 10% -Epoxy-6'-methylcyclohexyl methyl ester and 30% bulk polydimethylsiloxane, 15% 1,2-epoxyhexadecane are placed in the device and stirred at high speed, and mixed After 2 hours, a homogeneous liquid B is formed, then add solution A, and mix and stir for 2 hours to obtain a homogeneous liquid C, then add an auxiliary agent with a total weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com