Method for synthesizing lithium ion cell positive cell polar material rotary furnace

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of calcination and synthesis of lithium-ion battery positive electrode materials in a rotary furnace, which can solve the problems of prolonging high-temperature treatment time, large dust pollution, and large energy waste, and achieve shortened high-temperature treatment time and reduced dust pollution , The effect of material waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

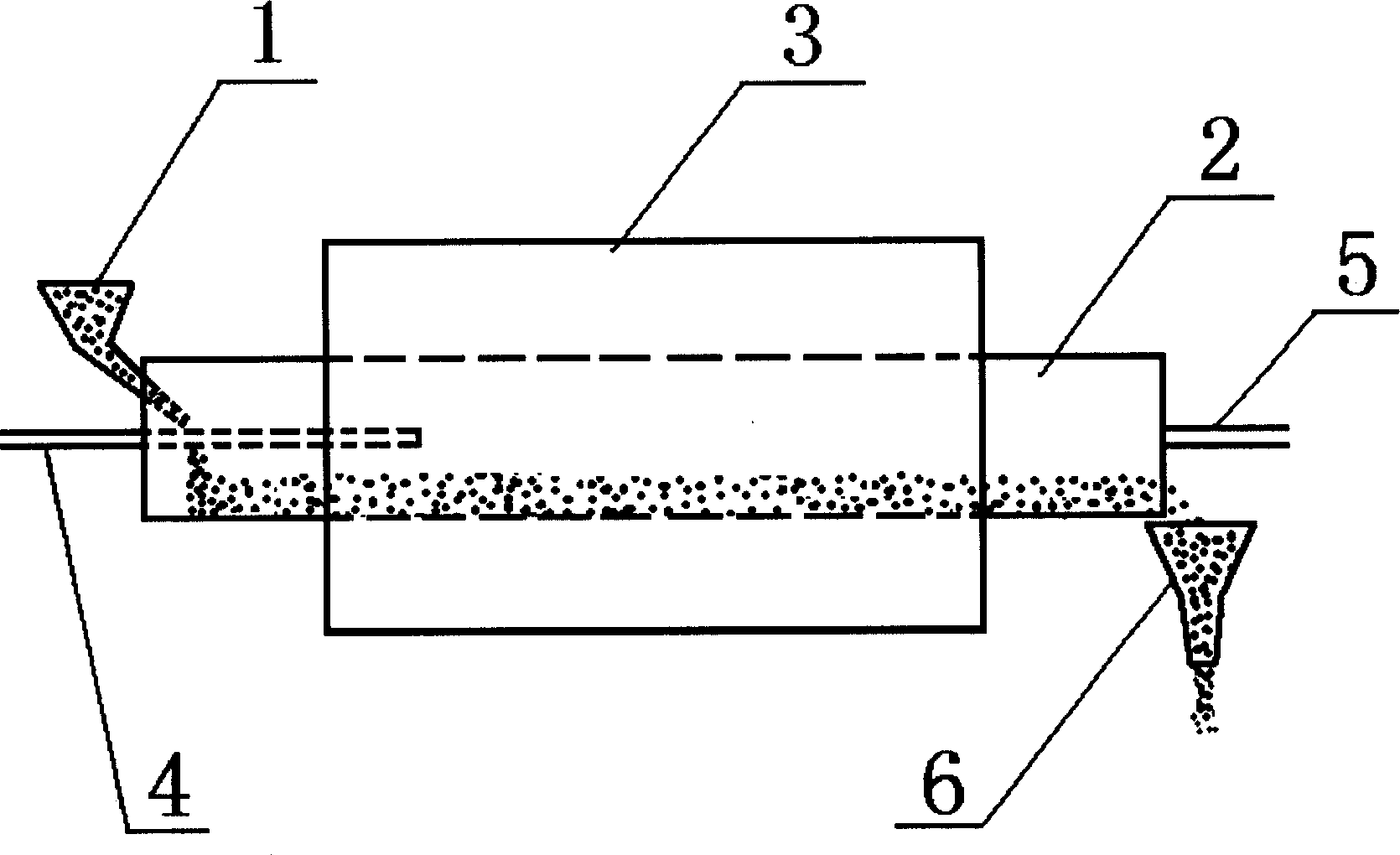

Image

Examples

Embodiment 1

[0040] Lithium cobalt oxide (LiCoO) is a cathode material for lithium-ion batteries. 2 ) preparation: raw material Co 3 o 4 with LiOH·H 2 O is evenly mixed with a molar ratio of Li:Co=1.02:1, and then moved into a rotary furnace, the temperature in the rotary furnace is 800°C, the rotation speed is 2 rpm, the material is calcined in the rotary furnace for 30h, and taken out after cooling. The product is crushed and sieved to obtain the lithium cobaltate product. The particles of this product are uniform, the electrochemical reversible capacity is over 135mAh / g, and the cycle performance is good.

Embodiment 2

[0042] Lithium-ion battery cathode material LiCo 0.5 mn 0.4 o 2 Preparation: the raw material CH 3 COOLi and (CH 3 COO) 3 Co is dissolved in the aqueous solution at a molar ratio of Li:Co=1.03:0.5, and glycolic acid (HOCH 2 CO 2 H), slowly add ammonia water under stirring condition to adjust pH=6.5~7, add LiMn after evaporating and concentrating 2 o 4 , adding LiMn 2 o 4 After that, the mol ratio of each material is Li: Co: Mn=1.03: 0.5: 0.5, continue to stir, filter, dry, then move into the rotary kiln, the temperature in the rotary kiln is 800 ° C, the rotating speed is 3 revolutions per minute, the material is in the rotary kiln Internal calcination for 30h, and take out after cooling. The product is crushed and sieved to obtain LiCo 0.5 mn 0.5 o 2 product. The particle size of the product is uniform, the electrochemical reversible capacity is over 120mAh / g, the cycle performance is good, and the high temperature performance is good.

Embodiment 3

[0044] Lithium-ion battery cathode material LiCo 0.5 Ni 0.5 o 2 Preparation: with LiOH·H 2 O. Co 3 o 4 , Ni(OH) 2 As a raw material, mix evenly according to the molar ratio Li:Ni:Co=1:0.5:0.5, and then move it into a rotary kiln. take out. The product is crushed and sieved to obtain LiCo 0.5 Ni0.5 o 2 product. Its electrochemical reversible capacity is 170mAh / g, and its cycle performance is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com