Glutamic acid capable of having high-yield glutamine

A technology of Corynebacterium glutamicum and glutamine, applied in the direction of bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

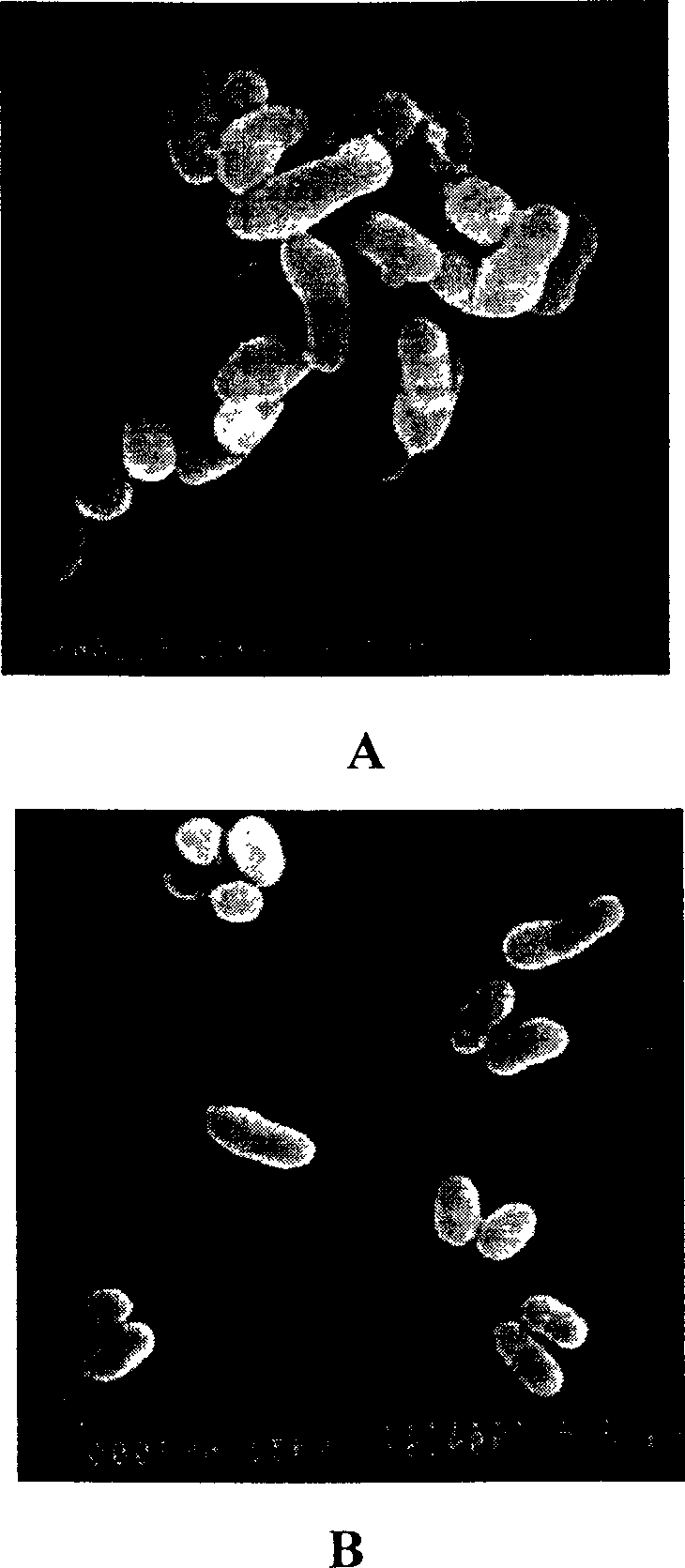

[0036] Example 1: Screening of Corynebacterium glutamicum G32CCTCC NO.M205028 strain

[0037] Add a nitrosoguanidine (NTG) solution with a final concentration of 300ug / ml to the seed medium that has been cultivated to the mid-logarithmic growth phase (pre-added glass beads), treat it with constant temperature shaking at 30°C for 30 minutes, and then take 5ml and add it to a In a sterile test tube, immediately add 0.5ml of 25% sodium thiosulfate to terminate the effect. Take an appropriate dilution (preferably 10 5 bacterium / ml) coating screening plate, the screening plate is LB medium plus sulfaguanidine (SG) and 0.5% LiCl, wrap it with paper to avoid light, and culture it upside down at 30°C for 2 to 3 days , pick a single colony for shaking tube culture, shake tube culture is carried out on a reciprocating shaker at 30°C, speed 100r / min, stroke 8cm, after 72 hours of culture, use YSI2700 biochemical analyzer to detect glutamine production, and select high-yielding strains ...

Embodiment 2

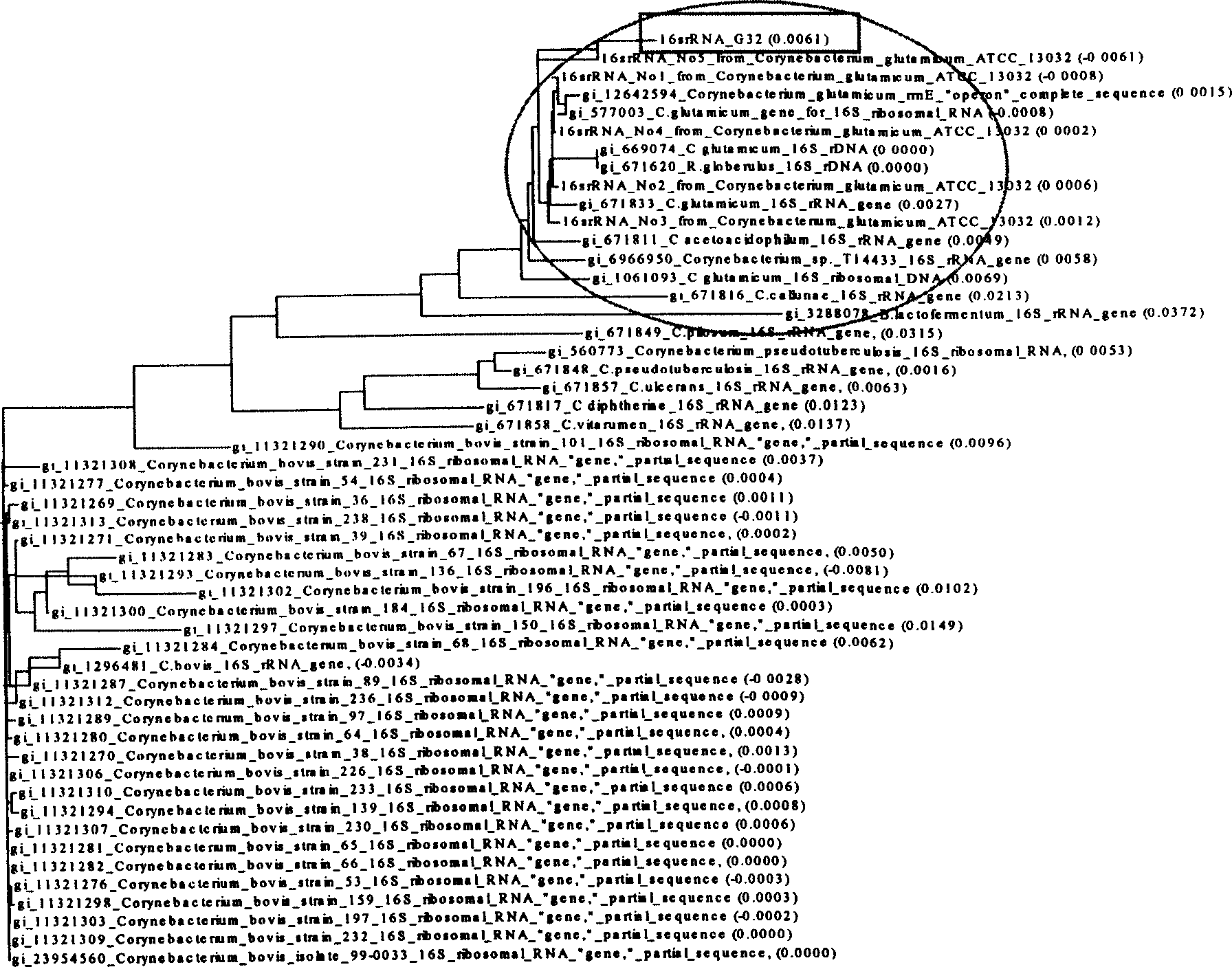

[0041] Example 2: Extraction of the 16S rDNA gene of the above Corynebacterium glutamicum G32 CCTCCNO.M205028 strain

[0042] Cultivate 5ml of bacterial culture to saturation, take 1.5ml of culture, and centrifuge at 6000g for 2 minutes; add 565μl of TE buffer to the precipitate, and the formula of TE buffer is as follows: 10mmol / L Tris (Tris), 1mmol / L ethylenediaminetetraacetic acid (EDTA), adjust the pH to 8.0 with hydrochloric acid, resuspend it by repeatedly blowing with a pipette, add 30μl of sodium dodecylsulfonate (SDS) with a mass volume ratio of 10% and 5μl 20mg / mL proteinase K, mix well, incubate at 37°C for 1 hour; add 100μl, 5mol / L NaCl, mix thoroughly, then add 80μl CTAB / NaCl solution, the formula of CTAB / NaCl solution is as follows: the mass volume ratio is Dissolve 10% cetyltriethylammonium bromide (CTAB) in 0.7mol / L NaCl, mix well, and incubate at 65°C for 10 minutes; add an equal volume of chloroform / isoamyl alcohol, mix well, Centrifuge at 12000g for 5 minut...

Embodiment 3

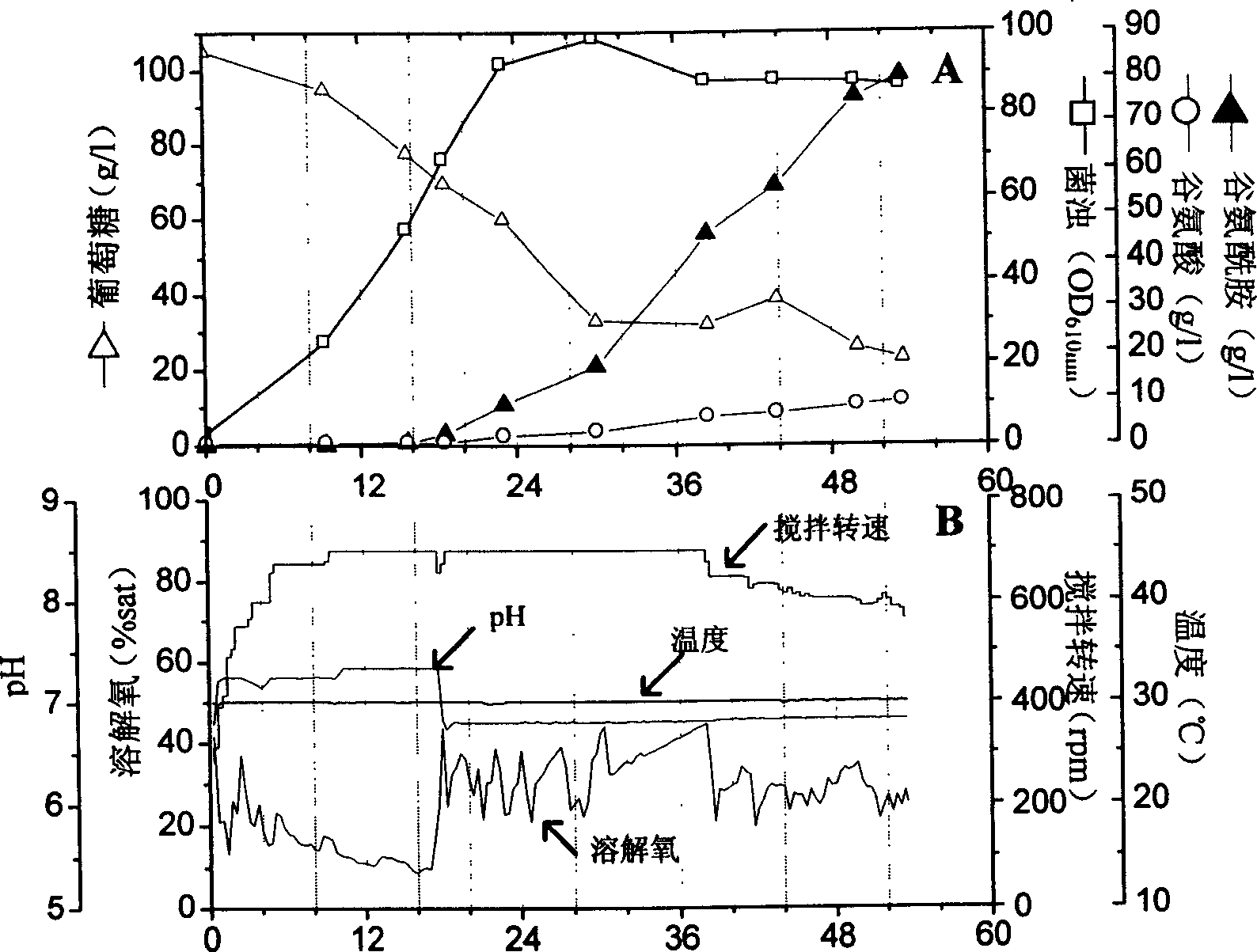

[0070] Embodiment 3: above-mentioned Corynebacterium glutamicum (Corynebacterium glutamicum) G32 CCTCCN0.M205028 bacterial strain fermentation produces glutamine

[0071]After culturing Corynebacterium glutamicum (Cornyebacterium glutamicum) G32 CCTCC NO.M205028 on the LB slope for 12 hours, connect 1 to 2 rings of bacterial lawn to a Erlenmeyer flask containing 20ml of liquid medium, at 30°C, at a speed of 100r / min, Liquid seeds were obtained after culturing for 9 hours under a reciprocating shaker with a stroke of 8 cm.

[0072] The above-mentioned liquid seeds are inserted into the fermentation medium at a volume percentage of 5% for ventilated and stirred culture, and high-concentration glutamine is produced by fermentation. Control the degree of saturation at 20% to 40%, and the fermentation time is 35-60 hours. Control the pH at the initial stage of fermentation to be 6.6. When the bacteria grow to the middle and late stages of the index (17-18 hours), the pH is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com