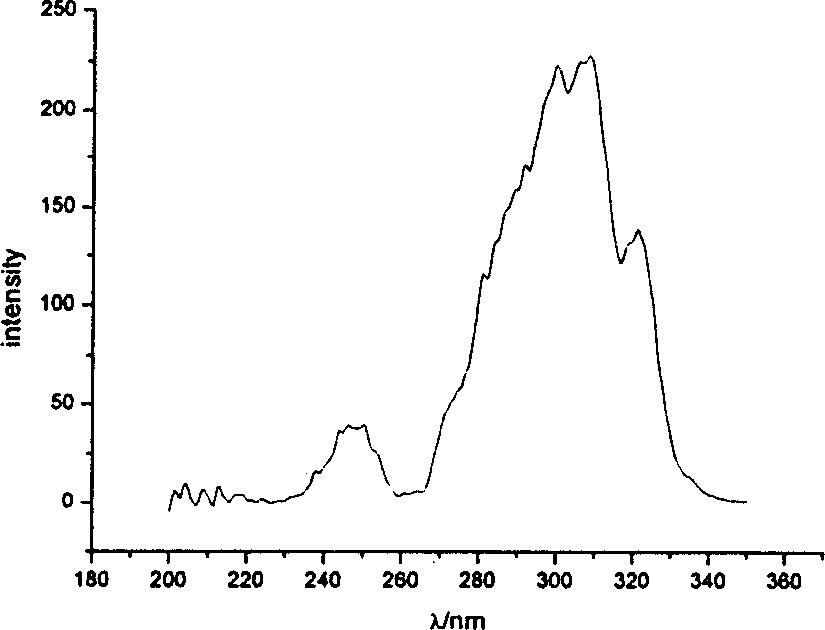

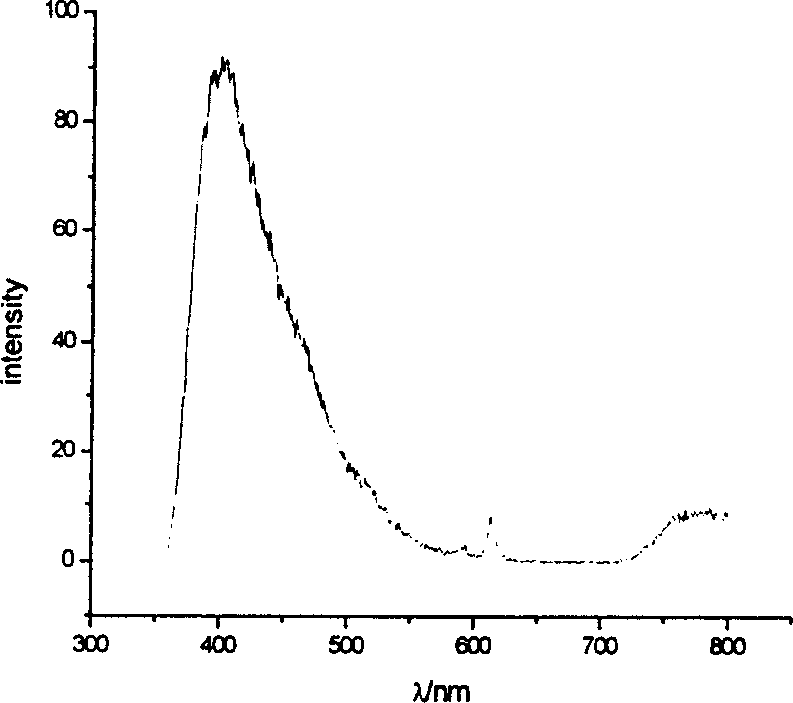

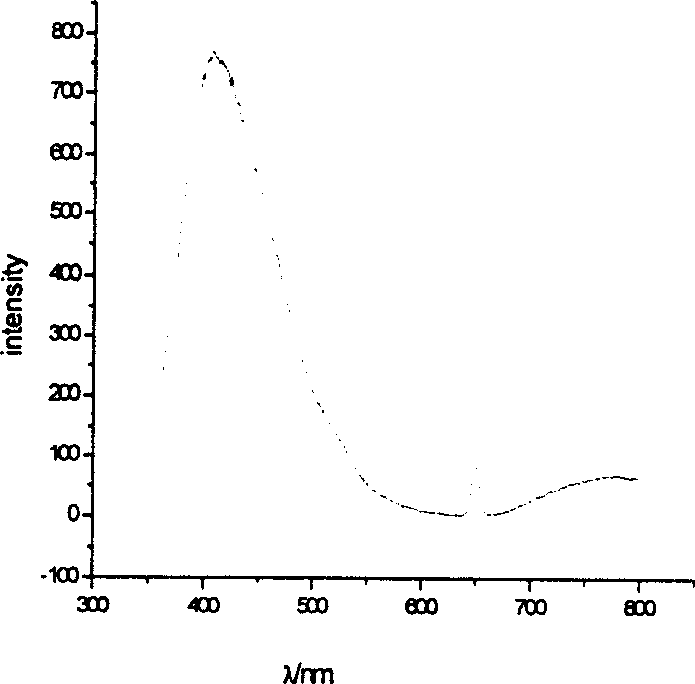

Nano rare earth optical transfer agent in bionic state, Nano rare earth optical transfer agricultural film in bionic state, and preparation method thereof

A technology of light-changing agricultural film and light-changing agent, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of not having the characteristics of imitation ecology, easy loss, fast light-turning attenuation, etc., to improve luminous efficiency and enhance dispersion performance, solve the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Will (La 0.9 SM 0.09 Eu 0.01 ) Cl 3 , α-naphthoic acid, 3-triethoxysilylpropyl dimethyl dodecyl ammonium chloride in a molar ratio of 1:4:2 at 20-40°C for 6 hours to obtain a new type of rare earth light conversion agent . Stir 0.5 parts of light-changing agent and 0.6 parts of clay with a cationic exchange capacity of 80meq / 100g at high speed in the presence of 20 parts of dispersion medium water to form a uniform material, and react at 20-200°C for 3-4 hours. The obtained product is washed, dried, and pulverized to become a functional organoclay compound (nano-mimetic rare earth light-changing agent); disperse 0.005 parts of nano-mimetic rare-earth light-changing agent in 100 parts of PVC polymer, blow molding or After tape-casting, the nano-imitation ecological rare earth light-converting agricultural film can be obtained.

Embodiment 2

[0033] Will (La 0.7 Gd 0.1 Eu 0.2 )NO 3 , p-toluic acid, 3-trimethoxysilylpropylmethylethylhexadecylammonium chloride in a molar ratio of 1:5:1 at 40-60°C for 4 hours to obtain a new type of rare earth agent. 1 part of light-changing agent and 10 parts of clay with a cationic exchange capacity of 90meq / 100g are stirred at high speed in the presence of 100 parts of ethanol as a dispersion medium to form a uniform material, and reacted at 60-70°C for 3-5 hours. After washing, drying and crushing, the obtained product is a functional organoclay compound (nano-mimetic rare earth light-changing agent); disperse 5 parts of nano-mimetic rare earth light-changing agent in 100 parts of PE, blow molding or casting After forming, the nano-imitation ecological rare earth light-converting agricultural film can be obtained.

Embodiment 3

[0035] Will (Ce 0.4 Y 0.2 Eu 0.4 ) Cl 3 , β-naphthoic acid, and 3-trimethoxysilylpropyldimethyloctadecylammonium bromide in a molar ratio of 1:8:2 were reacted at 150-200° C. for 3 hours to obtain a new type of rare earth light converting agent. 6 parts of light-changing agent and 7 parts of clay with a cation exchange capacity of 80meq / 100g are stirred at high speed in the presence of 200 parts of ethanol as a dispersion medium to form a uniform material, and reacted at 80-100°C for 4 hours. After washing, drying and crushing, the obtained product is a functional organoclay compound (nano-mimetic rare earth light-changing agent); disperse 4 parts of nano-mimetic rare earth light-changing agent in 100 parts of EVA, blow molding or casting After forming, the nano-imitation ecological rare earth light-converting agricultural film can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com