Ink jet dye capable of improving the service life of nozzle

A dye and inkjet printing technology, applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve problems such as clogged nozzles and nozzles that have not been completely resolved, and achieve the elimination of dangerous factors, not easy to deposit carbon, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

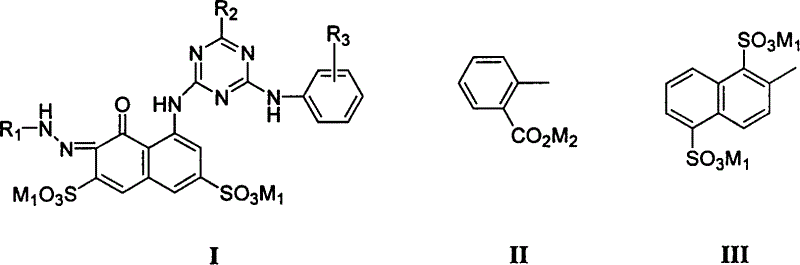

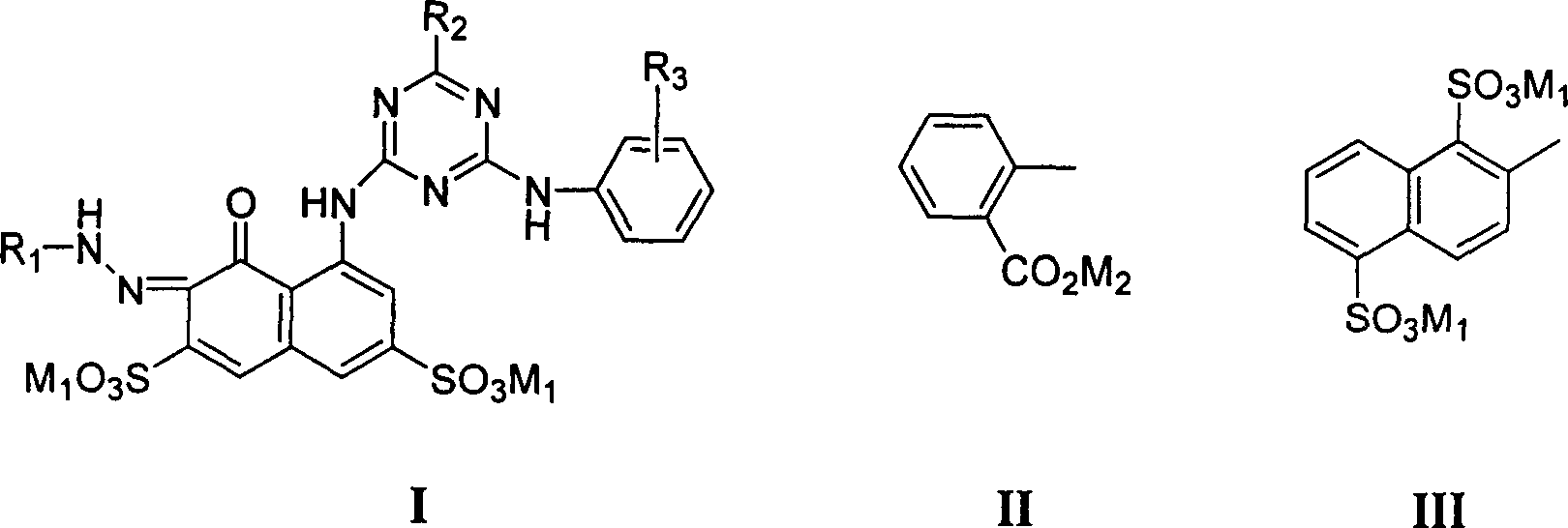

[0020] magenta dye k 2 (general structural formula I, R 1 for II, R 2 for N(CH 2 CH 2 Oh) 2 , R 3 for 2-COOM 3 ,M 1 , M 2 , M 3 For the synthesis of H or Na):

[0021] One condensation: 55.5 g of cyanuric chloride was added in 400 g of ice water, stirred and beaten for 30 minutes at 0° C., and then 15% H-acid (i.e. 1-amino-8 hydroxy-3,6-dinaphthalene was added within 1.5 hours) Sulfonic acid) aqueous solution (containing 102.3g of pure H-acid, adjust the pH to 6-6.2 with sodium carbonate, stir and react at 3-5°C for 3-5 hours, filter the solution to remove a small amount of solid impurities, and obtain a condensation solution.

[0022] Diazotization: Add 87.6g of 30% hydrochloric acid and 41.1g of anthranilic acid to 100g of ice water, stir below 10°C, add dropwise 30% sodium nitrite solution (containing 20.7g of pure sodium nitrite), at 10-15°C The reaction was stirred for 0.5 hours, and the solution was filtered to remove a small amount of solid impurities to obta...

Embodiment 2

[0029] magenta dye k 1 (general structural formula I, R 1 for II, R 2 for NHCH 2 CH 2 OH,R 3 for 2-COOM 3 ,M 1 , M 2 , M 3 For the synthesis of H or Na).

[0030] The synthesis process is the same as in Example 1, except that the 31.5g diethanolamine added in the triple coupling is changed to 18.3g ethanolamine to obtain 387g dye k 1 . The maximum absorption wavelengths of ultraviolet-visible spectrum in aqueous solution are 519 and 544nm.

[0031] 1 HNMR: δ DMSO (PPM)=3.4(2H, m), 3.6(2H, t, J=6.8), 4.9(2H, s), 6.9(1H, t, J=7.2), 7.2(1H, t, J=7.6) , 7.3(1H, t, J=7.2), 7.4(1H, s), 7.4(1H, s), 7.5(1H, t, J=7.2), 7.6(1H, t, J=7.2), 8.0( 2H, d, J = 7.2), 8.4 (1H, d, J = 7.2), 8.4 (1H, d, J = 8), 8.8 (1H, d, J = 8), 9.5 (1H, s), 12.9 (1H,s), 13.1(1H,s), 16.9(1H,s). The single peak at 16.9 indicates that this structure is a quinone hydrazone isomer. Electrospray mass spectrometry detection, M 1 , M 2 , M 3 Timed in H, k 2 The molecular mass should be 740. In ne...

Embodiment 3

[0033] dye k 0 (general structural formula I, R 1 for II, R 2 for OH, R 3 for 2-COOM 3 ,M 1 , M 2 , M 3 For the synthesis of H or Na):

[0034] The synthesis process is the same as in Example 1, except that the 31.5 g of diethanolamine added in the triple coupling is changed to 12.0 g of sodium hydroxide to obtain 368 g of dye k 0 . The maximum absorption wavelengths of ultraviolet-visible spectrum in aqueous solution are 517 and 541nm.

[0035] 1 HNMR: δ D2O (PPM)=6.9(1H, t, J=7.2), 7.1(1H, t, J=7.6), 7.3(1H, s), 7.4(1H, t, J=7.2), 7.4(1H, s) , 7.5 (1H, t, J = 7.2), 7.9 (1H, d, J = 7.2), 8.0 (1H, d, J = 7.2), 8.3 (1H, d, J = 7.2), 8.8 (1H, d , J=8), 9.1 (1H, s), 17.3 (1H, s). The single peak of 17.3 indicates that this structure is a quinone hydrazone isomer.

[0036] Electrospray mass spectrometry detection, M 1 , M 2 , M 3 In H time, dye k 0 The molecular mass should be 697. In negative mode, the electrospray mass spectrum has a base peak with a mass-to-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com