Method for preparing cyclohexane through benzene hydrogenation

A technology for the hydrogenation of cyclohexane and benzene, which is applied in the fields of hydrogenation to hydrocarbons, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., which can solve the problems of easy carbon deposition, low catalytic activity, and catalytic stability low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0063] Preparation of Raney Nickel Catalysts Supported by Polymer Materials

[0064] (1) Weigh 100g of nylon-66 particles (Baling Petrochemical, BL2340-H) and place it in the nickel-aluminum alloy powder. In the nickel-aluminum alloy, the Ni content is 48wt%, and the aluminum content is 52wt%. Molding at 250°C and pressure of 7MPa for 10min, take out and cool, sieve, and sieve out the spherical particles, the surface of the particles is completely covered with nickel-aluminum alloy powder, and the supported catalyst is obtained, weighing 350g;

[0065] (2) Configure 400g of 20% NaOH aqueous solution with deionized water, add 40g of the supported catalyst obtained in step (1), keep the temperature at 85°C, and filter the solution after 4 hours to obtain the activated supported catalyst A. In the final catalyst A The loading of nickel metal is about 45wt%. After washing to near neutrality, it is stored in deionized water for later use.

preparation example 2

[0067] Preparation of Composite Hydrogenation Catalyst

[0068] (1) 100 mass parts of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 mass parts of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass were stirred evenly to obtain an epoxy system;

[0069] (2) Take by weighing 40g of the epoxy system prepared in step (1) and 180g nickel-aluminum alloy powder and fully stir and mix, the Ni content in the nickel-aluminum alloy is 48wt%, and the aluminum content is 52wt%. In the mould, use a flat vulcanizer to press for 30s at a temperature of 120°C and a pressure of 7MPa, and use a flat vulcanizer to press for 90s at a temperature of 150°C and a pressure of 7MPa, and take it out after cooling to obtain a granular catalyst precursor;

[0070] (3) Measure 100ml of catalyst precursor, put it into a tube-type high-temp...

Embodiment 1

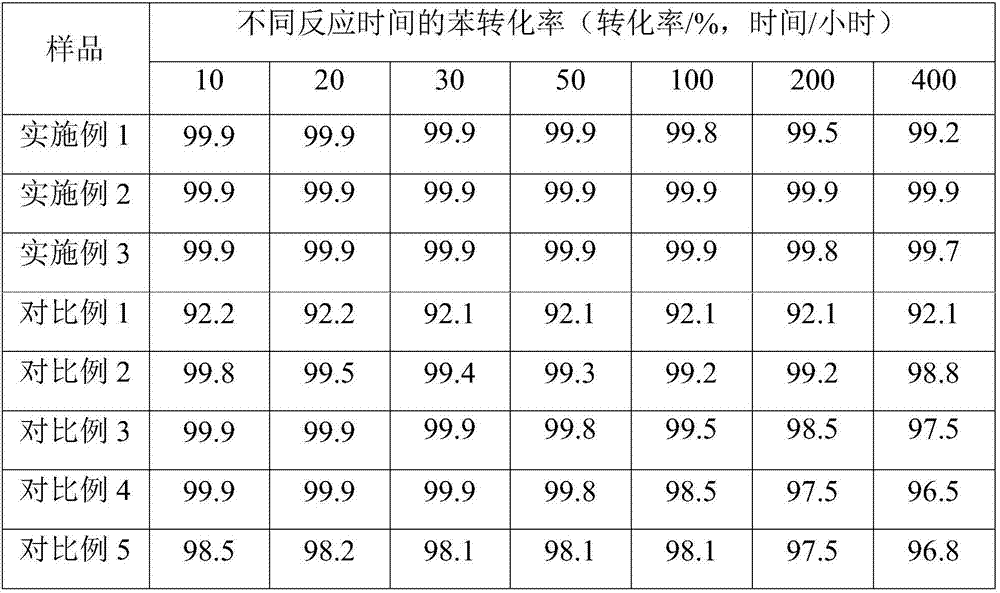

[0074] 5ml of catalyst A is loaded into the stainless steel first reactor with internal diameter of 14mm, the second reactor is filled with 5ml of catalyst B (two reactors connected in series), the reaction gas is industrial grade hydrogen, and the flow rate of hydrogen is 300mL / min, and the reaction liquid The raw material is a mixture of benzene and product cyclohexane, wherein the benzene content is 50wt%, and the sample is injected by a micropump, the liquid flow rate is 0.5mL / min, the temperature of the first reactor is 120°C, the temperature of the second reactor is 180°C, and the reaction pressure is 4.0 MPa. The reaction product was detected and analyzed by Agilent 7890A gas chromatography with FID detector. The results of benzene hydrogenation reaction are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com