Magnesium alloy low-pressure casting method

A low-pressure casting and low-pressure casting machine technology, applied in the field of low-pressure casting of magnesium alloys, to achieve the effects of reducing production costs, reducing environmental pollution, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

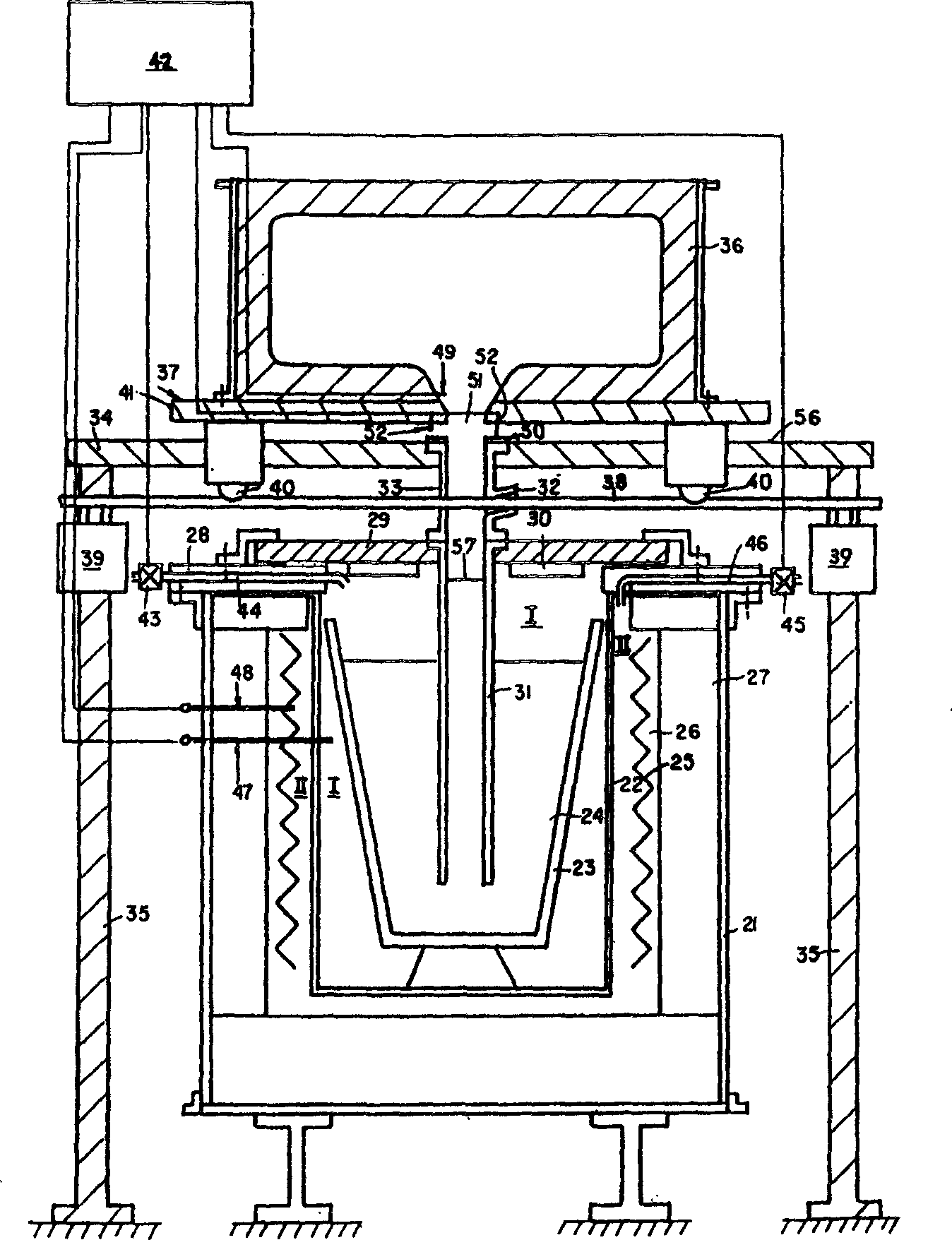

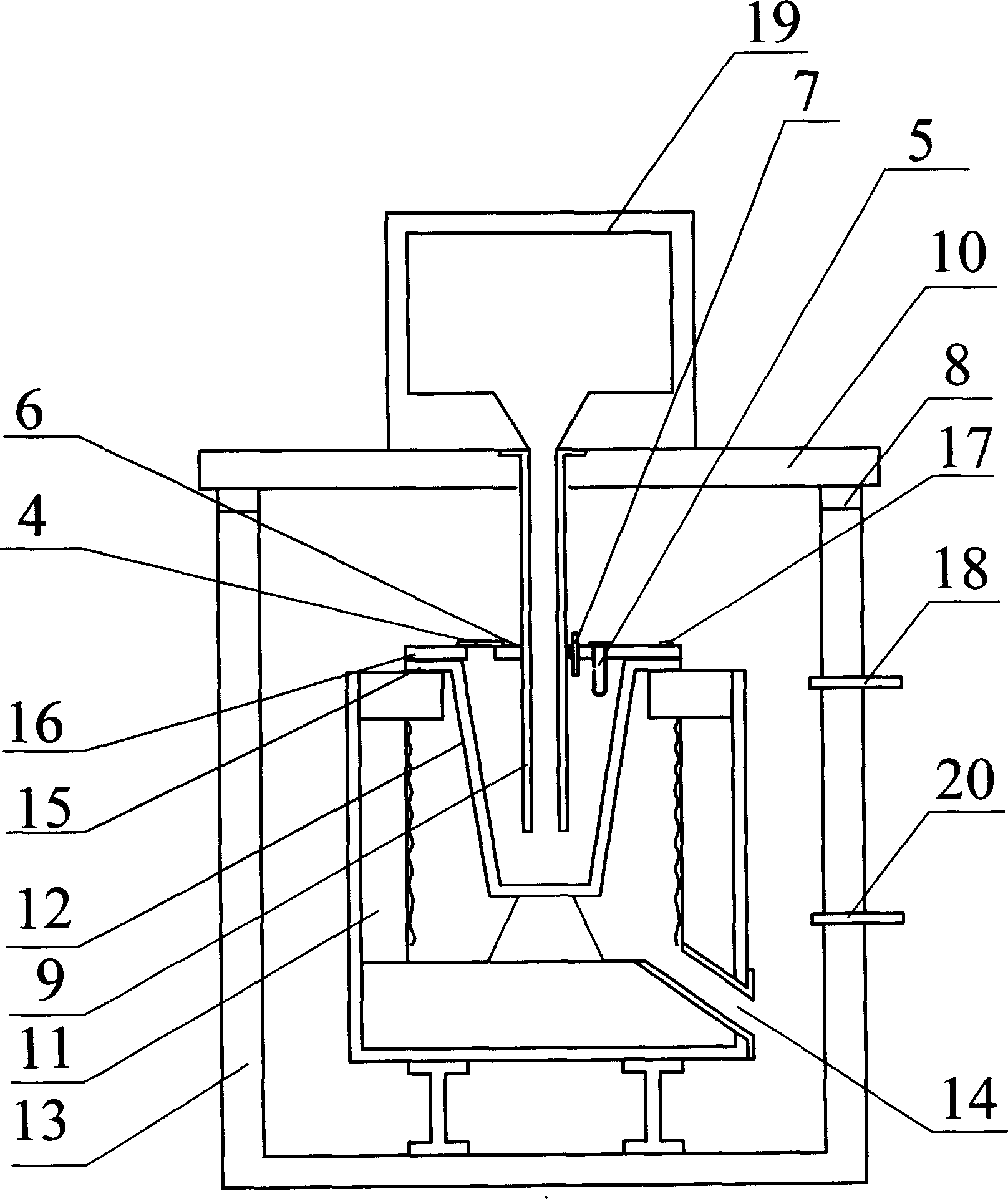

[0046] The host of the magnesium alloy low-pressure casting machine includes a holding furnace 11 , a crucible 12 , a sealing cover 10 , a pressure tank 13 , a riser pipe 9 and a casting mold 19 . Holding furnace 11 is installed in pressure tank 13, and is supported by I-shaped support. A vent 14 is arranged on the side wall of the holding furnace 11. The crucible 12 is installed in the holding furnace 11 , and the upper edge 15 of the crucible 12 overlaps with the upper port of the holding furnace 11 .

[0047] When the magnesium alloy liquid in the crucible has been refined and the temperature is adjusted to the casting temperature, start to place protective gas generating substances, namely protective agents 1, 2 and 3. Protective agent 1 is composed of 100g of sulfur powder and 200g of boric acid mixed uniformly. The protective agent 1 is loaded into a container 5 with an inner cavity with a height-to-diameter ratio of 2. The container 5 is a double-layer cylinder made ...

Embodiment 2

[0050] The second embodiment is basically the same as the first embodiment, except that the protective agent 1 is made by mixing 70g of sulfur powder and 250g of boric acid. Protectant 2 consists of 100g pyrite powder and 100g dry charcoal powder. Protective agent 3 is made up of 100g sulfur powder and 300g boric acid, and covers 20mm thick 100-200 mesh quartz sand in the container that holds protective agent 3. Two containers for containing protective agent 3 are arranged on both sides of the rising liquid pipe hole 6 of the crucible cover, apart from the 230mm place of the rising liquid pipe hole.

Embodiment 3

[0052] Embodiment 3 is basically the same as Embodiment 1, except that the protective agent 1 is made by mixing 120g of sulfur powder, 100g of boric acid and 200g of 70-140 mesh magnesia. Protective agent 2 is composed of 50g of sulfur powder, 100g of coke powder and 150g of pyrite powder. First, 100g of coke powder is evenly sprinkled on the sulfur powder, and then 150g of pyrite powder is evenly sprinkled on the top. Protective agent 3 is composed of 160g of yellow Composed of iron ore powder and 80g 70-140 mesh quartz sand, two containers containing protective agent 3 are respectively placed on both sides of the observation hole on the crucible cover 5 and the center line of the riser hole, 200mm away from the riser hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com