Casting production line

A casting production line and foundry sand technology, applied in foundry workshops, casting equipment, casting molding equipment, etc., can solve the problems of high work intensity, poor operating environment, and high labor costs, and achieve reduced labor costs, compact structure, and simple control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0029] Such as image 3 , a casting production line based on the above-mentioned fully automatic sand box molding equipment, including an automatic sand supply device composed of a sand storage device 2 and a sand transport device 3, and also includes a fully automatic sand box molding equipment, a case handling manipulator 4, and a pouring line 5 , automatic pouring ladle 6, automatic box dropping machine 7, sandbox frame conveyor belt 8, casting sand separator 9, sand collection device 10, sand return conveyor belt 11, magnetic separator 12 and mixer 13;

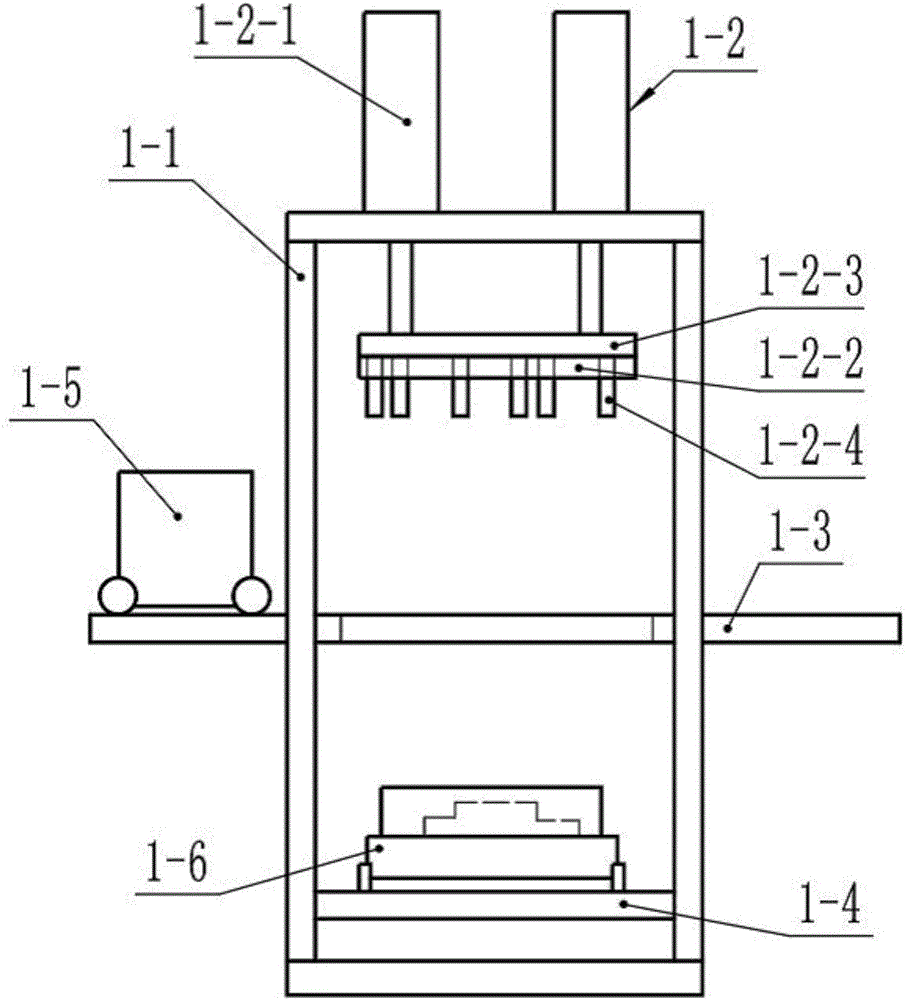

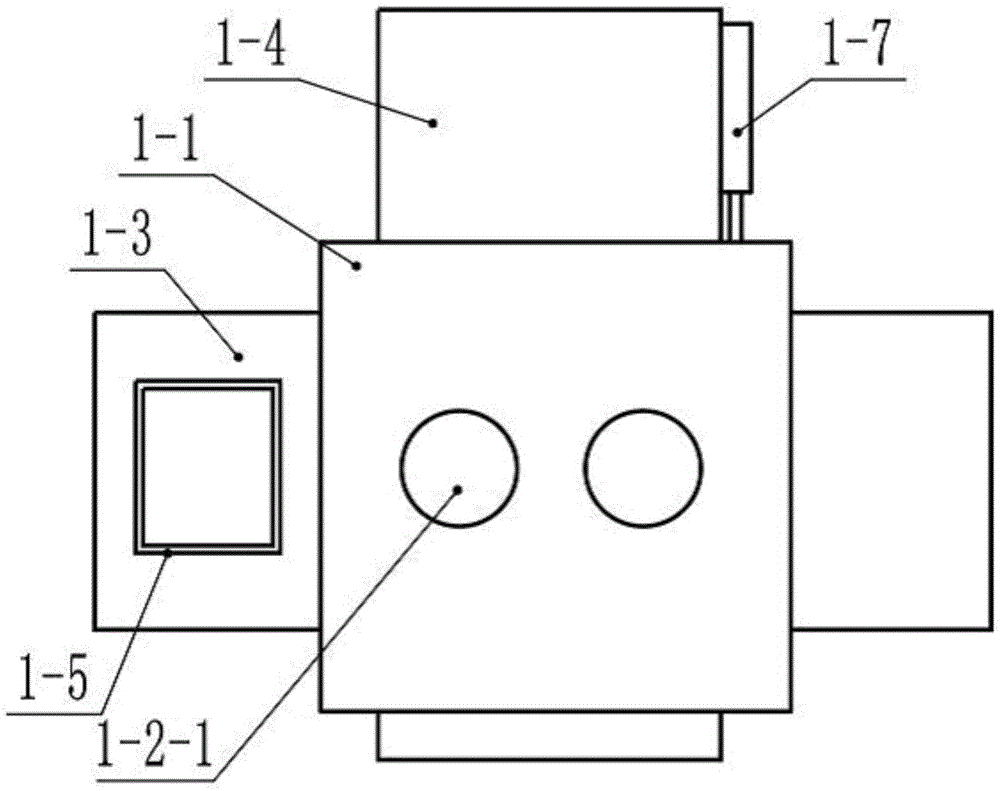

[0030] Such as figure 1 and 2 As shown, the full-automatic sand box molding equipment has a frame body 1-1, a sand pounding device 1-2 is installed on the top of the frame body 1-1, and a horizontally arranged adding machine is installed in the middle of the frame body 1-1 A sand track 1-3, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com