Low-pressure die casting machine for magnesium alloy automobile wheels

A low-pressure casting machine and magnesium alloy technology, which is applied in the field of low-pressure casting machines, can solve the problems of low casting quality of magnesium alloy products, inability to monitor mold temperature in real time, and affect the economic benefits of enterprises, so as to keep the liquid surface pure and avoid sediment flooding The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

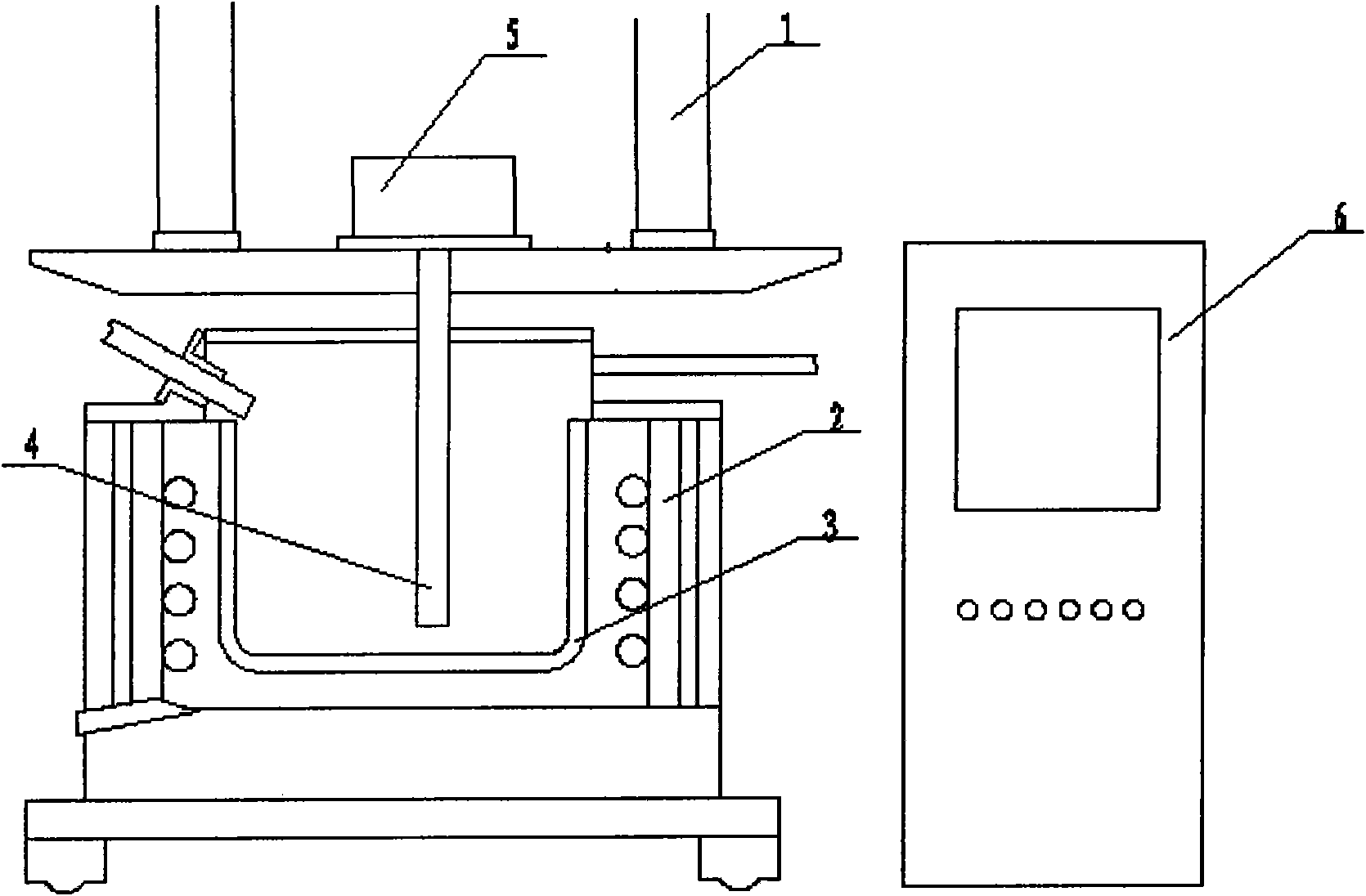

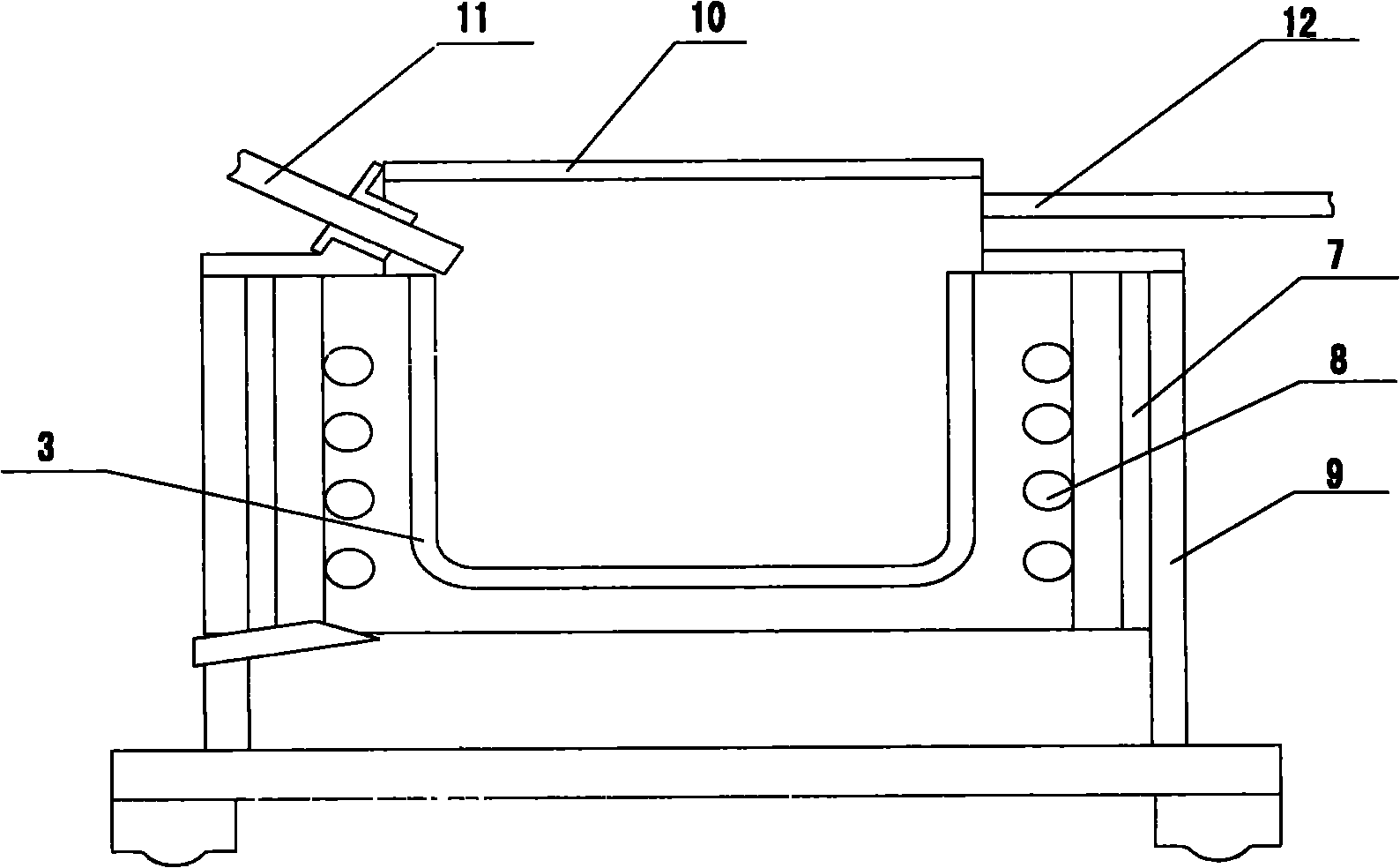

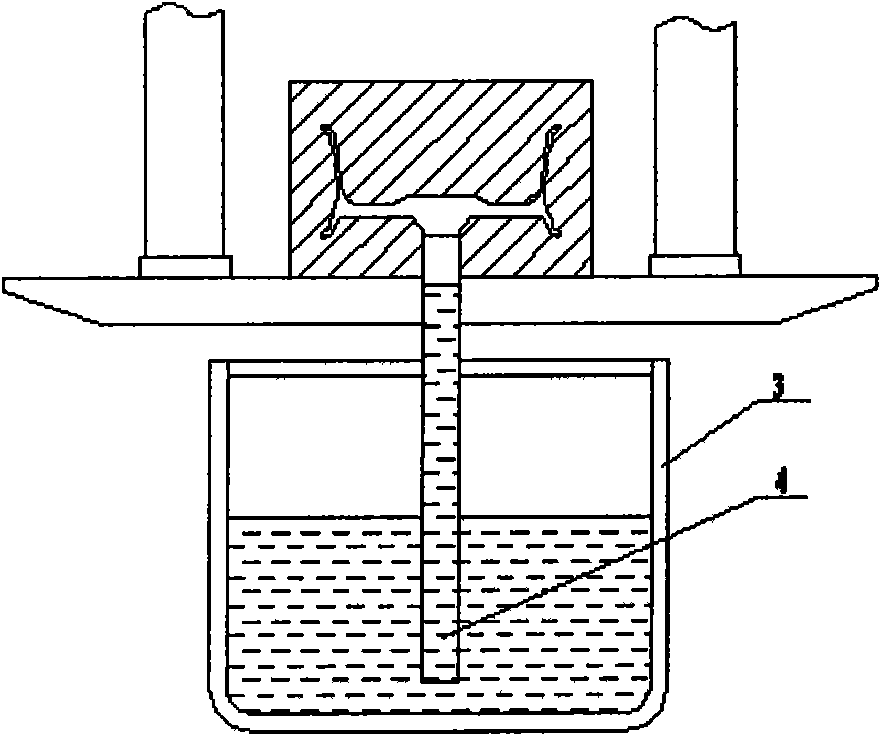

[0012] combine figure 1 , figure 2 , the magnesium alloy automobile wheel low-pressure casting machine of the present invention comprises a casting machine main frame 1, a holding furnace 2, a mold 5, and a real-time casting monitoring platform 6, and the real-time casting monitoring platform is used for raising liquid pressure, boosting pressure, and filling time during casting. , pressurization time, pressure holding time, mold opening and closing times, and the position parameters of the magnesium alloy liquid level in the holding furnace are set and monitored; it also includes the liquid riser 4, which will be set above the casting host 1 The mold 5 is connected to the holding furnace 2; the holding furnace 2 includes a furnace lining 7, an electric heating wire 8, a furnace shell 9, a crucible 3, a furnace cover 10, a fully enclosed liquid adding device 11 and a protective gas inlet 12; the furnace shell 9 The crucible 3 is arranged inside, the furnace lining 7 is betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com