Synthesis methods, complexes and delivery methods for the safe and convenient storage, transport and application of compounds for inhibiting the ethylene response in plants

A technology of complexes and compounds, which is applied in the fields of extended cut flowers, transplanted plants and plant food, ornamental plants, potted plants, and regulation of plant physiology. It can solve problems such as impure reaction products and unsuitable plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

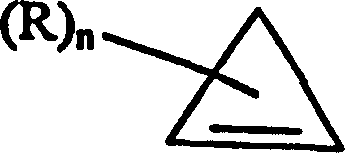

Image

Examples

Embodiment 1

[0096] Embodiment 1: the synthesis of methylcyclopropene

[0097] At room temperature, nitrogen gas (purity 99.95%) was pumped into a chamber containing sodium amide powder (90%-NaNH 2 ) or lithium diisopropylamide powder (97%-[(CH 3 ) 2 CH] 2 Nli) in the nitrogen container (35 "X28 "X32"). Another separate powder addition container is also fed into nitrogen. Because Lewis base reacts with air, nitrogen is used to eliminate the pollution before the synthesis reaction. In the powder addition container Contain an inert atmosphere, add 365-1100 gram of sodium amide (or the diisopropylamine lithium of equimolar concentration), it is advisable that the amount is bigger.In a nitrogen box, weigh an appropriate amount of Lewis base, nitrogen is to eliminate oxygen And the spontaneous ignition of alkali. In the operation steps of alkali, special attention must be paid to safety.

[0098] After adding the Lewis base powder, close the hole for ventilation on the powder addition co...

Embodiment 2

[0106] Example 2: Manufacture of methylcyclopropene with 3-bromo-2-methylpropene and lithium diisopropylamide

[0107] In a nitrogen atmosphere, approximately 0.1-0.5 moles of lithium diisopropylamide were placed in a 2-liter container. Then, 100 ml of a non-volatile organic solvent, such as dry mineral oil, is added to the container. Next, about 0.1-0.5 mole of 3-bromo-2-methylpropene is placed in the container. The molar ratio of lithium amide and methylpropene halide was 1:1. React until the solution is no longer exothermic. Next, about 0.1-0.5 mole of polar solvent, such as water, is put into the container.

[0108] The headspace of the reaction is purged with a scrubber or nitrogen gas through the condenser and the condenser tube, and a vacuum system is connected to a bottle containing about 50-200 grams of α-cyclodextrin and 50-200 grams of water, and the buffer range is between pH 4- 6. The temperature of the condenser tube is maintained at about 0-10°C, while th...

Embodiment 3

[0111] Example 3: Release of methylcyclopropene from cyclodextrins

[0112] In order to release methylcyclopropene from cyclodextrin molecular ligand formulations for the treatment of plants, the first thing is to place the plants in a closed environment, preferably at elevated temperature, preferably from 13°C to 24°C. When dealing with crops such as carnations, the amount of methylcyclopropene used is 100-500ppb (the concentration of methylcyclopropene in the released space accounts for parts per billion). For complexes of molecular ligand preparations releasing methylcyclopropene or other compounds capable of inhibiting the plant's ethylene response, the amount used will depend on the species of plant being treated and the particular form of complex being used. Before the active compound is released, the space to be treated is closed and an air flow is created so that all plants in the closed space can be treated. Next, the methylcyclopropene / α-cyclodextrin is put into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com