Optical waveguide article including a fluorine-containing zone

A product and optical technology, applied in the field of waveguide, can solve problems such as amplification and harmful power conversion efficiency, and achieve the effects of low loss, low background attenuation, and wide gain spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0081] Example 2 - Fluorine Reservoir

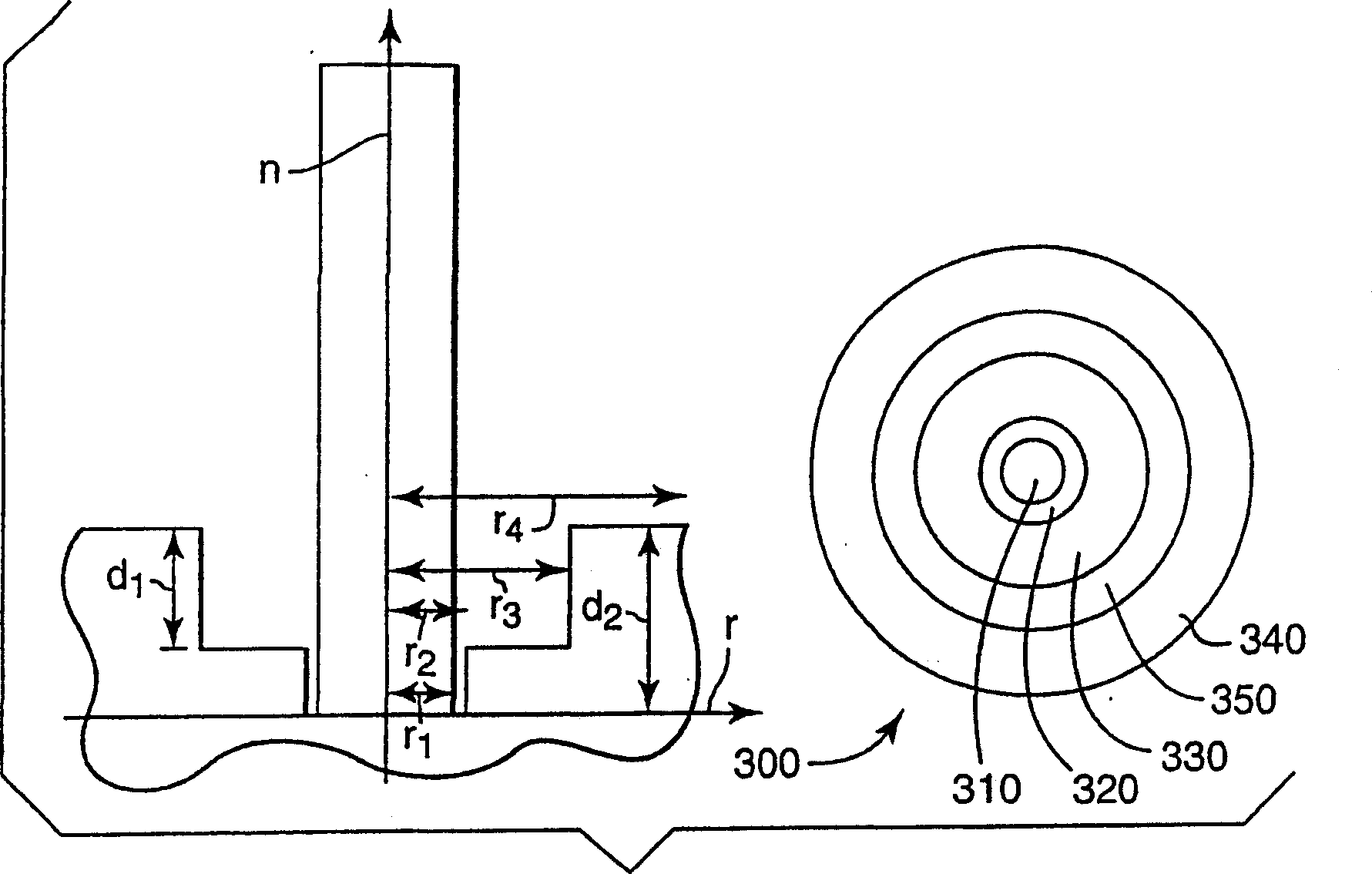

[0082] have something like image 3 The shown distribution of DCLR preforms was fabricated by MCVD techniques. use SiF 4 (30sccm), POCl 3 (100sccm) and SiCl 4 (950sccm) five deposition passes were made to prepare the inner cladding, and SiF 4 (flow rate is 350sccm), POCl 3 (100sccm), and SiCl 4 (350 sccm) A sixth deposition pass was made to give a fluorosilicate reservoir region with -4 mol% fluorine. Its core is lanthanum aluminum silicate doped with erbium. The flattened preform is drawn and segmented, elongated, and overflattened. Fiber was drawn and characterized in the same manner as in Example 1. Wavelength dispersive X-ray analysis of a very small amount of preform gave a fiber with >0.5 mol% (>0.15 wt%) fluorine in the fiber, with ~4 mol% fluorine rings and an inner cladding with ~2.1 mol% fluorine.

[0083] optical fiber

type

f core (in a very small amount

preform core

Fluorine in

f rin...

example 3

[0086] Example 3 - L-band fiber with and without fluorine reservoir

[0087] Fibers suitable for L-band were fabricated as in Examples 1 and 2. Both fibers have nominal dopant and modifier cation concentrations. Data on preforms and optical fibers are shown below:

[0088] optical fiber

example 4

[0089] EXAMPLE 4 - COMPARISON OF THE EFFECT OF DIRECT DOPING HEAT TREATMENT TO FLUORINE RESERVOIR DESIGNED FIBERS

[0090] The present invention also provides a method for adjusting the distribution of fluorine in the radial direction. The radial distribution of the coefficient of thermal expansion (CTE) and viscosity through the diffusion of fluorine from the outer region of the core to the core is provided in the present invention.

[0091] The diffusion equation can be solved for the case of diffusion from a distributed source in cylindrical coordinates. The radial coordinate is r, the time is t, and the concentration distribution is C(r, Dt). The initial concentration Co is distributed on the vector r 1 and r 2 on the casing. The diffusion coefficient D is assumed to be independent of concentration. The derivation of this equation can be found in Carslaw and Jaeger, Heat Conduction in Solids (1948).

[0092] C ( r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com